Production system and method for distributed injection and exhaust passage narrow strip coal underground gasification furnace

An exhaust channel and underground gasification technology, which is applied in coal gasification, underground mining, construction, etc., can solve problems such as unstable gas production, unstable gas production process, and operation accidents, without destroying the integrity and airtightness of coal seams The effect of non-drilling coal seam integrity and tightness, good tightness and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

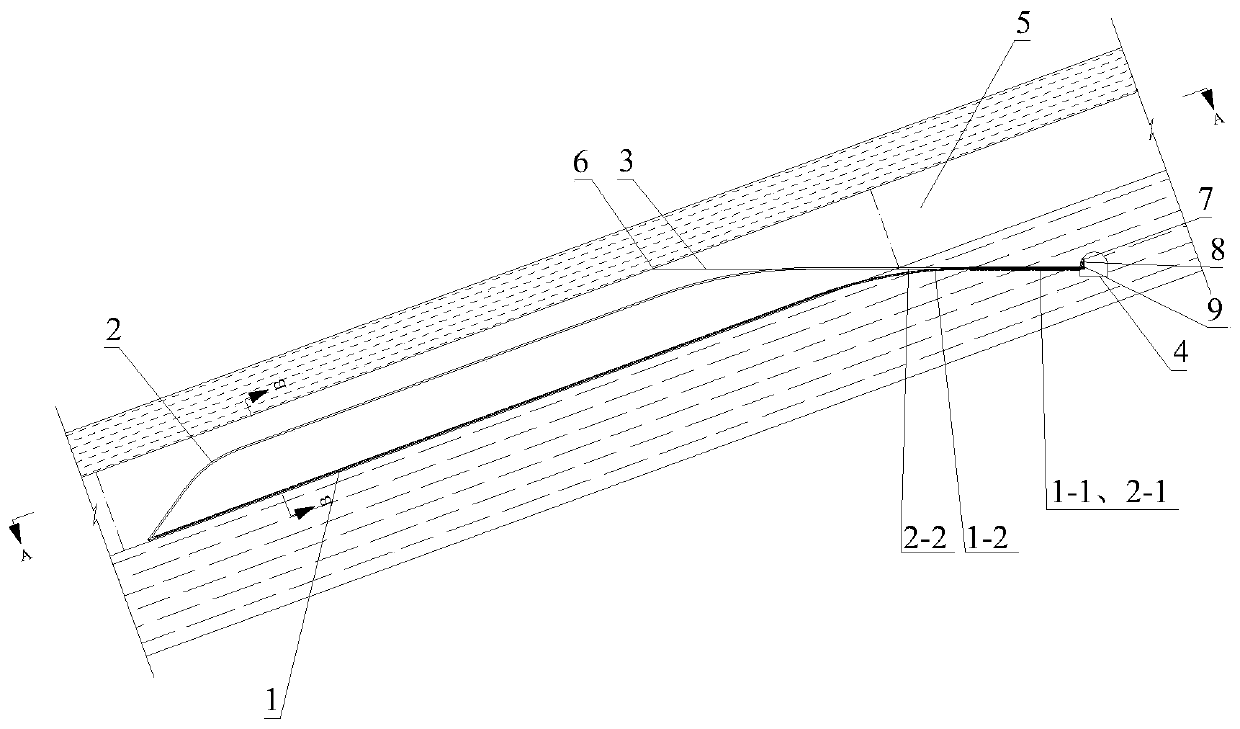

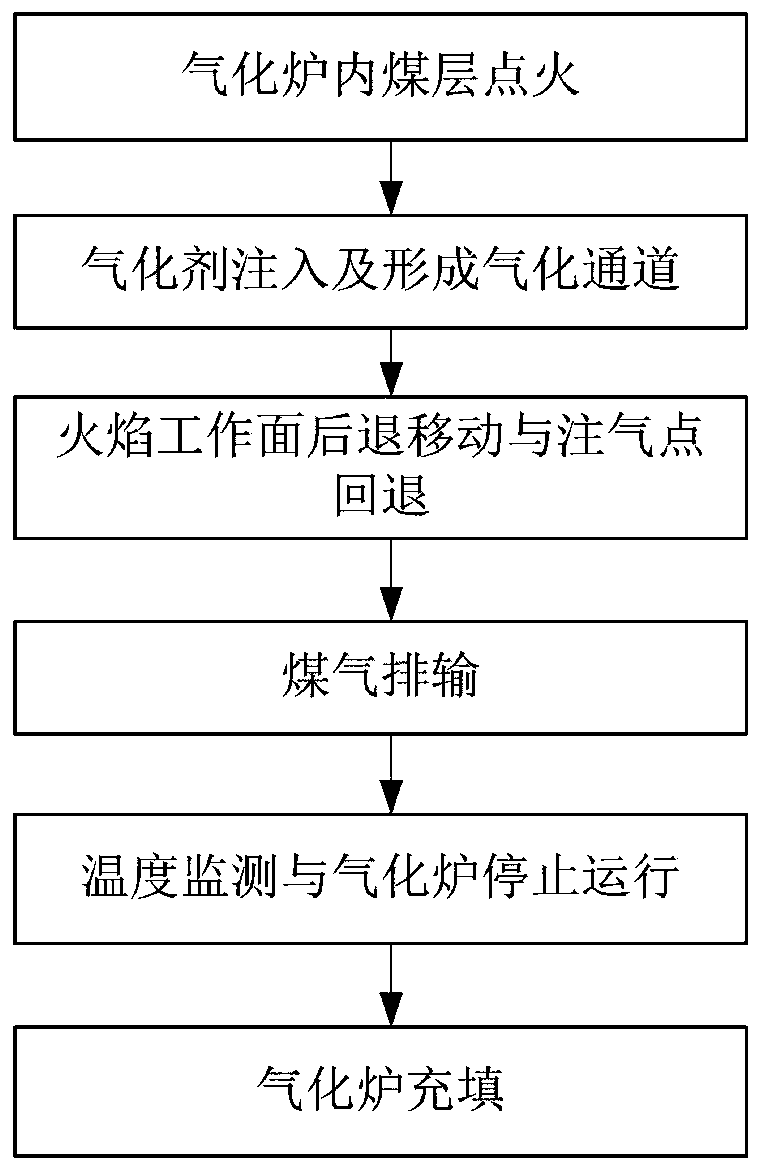

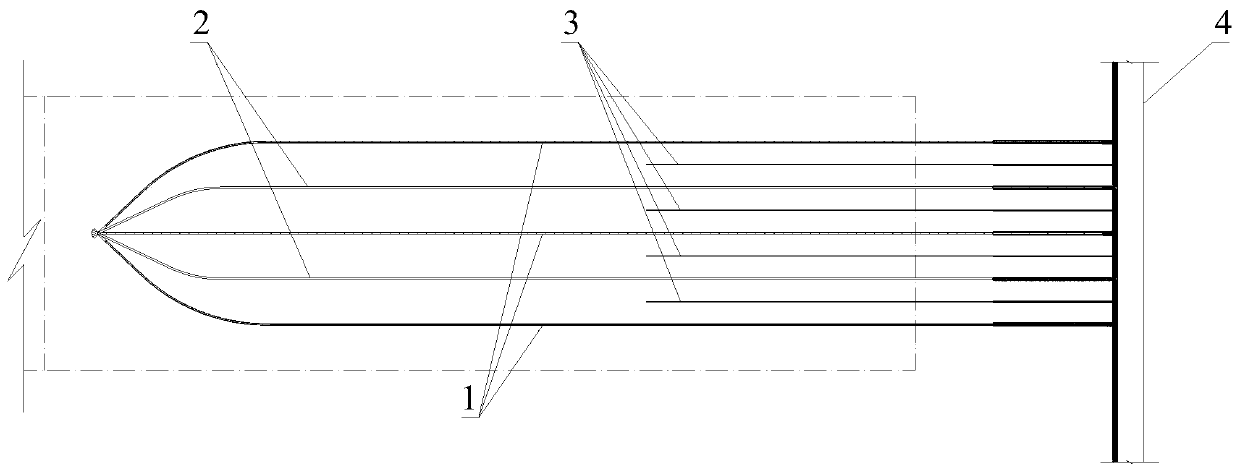

[0139] The embodiment of the present invention provides an underground coal gasifier with narrow strips of distributed injection and exhaust channels (taking the arrangement of three gas injection channels and two exhaust channels as an example). like figure 1 and Figure 3-8 , the underground gasifier includes three gas injection passages 1 , two exhaust passages 2 and four temperature monitoring boreholes 3 arranged in a coal seam 5 . The gas injection channel 1 and the exhaust channel 2 are directional drilling channels drilled from the gasified coal seam floor rock roadway (that is, the ventilated pedestrian roadway 4) towards the coal seam 5, including the rock horizontal section (1- 1, 2-1) and the rock bending section (1-2, 2-2), and the coal seam section in the gasifier. In the coal seam section in the gasifier, the gas injection passage 1 and the exhaust passage 2 are coal seam drilling passages excavated along the coal seam floor, and the excavation direction is fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com