Method and system for hydrogen production through ethyl alcohol

A technology for producing hydrogen from ethanol and anhydrous ethanol, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve problems that are difficult and have not received enough attention, and achieve simple operation, easy storage and transportation, and high product returns Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention is not limited to the embodiments described below. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other, and the technical idea of the present invention can be combined with other known technologies or other technologies that are the same as those known technologies implement.

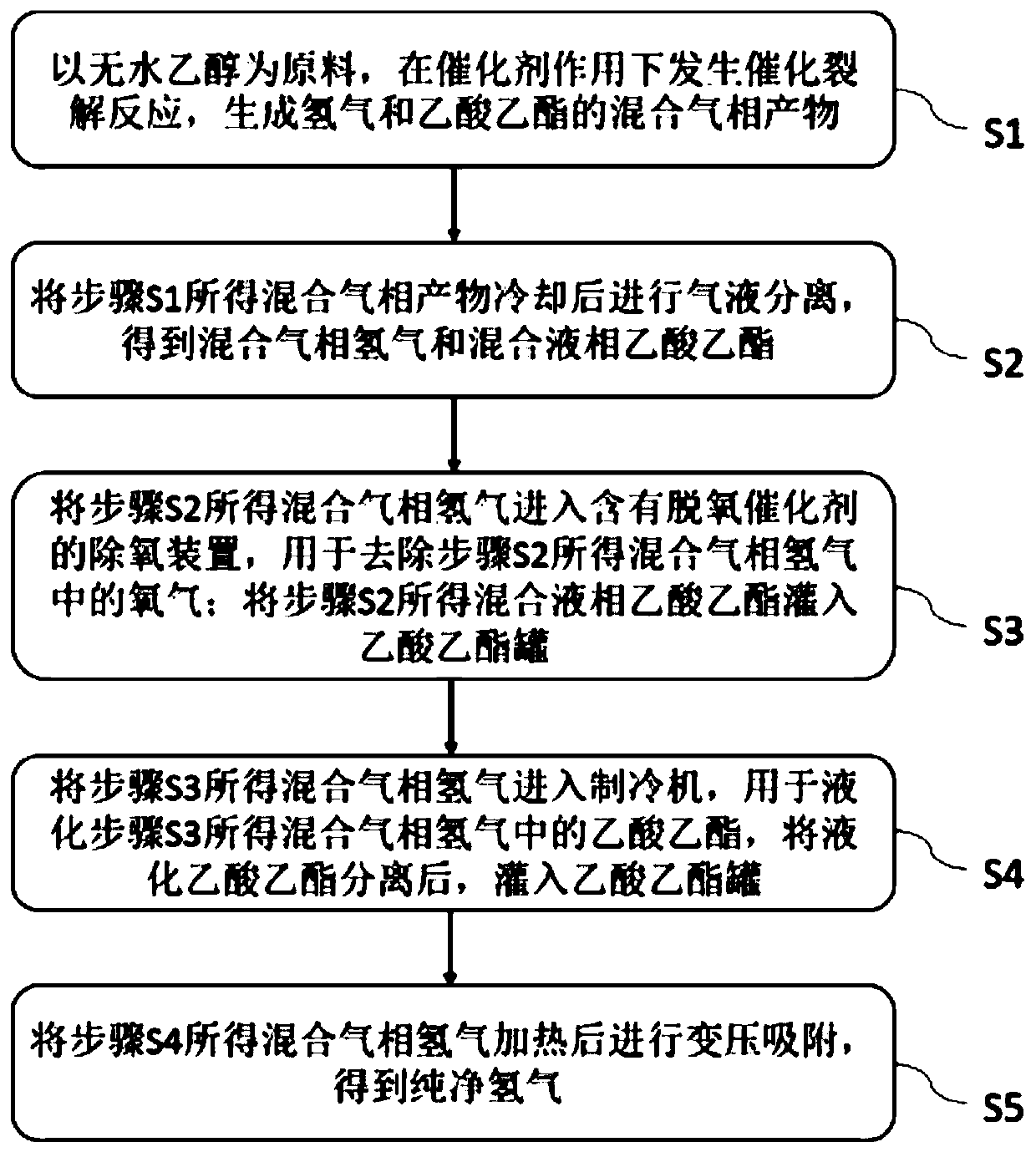

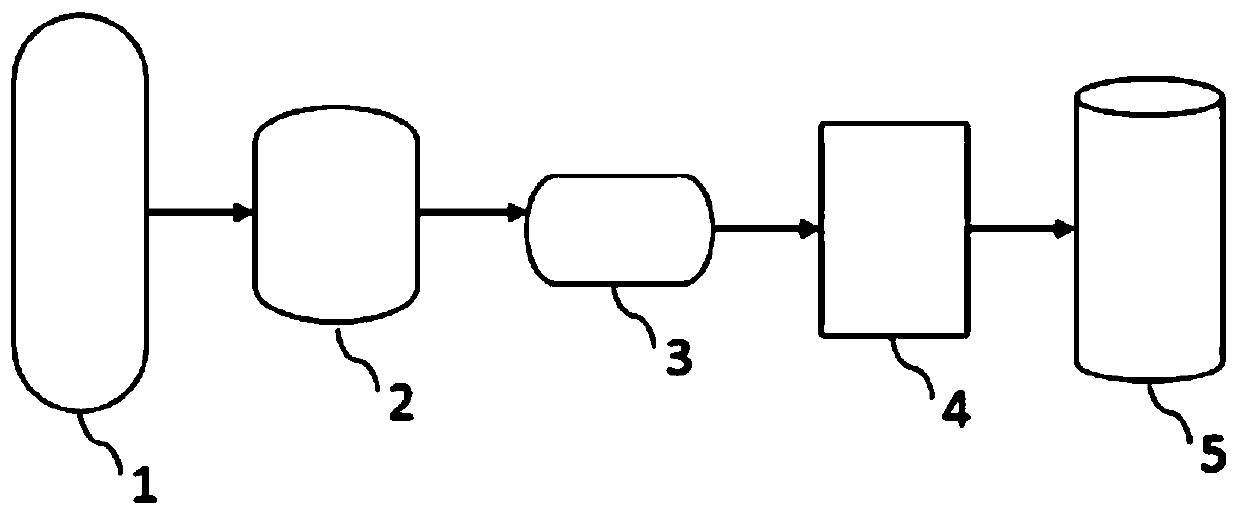

[0036] refer to figure 1 As shown, a method for ethanol catalytic hydrogen production provided in this embodiment includes the following steps:

[0037] Step S1: Using absolute ethanol as a raw material, a catalytic cracking reaction occurs under the action of a catalyst to generate a mixed gas phase product of hydrogen and ethyl acetate, wherein the catalyst can be a Cu-Zn-Al catalytic system, Cu-Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com