A Nonpolar Algan-based Schottky UV Detector

A non-polar, detector technology, used in semiconductor devices, electrical components, circuits, etc., can solve the problems of large dark current, lattice mismatch, poor signal-to-noise ratio and stability of ultraviolet detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

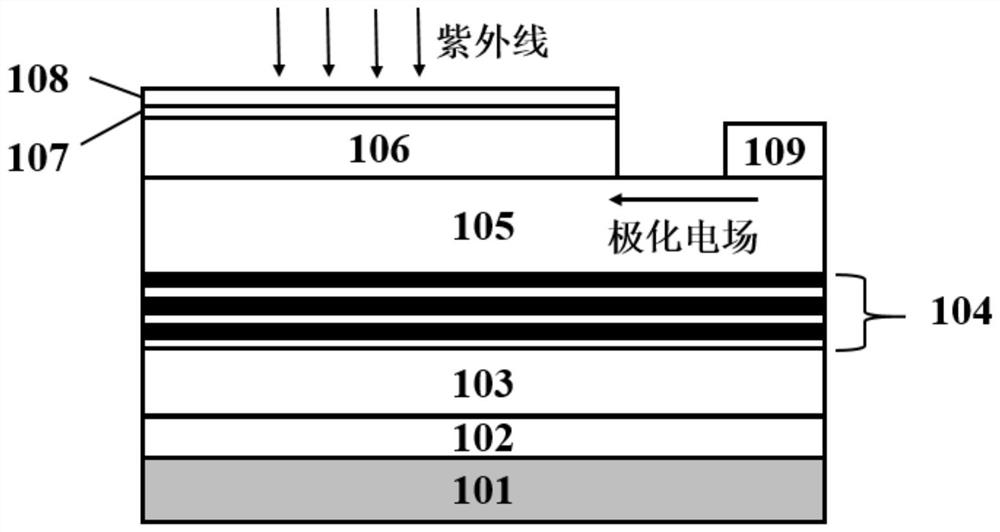

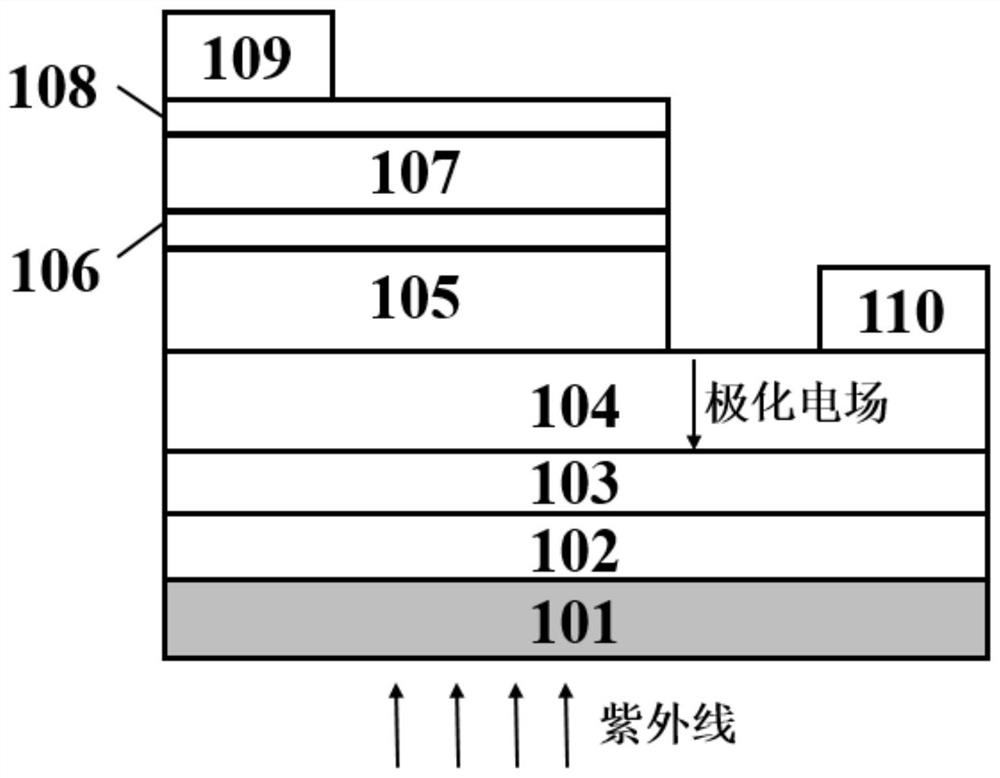

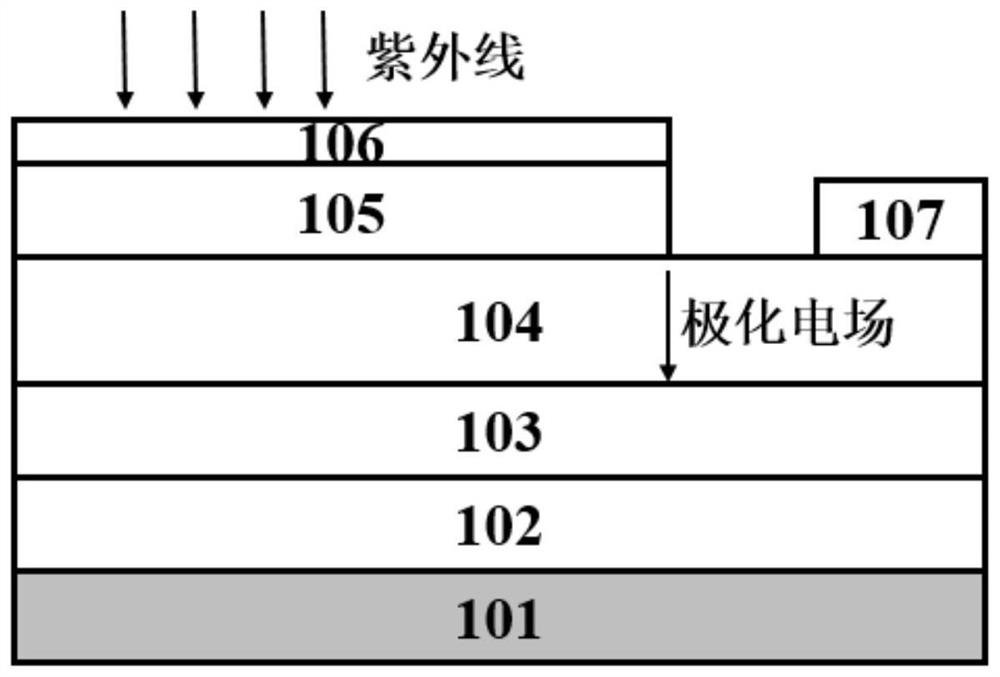

[0018] figure 1 Shown is a non-polar AlGaN-based Schottky ultraviolet detector provided by the present invention, including a substrate (101), a low-temperature AlN nucleation layer (102), and a high-temperature AlN buffer layer (103) arranged in sequence from bottom to top , AlN / Al 0.6 Ga 0.4 N superlattice structure (104), n-type doped n-Al 0.3 Ga 0.7 N layer (105), n-type doped n-Al 0.38 Ga 0.62 N absorption layer (106), AlN barrier enhancement layer (107), metal thin film layer (108), in n-Al 0.3 Ga 0.7 Ohmic electrodes (109) are drawn out from the N layer (105). Except for the substrate (101), metal thin film layer (108) and ohmic electrode (109), all other layers are made of non-polar AlGaN base material.

[0019] The metal thin film layer (108) and the ohmic electrode (109) are respectively located at the negative and positive poles of the transverse polarization electric field.

[0020] The material of the metal thin film layer (108) is Au, and its work funct...

Embodiment 2

[0028] figure 1 Shown is a non-polar AlGaN-based Schottky ultraviolet detector provided by the present invention, including a substrate (101), a low-temperature AlN nucleation layer (102), and a high-temperature AlN buffer layer (103) arranged in sequence from bottom to top , AlN / Al 0.6 Ga 0.4 N superlattice structure (104), n-type doped n-Al 0.3 Ga 0.7 N layer (105), n-type doped n-Al 0.38 Ga 0.62 N absorption layer (106), AlN barrier enhancement layer (107), metal thin film layer (108), in n-Al 0.3 Ga 0.7 Ohmic electrodes (109) are drawn out from the N layer (105). Except for the substrate (101), metal thin film layer (108) and ohmic electrode (109), all other layers are made of non-polar AlGaN base material.

[0029] The metal thin film layer (108) and the ohmic electrode (109) are respectively located at the negative and positive poles of the transverse polarization electric field.

[0030] The material of the metal thin film layer (108) is Au, and its work funct...

Embodiment 3

[0035] figure 1 Shown is a non-polar AlGaN-based Schottky ultraviolet detector provided by the present invention, including a substrate (101), a low-temperature AlN nucleation layer (102), and a high-temperature AlN buffer layer (103) arranged in sequence from bottom to top , AlN / Al 0.6 Ga 0.4 N superlattice structure (104), n-type doped n-Al 0.3 Ga 0.7 N layer (105), n-type doped n-Al 0.38 Ga 0.62 N absorption layer (106), AlN barrier enhancement layer (107), metal thin film layer (108), in n-Al 0.3 Ga 0.7 Ohmic electrodes (109) are drawn out from the N layer (105). Except for the substrate (101), metal thin film layer (108) and ohmic electrode (109), all other layers are made of non-polar AlGaN base material.

[0036] The metal thin film layer (108) and the ohmic electrode (109) are respectively located at the negative and positive poles of the transverse polarization electric field.

[0037] The material of the metal thin film layer (108) is Au, and its work funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com