Method for surface solid co-permeation on blade of cutter

A cutting tool, solid technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve problems such as low bonding strength, blade deformation, peeling, etc., to improve wear resistance and corrosion resistance, hardness and wear resistance. , The effect of stable tool performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation of self-sharpening tools is mainly to realize the change of hardness on the cutting edge section, resulting in the difference of wear amount. In order to realize the change of material hardness, the existing technology mainly adopts surface strengthening processes such as chemical heat treatment, surfacing welding, spraying, cladding, etc. to obtain the surface. Blades with different hardness.

[0040] Solid co-infiltration treatment is a new material treatment method. At present, more researches are on boronizing treatment, boron and nitriding treatment, etc., but less research on carbon, nitrogen and boron three-component co-infiltration. Existing studies have shown that when carbon-nitrogen-boron ternary co-infiltration is carried out, the infiltration amount of boron is very small, and it is difficult to form a boride layer on the surface. However, there is no report on the preparation of self-sharpening knives by solid co-infiltration.

[0041] Bas...

Embodiment 1

[0056] Example 1: Surface solid co-infiltration treatment at the cutting edge of the tool

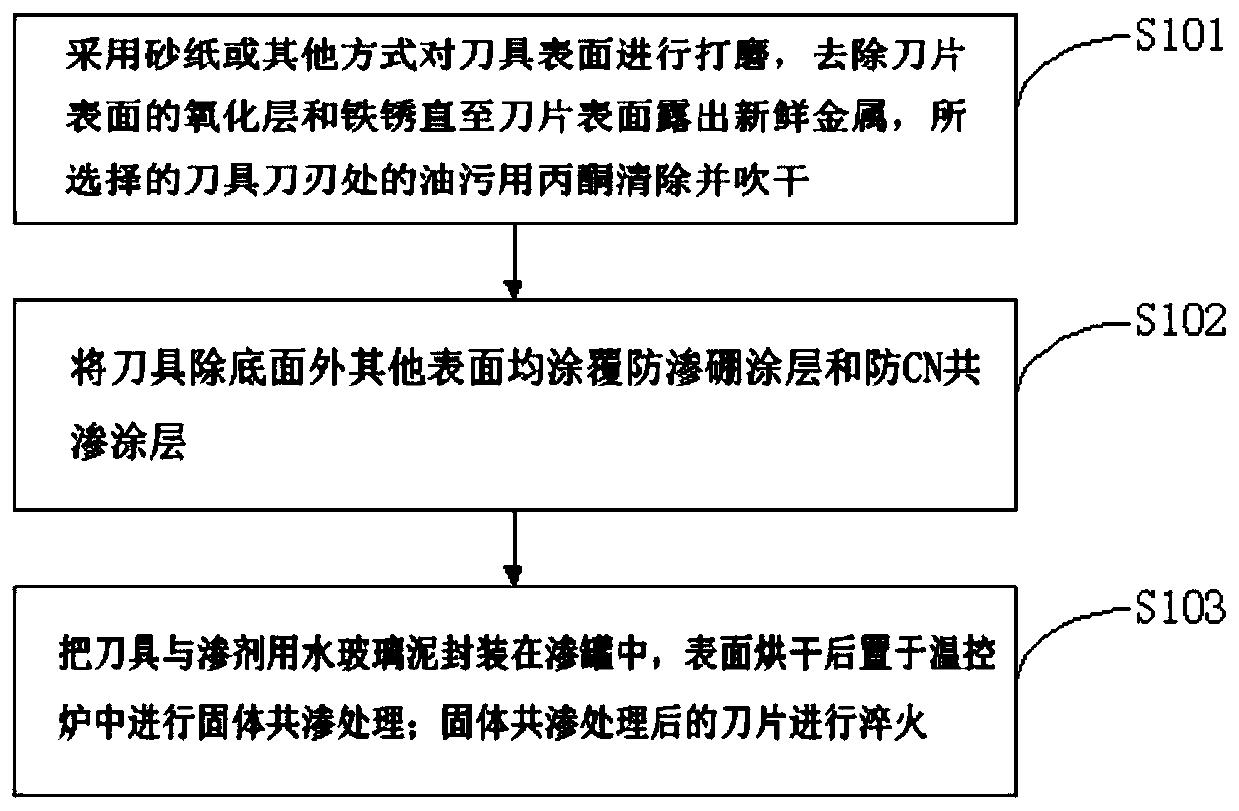

[0057] The schematic flow chart of the method of co-infiltration of surface solids at the cutting edge of the tool is as follows figure 1 As shown, the method includes:

[0058] S101: Grind the surface of the tool with sandpaper or other methods to remove the oxide layer and rust on the surface of the blade until fresh metal is exposed on the surface of the blade. Remove the oil stains on the blade of the selected tool with acetone and blow dry. Specifically, after selecting a tool that requires solid co-infiltration, dust, oil stains, oxide layers and other dirt on the surface of the tool are cleaned, and then the tool is dried.

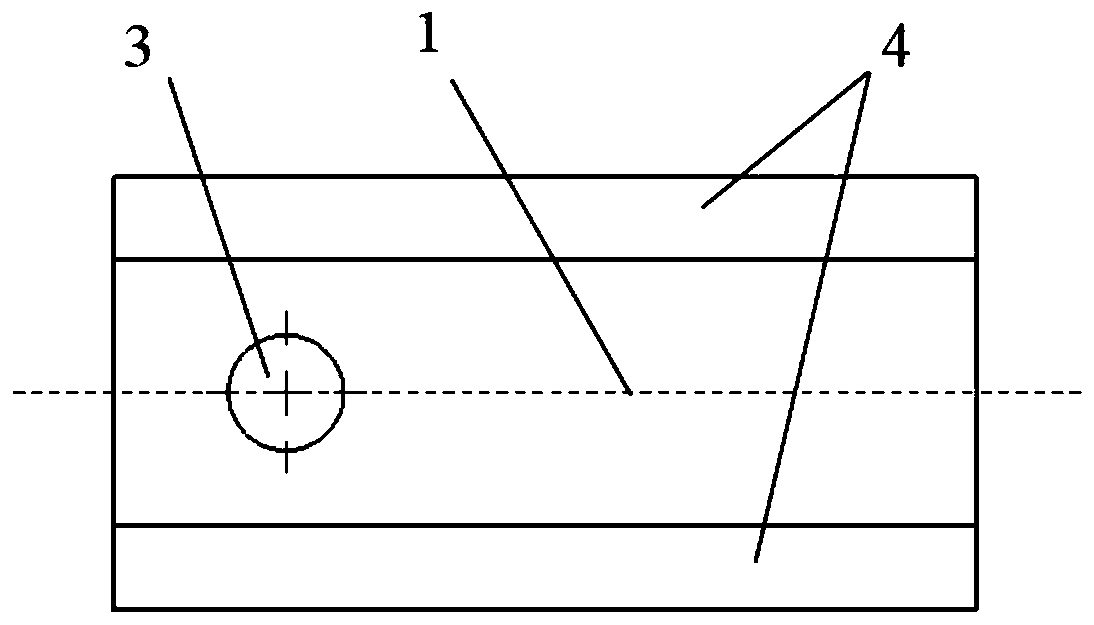

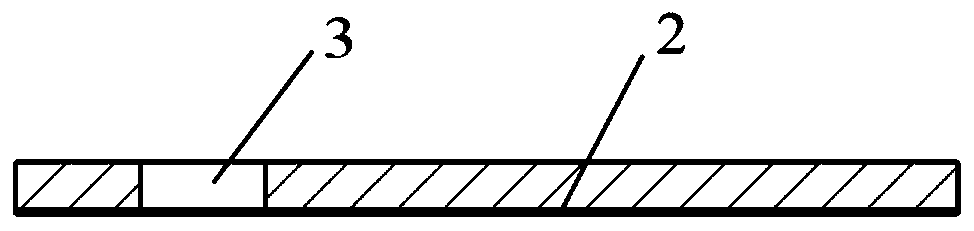

[0059] S102: Select the bottom surface of the pretreated tool as the solid co-infiltration treatment area, and coat the other areas of the tool with anti-boridization coating and anti-carbonitriding coating; wherein, the thickness of the anti-boridization co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com