Technology for preparing metamizole magnesium through one-pot method

A kind of technology of analgin magnesium and process, applied in the field of medicine, can solve the problems of high price of ion exchange resin, unstable product quality, unstable magnesium analgin, etc., and achieve the effects of stable process, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

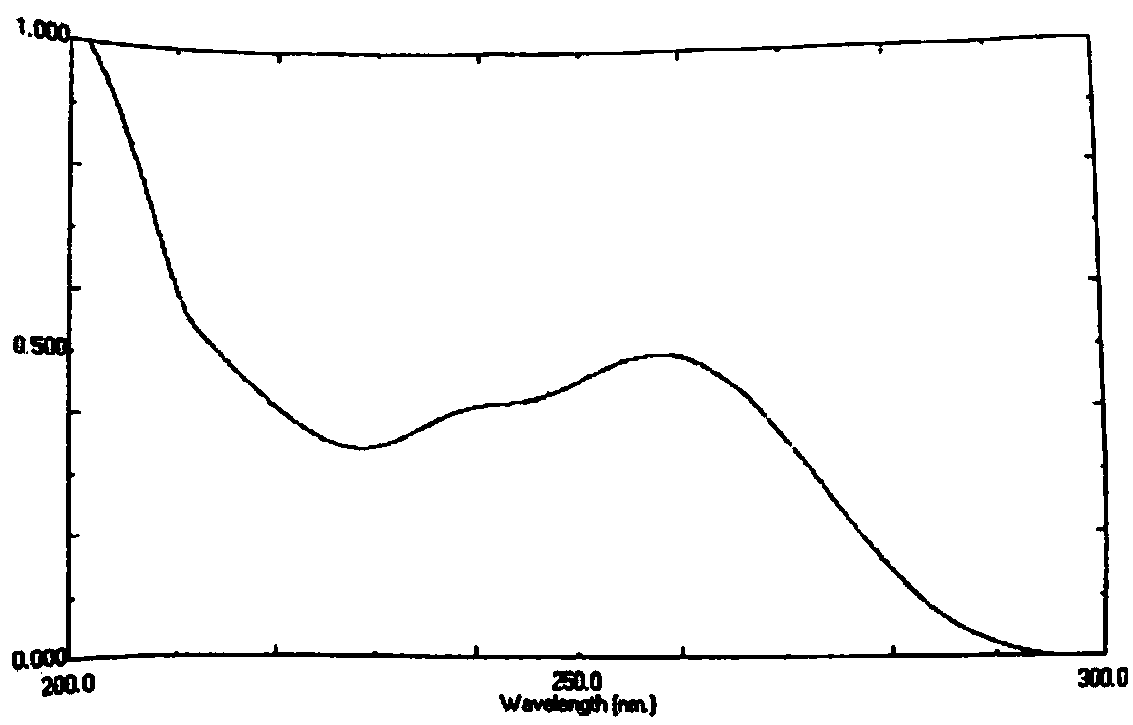

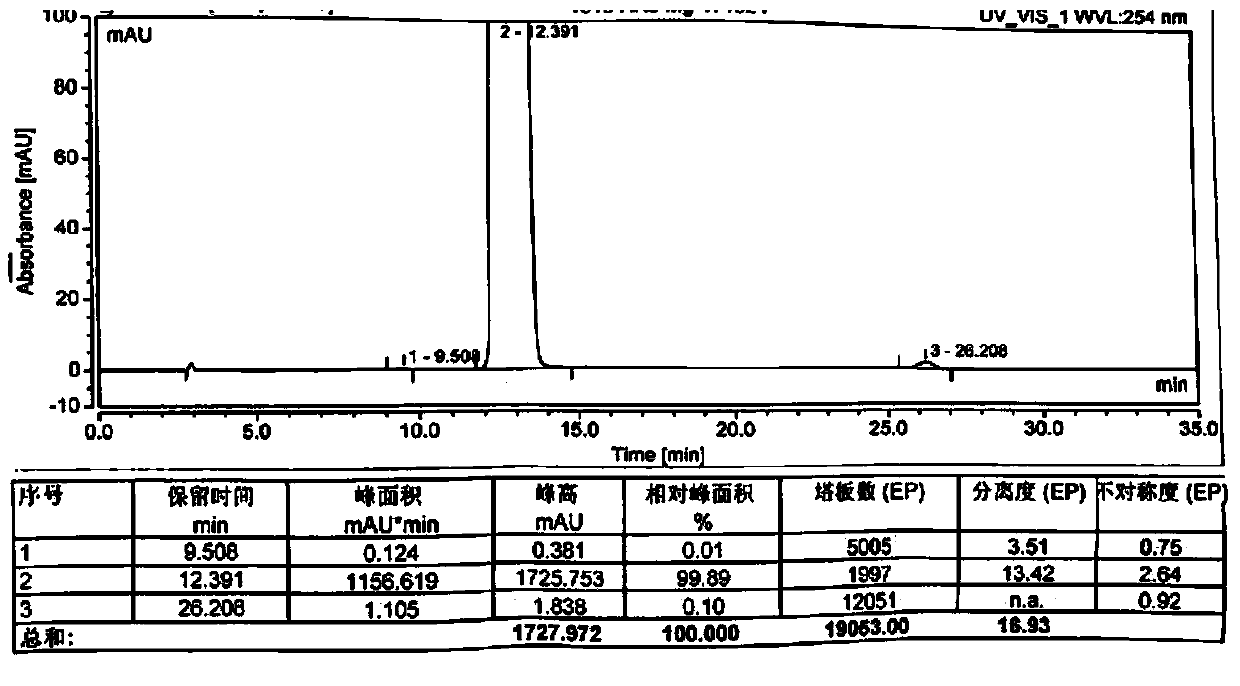

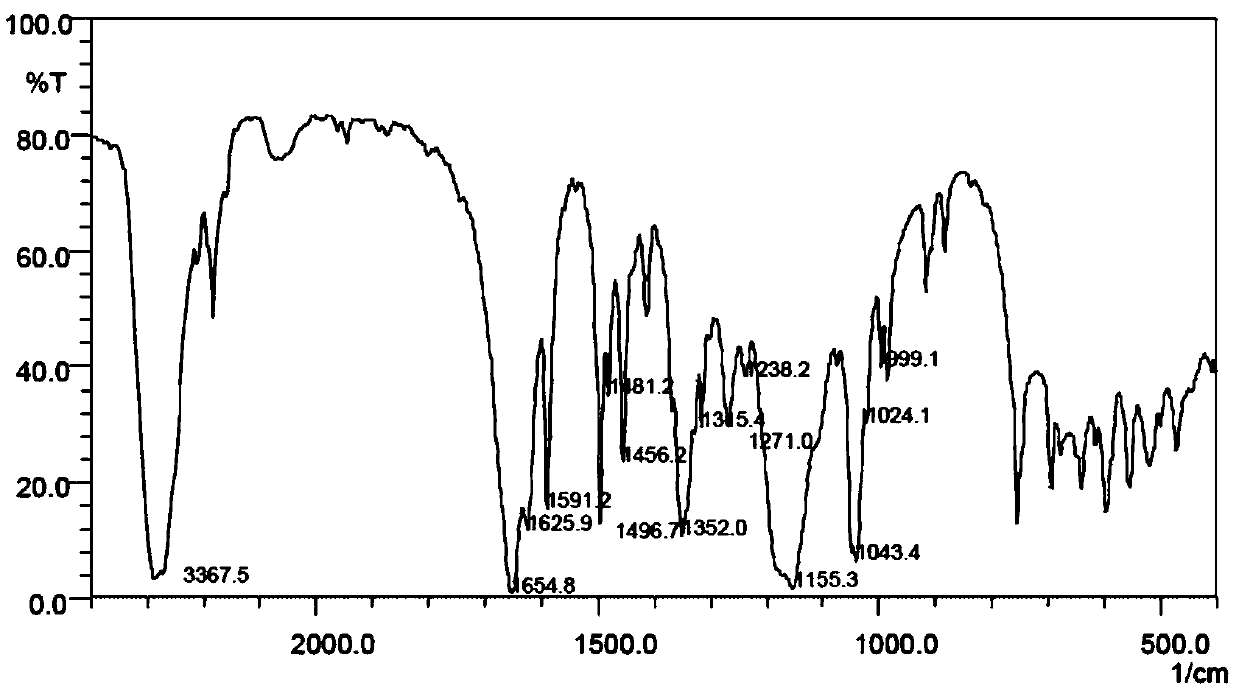

Image

Examples

Embodiment 1

[0050] Add compound 4-methylaminoantipyrine (MAA) (217.3g, 1mol), MgO (40.3g, 1mol) formaldehyde solution (110g, mass fraction 36%) and 550ml methanol into a 1L reaction flask, 20-30 Stir at ℃ to disperse the system, slowly introduce SO 2gas, the reaction temperature is 30-80°C, and the end point of the reaction is judged by PH test paper in the later stage of aeration. And keep stirring at 20~50℃ for 1h. Lower the temperature of the reaction system to 0-25°C, heat and crystallize for 2 hours, then filter with suction, rinse the filter cake with a small amount of ice isopropanol, and dry it by blasting to obtain 350.2 g of analgin magnesium (ANJ-Mg), with a yield of 93% .

Embodiment 2

[0052] Compound MMA (217.3g, 1mol), MgO (40.3g, 1mol), formaldehyde solution (110g, mass fraction 36%) and 550ml isopropanol are added in the 1L reaction flask, and lead to sulfur dioxide in the reaction flask, the reaction temperature The temperature is 30-80° C., and the purity of MAA in the reaction system monitored by HPLC is less than or equal to 0.5%, which means the end of the reaction is judged. The reaction solution was cooled to 0-5°C in an ice-water bath and kept warm for crystallization for 2 hours, filtered with suction, washed the filter cake with a small amount of ice isopropanol, and dried by blasting to obtain 354.0 g of analgin magnesium, with a yield of 94%.

Embodiment 3

[0054] The compound MMA (217.3g, 1mol), MgO (40.3g, 1mol), formaldehyde solution (110g, mass fraction 36%) and 550ml of ethanol were added to a 1L reaction flask, and sulfur dioxide was introduced into the reaction flask, and the pressure was increased to the reaction flask. The internal pressure of the bottle is 40-60psi, and it is heated to 40-80°C to react. If the pressure of the reaction bottle drops, continue to pass sulfur dioxide to maintain the internal pressure of the reaction bottle at 20-50 psi. React until the internal pressure of the reaction bottle remains basically unchanged within 0.5 to 1 hour, then cool down to room temperature, cool the reaction solution to 0 to 5°C in an ice-water bath and keep it warm for crystallization for 2 hours, filter with suction, rinse the filter cake with a small amount of ice ethanol, and After air-drying, 338.9 g of analgin magnesium was obtained, with a yield of 90%.

[0055] Table 1: Effect of solvent type and dosage on the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com