A new type of waste heat recycling system and method at cold end of power plant

A cold end and waste heat technology of a power plant, applied in steam application, machine operation mode, machines using waste heat, etc., can solve the problems of low waste heat utilization rate, environmental pollution, energy waste, etc., and achieve high waste heat utilization rate and environmental protection Effects of pollution and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

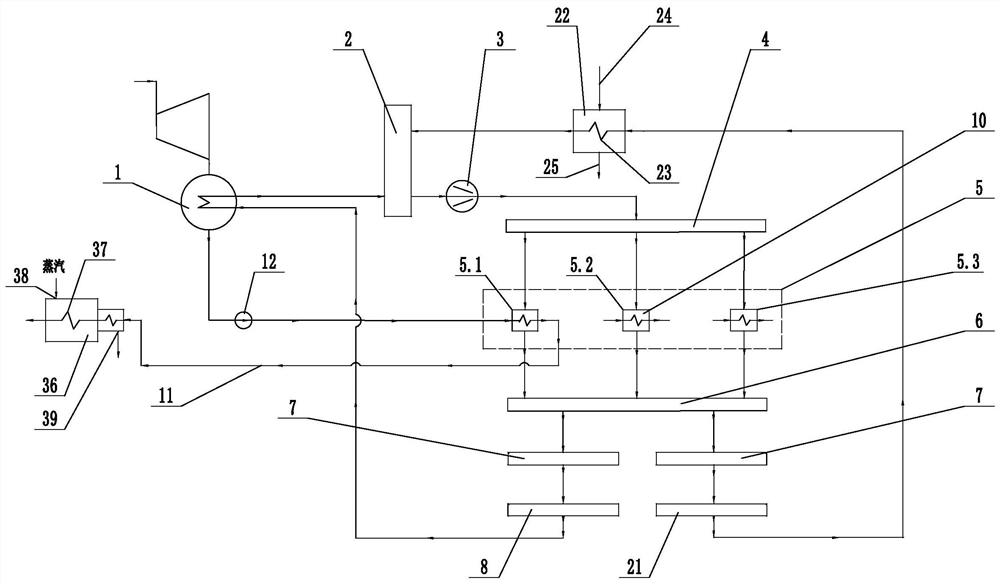

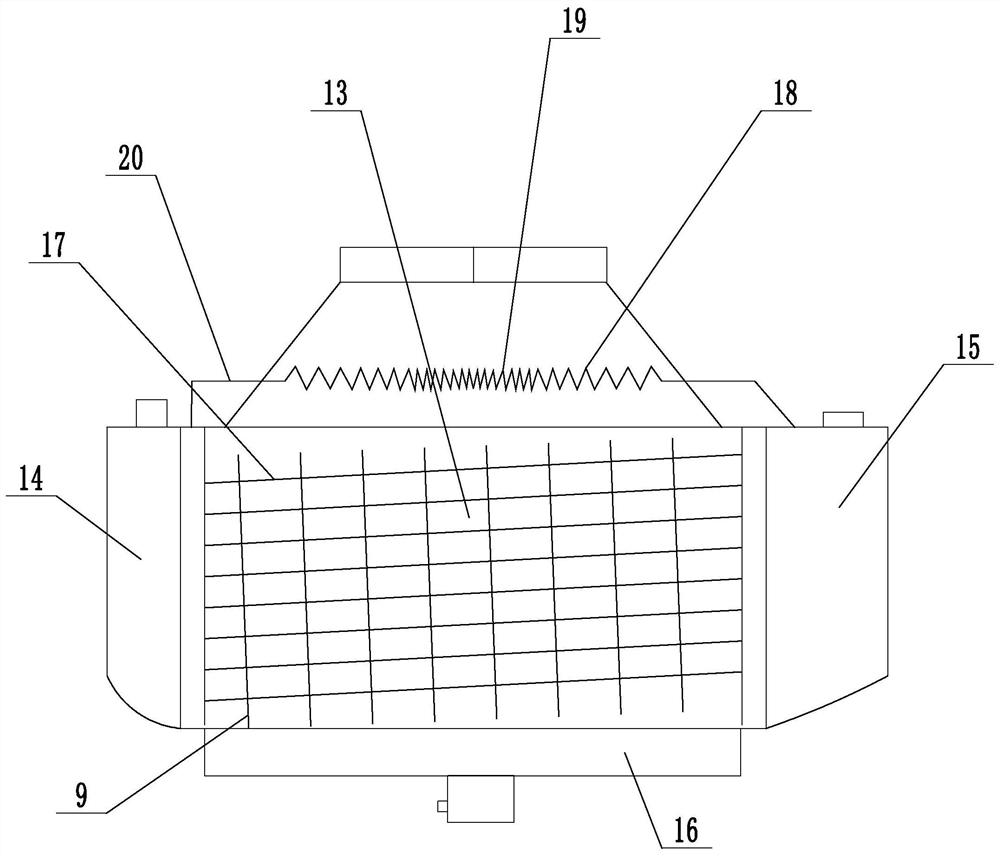

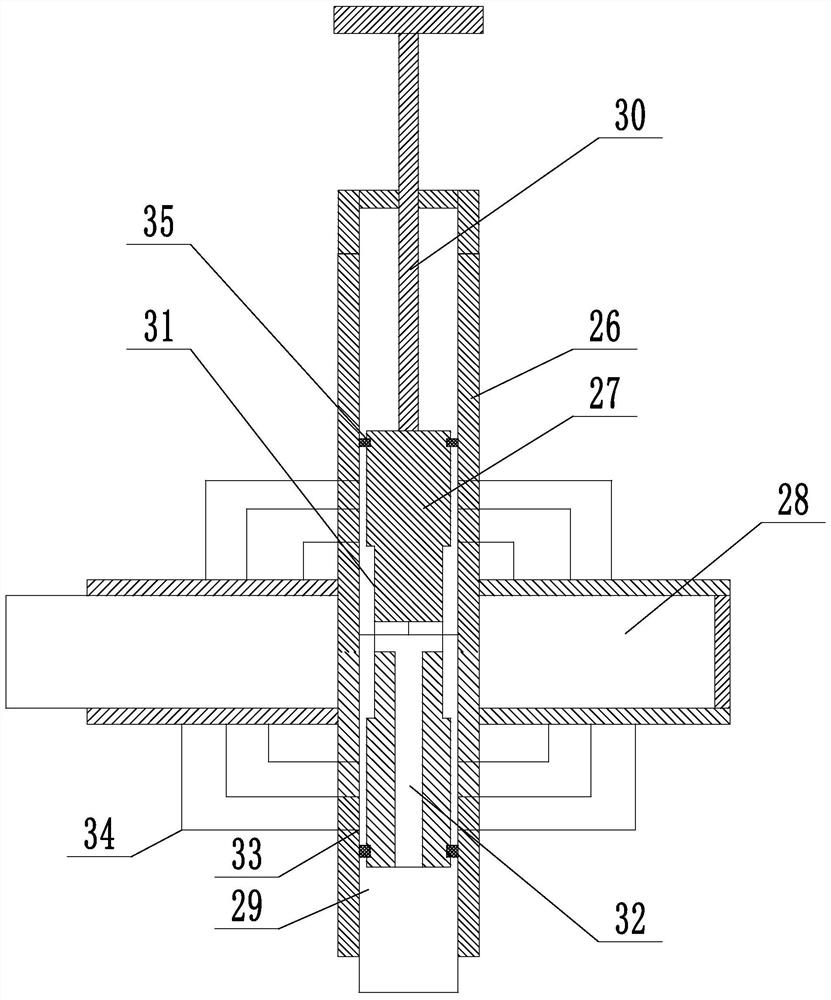

[0019] Example: A new type of waste heat recycling system at the cold end of a power plant (see attached figure 1 to attach image 3 ), including the main evaporator condenser 1, the gaseous refrigerant receiving header 2 after absorbing heat and evaporation, the refrigeration compressor unit 3, the compressed high-temperature and high-pressure gaseous refrigerant receiving header 4, several heat exchangers 5, and the liquid refrigerant receiving header Box 6, liquid refrigerant throttling valve group 7, mainstream refrigerant pressure stabilizing header 8; refrigerant evaporation tube 9 is installed in the main evaporation condenser, and one end of the refrigerant evaporation tube is connected to the gaseous refrigerant receiving header after heat absorption and evaporation The other end is connected with the mainstream refrigerant pressure stabilizing header. There is a refrigerant condensation chamber 10 in the heat exchanger. The refrigerant condensation chamber is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com