A kind of method for preparing hydroxyethyl cellulose

A technology of hydroxyethyl cellulose and cellulose, applied in the field of cellulose, can solve the problems of unavoidable occupational health risks of acute poisoning, large amount of organic solvents, low production efficiency, etc., so as to reduce hidden safety hazards and occupational health risks, improve The effect of high production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

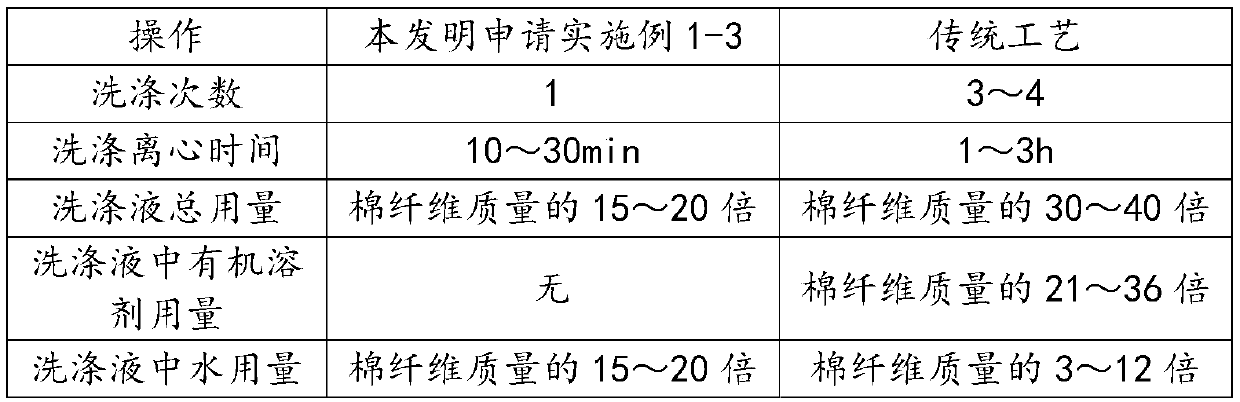

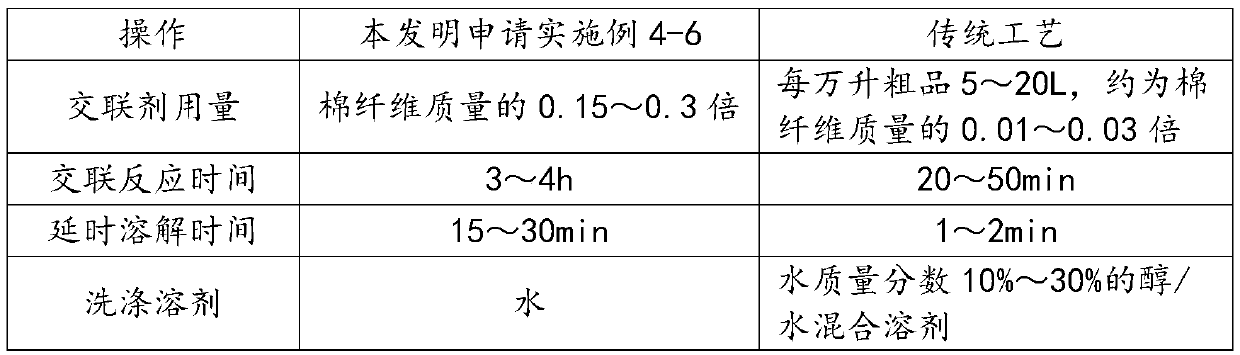

Method used

Image

Examples

Embodiment 1

[0025] The method for preparing hydroxyethyl cellulose provided in this embodiment comprises the following steps:

[0026] A. Add 500kg of sodium sulfite and 160kg of caustic soda to the reaction kettle, mix them evenly with the solvent, add 700kg of cotton fibers, and carry out alkalization reaction at 18°C for 1h; add 800kg of ethylene oxide, and carry out etherification reaction at 65°C for 2.5h , to obtain crude hydroxyethyl cellulose. Add sodium sulfite 300kg then in reactor, after mixing, add hydrochloric acid and unnecessary alkali, contain sodium chloride 230kg (theoretical calculation value) in the slurry I that obtains;

[0027] B. Slurry I enters the centrifuge for solid-liquid separation to obtain powder I and solvent;

[0028] C. The powder Ⅰ enters the dryer, and the solvent is recovered until no fraction is evaporated to obtain the powder Ⅱ;

[0029] D. Put the powder material II into the washing tank, add 14T of soft water with a temperature of 18°C and a...

Embodiment 2

[0035] The method for preparing hydroxyethyl cellulose provided in this embodiment comprises the following steps:

[0036] A. Add 160kg of solvent and caustic soda to the reaction kettle, after mixing, add 700kg of cotton fiber, and carry out alkalization reaction at 18°C for 1h; add 800kg of ethylene oxide, and carry out etherification reaction at 65°C for 2.5h to obtain hydroxyl Ethyl cellulose crude product, after adding acetic acid to neutralize unnecessary alkali, contains sodium acetate 320kg (theoretical calculation value) in the slurry I that obtains;

[0037] B. Add 600 kg of disodium hydrogen phosphate into the reaction kettle, stir for 20 minutes, and obtain slurry II;

[0038] C. Slurry II enters the centrifuge for solid-liquid separation to obtain powder I and solvent;

[0039] D. The powder Ⅰ enters the dryer, and the solvent is recovered until no fraction is evaporated to obtain the powder Ⅱ;

[0040]E. Put the powder material II into the washing tank, add 1...

Embodiment 3

[0045] The method for preparing hydroxyethyl cellulose provided in this embodiment comprises the following steps:

[0046] A. Add 160kg of solvent and caustic soda to the reaction kettle, add 700kg of cotton fiber after mixing, and carry out alkalization reaction at 18°C for 1 hour. Add 800kg of ethylene oxide, carry out etherification reaction at 65°C for 2.5h, and obtain crude hydroxyethyl cellulose. After adding nitric acid to neutralize unnecessary alkali, contain sodium nitrate 340kg (theoretical calculation value) in the slurry I that obtains;

[0047] B. Add 200 kg of disodium hydrogen phosphate and 500 kg of sodium sulfite into the reactor, stir for 30 minutes to obtain slurry II;

[0048] C. Slurry II enters the centrifuge for solid-liquid separation to obtain powder I and solvent;

[0049] D. The powder Ⅰ enters the dryer, and the solvent is recovered until no fraction is evaporated to obtain the powder Ⅱ;

[0050] E. Put the powder material II into the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com