3, 3'-diamino-4, 4'-oxazafurazan multi-stage geode and preparation method thereof

A technology of azofurazan oxide and diamino, which is applied in organic chemistry methods, offensive equipment, organic chemistry, etc., can solve the problems that DAAF self-assembled crystal multi-level structure has not been reported, and achieves mild experimental conditions and good safety , The effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

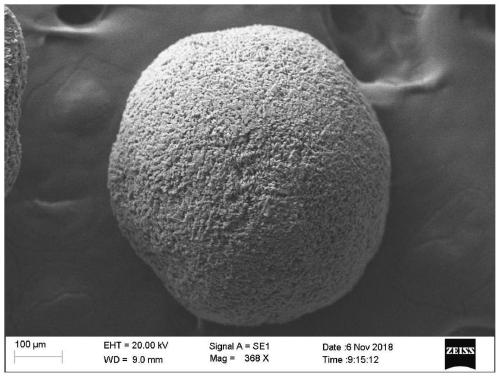

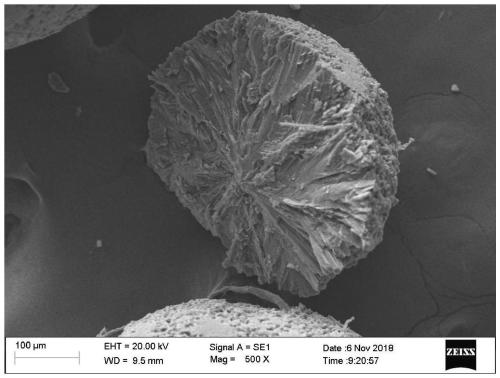

[0023] Weigh 0.3 g of 3,3’-diamino-4,4’-azofurazan and 20 mL of dimethyl sulfoxide at room temperature, stir and place the beaker in an ultrasonic oscillator until completely dissolved. Put the beaker in a constant temperature incubator, set the temperature at 30°C, and slowly evaporate the solvent. After the solvent is completely evaporated, filter it under reduced pressure, and rinse it with ultrapure water and absolute ethanol to wash away the residual solvent in the explosive. . Vacuum-dried for 3-4 hours to obtain 3,3'-diamino-4,4'-azofurazan multi-level crystal balls. figure 1 and figure 2 They are the scanning electron micrographs and the cross-sectional electron micrographs of the 3,3'-diamino-4,4'-azoxide multi-level structure explosive obtained according to this example, respectively. The size of the microspheres is 300 μm to 450 μm, the size of the small nanoparticles constituting the microspheres is 10 μm to 20 μm, and the product purity is 99.6%. When dimethyl...

Embodiment 2

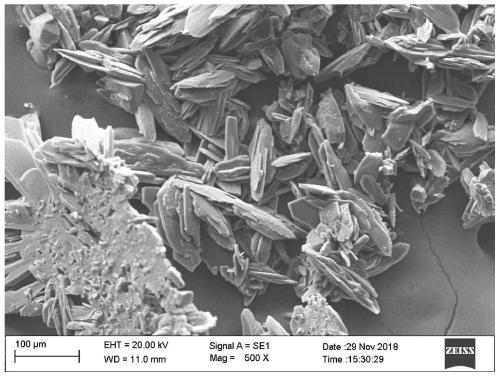

[0025] Weigh 0.3g of 3,3'-diamino-4,4'-azofurazan at room temperature, measure 30mL of acetone, stir and place the beaker in an ultrasonic oscillator until completely dissolved. Put the beaker in a constant temperature incubator, set the temperature at 30°C, and slowly evaporate the solvent. After the solvent is completely evaporated, filter it under reduced pressure, and rinse it with ultrapure water and absolute ethanol to wash away the residual solvent in the explosive. . Vacuum-dried for 3-4 hours to obtain 3,3'-diamino-4,4'-azofuroxan. image 3 It is a scanning electron micrograph of the 3,3'-diamino-4,4'-azoxyl explosive obtained according to this example. The product is a strip crystal with a length of about 100 μm, and the product purity is 99.0%. Acetone has a low polarity (5.4), and will generate intermolecular forces with the secondary growth crystal planes, and the growth rate of this plane is inhibited, resulting in the rapid growth of the main growth crystal pl...

Embodiment 3

[0027] Weigh 0.3g of 3,3'-diamino-4,4'-azofurazan and 45mL of ethyl acetate at room temperature, stir and place the beaker in an ultrasonic oscillator until completely dissolved. Put the beaker in a constant temperature incubator, set the temperature at 30°C, and slowly evaporate the solvent. After the solvent is completely evaporated, filter it under reduced pressure, and rinse it with ultrapure water and absolute ethanol to wash away the residual solvent in the explosive. . Vacuum-dried for 3-4 hours to obtain 3,3'-diamino-4,4'-azofurazan multi-level crystal balls. figure 1 and figure 2 They are the scanning electron micrographs and the cross-sectional electron micrographs of the 3,3'-diamino-4,4'-azoxide multi-level structure explosive obtained according to this embodiment, respectively. The product is massive broken crystals with a wide range of particle size distribution, about 10 μm to 100 μm, and the product purity is 99.4%. Ethyl acetate is less polar (4.3), and wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com