Biocompatible microphone and preparation method thereof

A microphone and sound bridge technology, applied in the field of biomedical engineering, to achieve the effect of long vibration attenuation, good sealing and long vibration attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

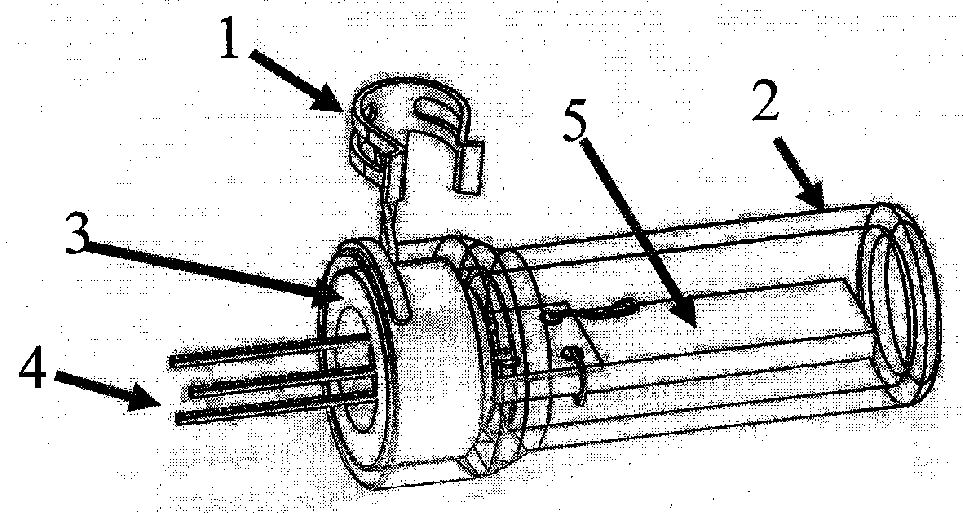

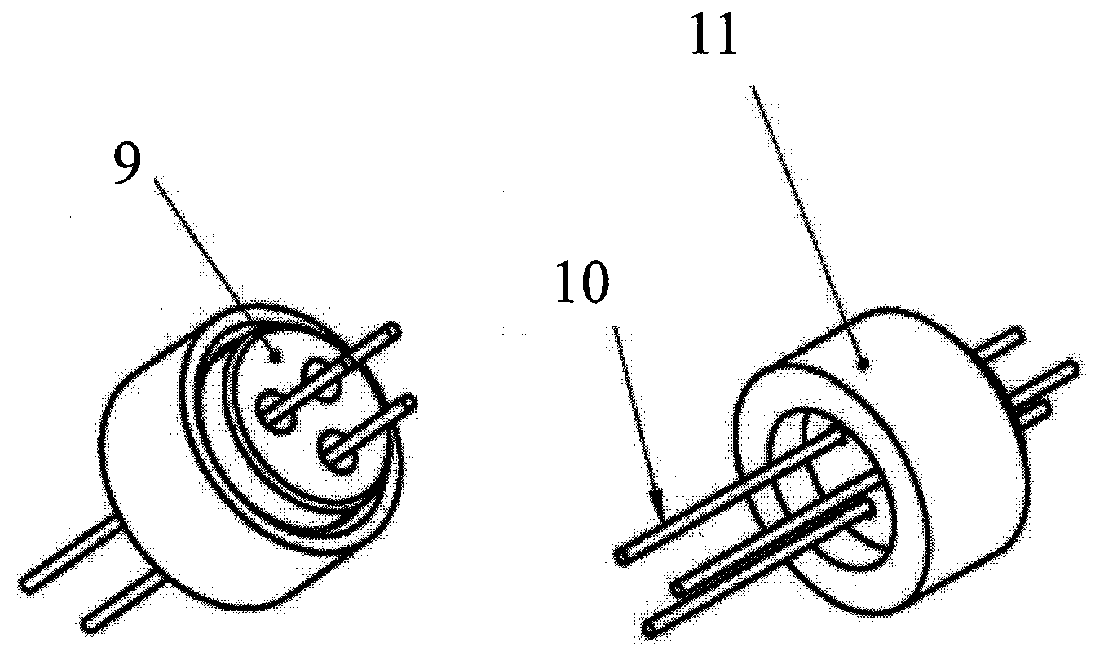

[0039] Example 1 Preparation of a biocompatible piezoelectric ceramic microphone with an acoustic bridge clip structure

[0040] Such as Figure 1~3 as shown,

[0041] 1. Titanium shell production: The titanium shell is a tubular structure with a length of 5.91mm, a rear diameter of 2.02mm, a front diameter of 2.4mm, and a weight of about 40mg. The sound bridge clip is laser welded, which is an extremely thin titanium metal clip with a diameter of 1.38mm. Attaches to the long process of the incus near the stapes;

[0042] 2. Internal connection: Paste and fix the LMV1032 preamplifier system on one end of the piezoelectric ceramic bichip (length 4.0mm) with biological glue;

[0043] Conductive epoxy resin (EPOXY) connects the platinum wire to the terminal of the preamplifier. (The curing temperature of the conductive epoxy resin is ~100°C to 140°C). Two of the platinum wires are directly connected to the terminal, and the remaining two are of appropriate length. A platinum w...

Embodiment 2

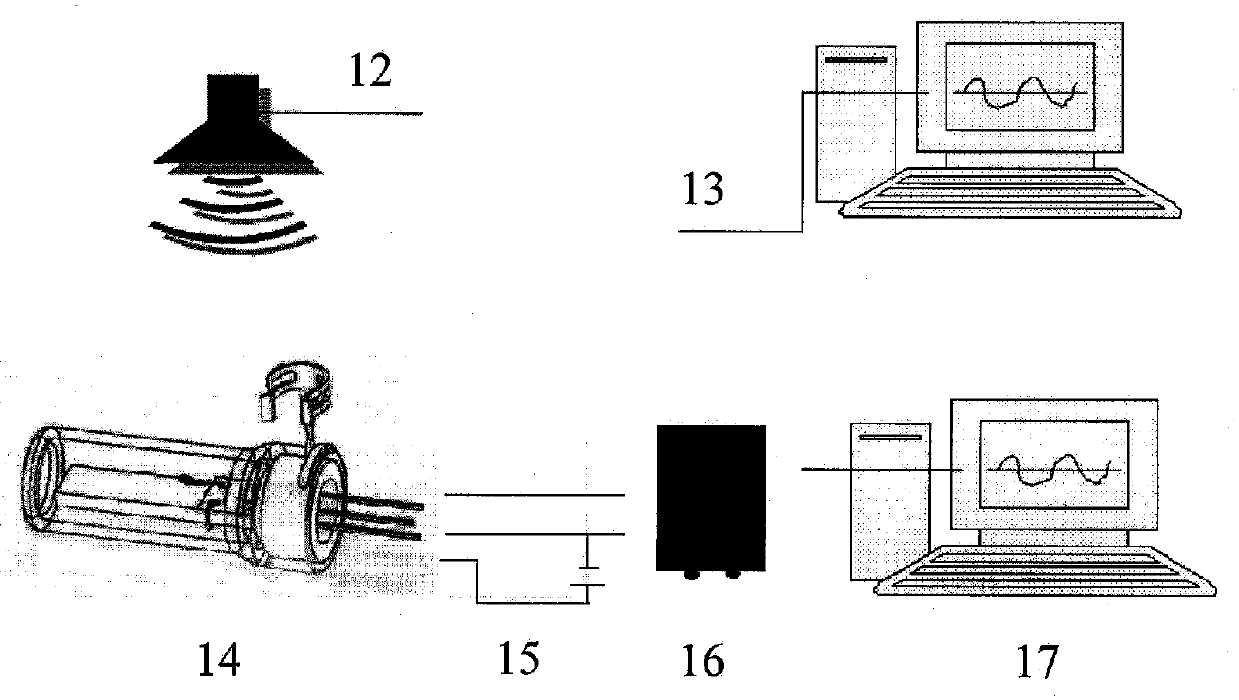

[0045] Example 2 In vitro test experiment

[0046] 1) Experimental equipment RIGOL signal generator, Lenovo notebook computer, YJ56 dual-channel DC power supply, IBM speaker, smart sensor AR814 sound level meter, wire clamp, new piezoelectric microphone (NFPM). All experiments are carried out in a quiet soundproof box (background noise ≤ 30dB SPL);

[0047] 2. In the in vitro experiment, the signal generator outputs the acoustic signal to the speaker, and the new piezoelectric microphone picks up the acoustic signal, converts it into an electrical signal, passes through the NI DAQ9162 data acquisition card, outputs it to the recording computer, and uses NI Lab VIEW SignalExpress software to record it for analysis Calculate and compare the amplitude of the frequency response main peak and the frequency response curve of each group;

[0048] 3. The standard test sound emitted by the signal generator in vitro is output through the above-mentioned high-fidelity speaker as the sou...

Embodiment 3

[0055] Example 3 In vivo (fresh temporal bone) experiment of NFPM

[0056] 1. Experimental equipment: ELAC speaker, MARANTZ power amplifier, RIGOL signal generator, AR814 sound level meter, YJ56 dual-channel DC power supply, ear microsurgical instruments and microscope, all experiments are carried out in a quiet soundproof box ( Background noise ≤20 dB SPL);

[0057] 2. Temporal bone: 3 sets of fresh temporal bone specimens, 5 ears in total (2 left ear, 3 right ear), all donated by the Shanghai Red Cross Society, all donated specimens have a body donation certificate;

[0058] 3. Test method: ① Tympanoplasty was performed through a retroauricular incision, and the operation method was a posterior tympanic approach to expose the long process of the incus and the anvil-stirrup joint. The integrity of the bone wall and skin of the external auditory canal is preserved (complete wall type), and all ligaments of the ossicular chain are preserved during the operation, so as to ensur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com