Improved method for manufacturing lithium ion battery electrode

A lithium-ion battery and electrode technology, applied in battery electrodes, electrode manufacturing, electrode rolling/calendering, etc., can solve the problems of excessive material consumption, slowness, low redox reaction, etc., and achieve a simple, practical and effective operation process. High, the effect of eliminating electrode polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

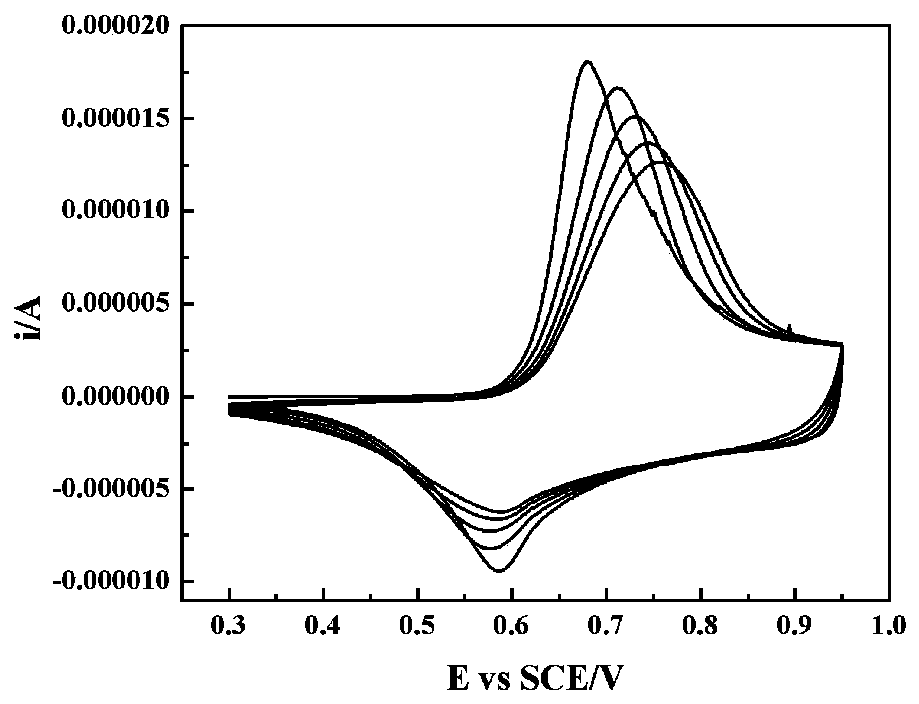

Image

Examples

Embodiment 1

[0033] I. The preparation of the MTI-LCO electrode active complex that improved method makes:

[0034] Dispersion of S1, PTFE: Take by weighing 0.0445g PTFE dispersion emulsion, 20ml dehydrated alcohol respectively, put PTFE dispersion emulsion in the beaker first, then drop dehydrated alcohol into the beaker that PTFE dispersion emulsion is housed with dropper, simultaneously , Shake the beaker to make the absolute ethanol break the PTFE dispersion emulsion, seal the mouth of the beaker with plastic wrap, and disperse by ultrasonic for 35 minutes. In order to prevent the water temperature in the ultrasonic machine from overheating, change the water every 15 minutes until the solution in the beaker is evenly dispersed And when no obvious milky white aggregates or precipitation can be observed, the dispersion of PTFE is complete;

[0035] S2. Mixing slurry: put the PTFE dispersed in step S1 together with the beaker into a magnetic stirrer and stir, and at the same time add 0.20...

Embodiment 2

[0046] I. The preparation of the MTI-LCO electrode active compound that general method makes:

[0047] Dispersion of S1, PTFE: Take by weighing 0.0445g PTFE dispersion emulsion, 20ml dehydrated alcohol respectively, put PTFE dispersion emulsion in the beaker first, then drop dehydrated alcohol into the beaker that PTFE dispersion emulsion is housed with dropper, simultaneously , Shake the beaker to make the absolute ethanol break the PTFE dispersion emulsion, seal the mouth of the beaker with plastic wrap, and disperse by ultrasonic for 35 minutes. In order to prevent the water temperature in the ultrasonic machine from overheating, change the water every 15 minutes until the solution in the beaker is evenly dispersed And when no obvious milky white aggregates or precipitation can be observed, the dispersion of PTFE is complete;

[0048] S2. Mixing slurry: put the PTFE dispersed in step S1 together with the beaker into a magnetic stirrer and stir, and at the same time add 0.20...

Embodiment 3

[0056] I. The preparation of the OCT-LMO electrode active compound that general method makes:

[0057] S1 is consistent with the step S1 of the preparation method of the MTI-LCO electrode active composite made by the general method in Example 2

[0058] S2, mixing slurry: put the PTFE dispersed in step S1 together with the beaker into a magnetic stirrer to stir, and at the same time add 0.36994g of homemade octahedral LiMn to the beaker one by one 2 o 4 (GuanhuaJin, HangQiao, HualinXie, HaiyanWang, KejianHe, PingLiu, JiajieChen, YougenTang, SuqinLiu, ChenghuanHuang, Synthesis of single-crystalline octahedral LiMn 2 o 4 as high performance cathode for Li-ion battery, Electrochimica Acta, Volume 150, 20December 2014, Pages 1-7), 0.04005 acetylene black, then seal the beaker with plastic wrap, and keep stirring overnight to obtain a slurry;

[0059] S3-S5 are consistent with steps S3-S5 of the preparation method of the MTI-LCO electrode active composite produced by the general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com