Micro sensor chip and preparation method thereof, gas detection method and application

A gas detection and sensor chip technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of information dispersion, single function, poor portability, etc., to reduce heat dissipation, improve reliability, and easily expand production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] As the preparation method of the above-mentioned gas sensing material, for example, a hydrothermal method, a sol-gel method, and the like can be used. As a hydrothermal method to prepare a gas sensing material, the metal compound can be dissolved into a solution, the obtained solution is stirred and evaporated to dryness to obtain powder, and the gas sensing material is obtained after grinding and sintering.

[0089] As a method of loading the gas-sensitive sensing material on the electrode layer to form a sensing layer, the gas-sensing sensing material can be dissolved in an appropriate solvent and then loaded on the electrode layer by dripping, spraying, etc. Can. Before use, the chip loaded with the gas sensing material is preferably heat-treated, for example, it can be heated at 30-50° C. for 10-15 hours, for example, heated at 40° C. for 12 hours.

[0090] In the present invention, the thickness of the sensing layer is preferably 1-3 μm, more preferably 1.5-2.5 μm...

Embodiment 1

[0123] A micro-sensor chip with 3 micro-sensor modules is prepared by the following method:

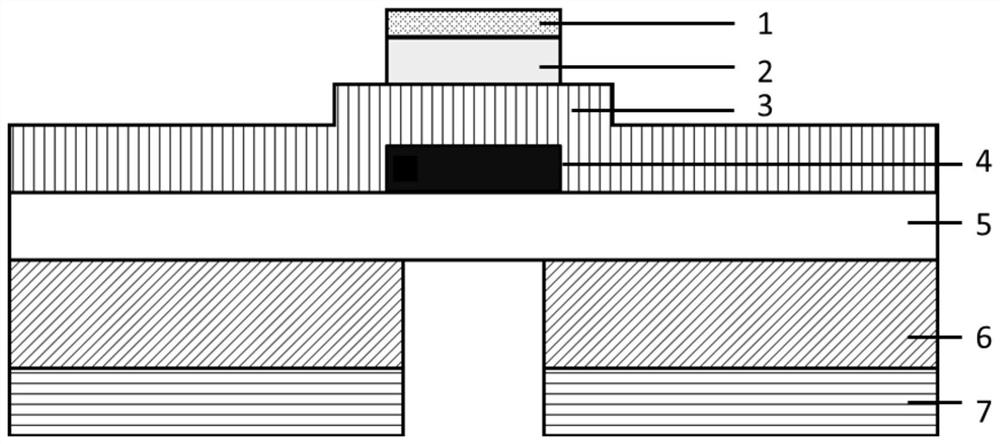

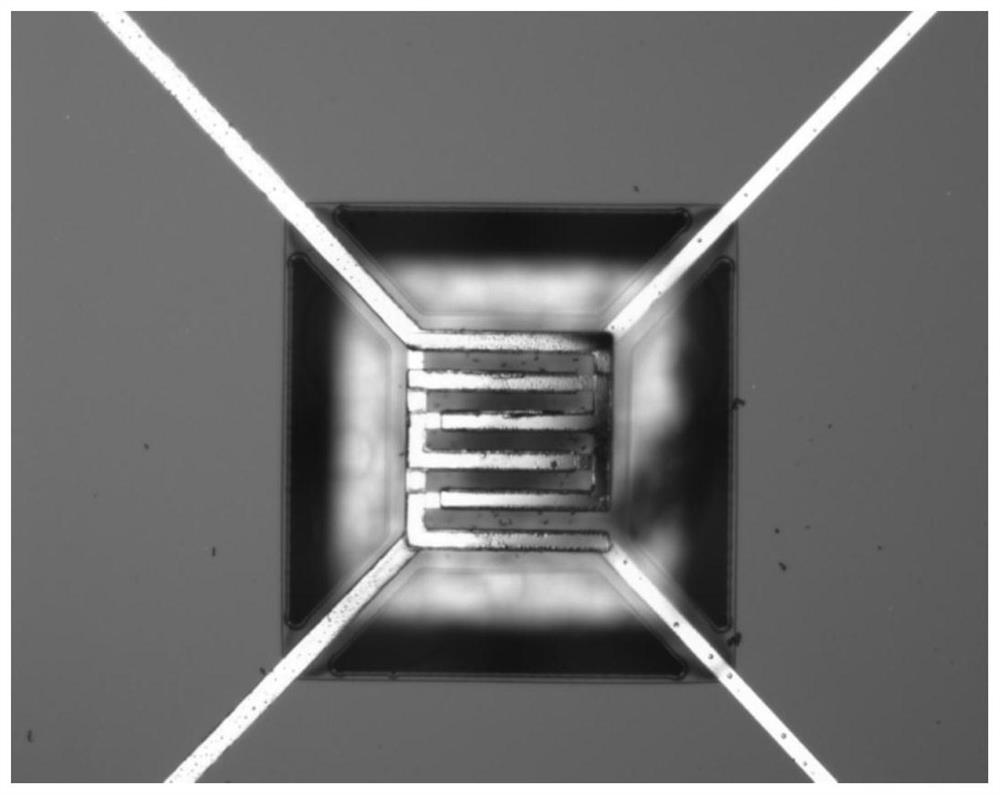

[0124] 1) P-type (100) single crystal silicon wafer with double-sided polishing of 500nm silicon oxide on both sides with a thickness of 500μm (its silicon oxide layer, silicon layer and silicon oxide layer are used as the substrate layer 7, the suspended layer 6 and the support respectively. Layer 5) On the front side, a metal heating wire and a heating electrode connected to the heating wire are prepared as the heating layer 4 by photolithography and vacuum evaporation. Photolithography conditions: use AZ6130 photoresist, exposure time is 8 seconds; vacuum evaporation conditions: vacuum degree is 5 × 10 -7 Below m bar, the vapor deposition rate of Au is 1 A / s, and the vapor deposition rate of Cr is 0.1 A / s. The finally obtained Cr / Au layer of the heating layer (wherein Cr is used as the adhesion layer, with a content of 99.9% by mass) has a thickness of 4 nm; the heating layer 4 in...

Embodiment 2

[0141] Micro-sensing chips were prepared by the method of Example 1, and three kinds of nano-gas-sensing particles prepared by hydrothermal method were respectively loaded on the electrode layers of three micro-sensing modules, and the labels were 1 and 2 respectively. , 3. Wherein, the symbol 1 is the nano-tin oxide particles prepared by the hydrothermal method (the preparation method is carried out according to the nano-tin oxide particles doped with Pd in Example 1, the difference is that Pd is not loaded); the symbol 2 is the nano-oxide prepared by the hydrothermal method Tungsten particles (the preparation method is carried out according to the Pd-doped nano-tin oxide particles in Example 1, the difference is that Pd is not loaded, and WO of the same quality is used 3 instead of SnO 2 ), the symbol 3 is the nano tungsten oxide particles doped with 0.5 mass % palladium prepared by hydrothermal method (the preparation method is carried out according to the nano tin oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com