Novel absorbent for benzene-series volatile organic compounds (VOCs) and preparation method and application of absorbent

An organic compound and volatile technology, which is applied in the field of new benzene-based volatile organic compound absorbent and its preparation, can solve the problems of high price, pollution, and easy volatility, and achieve high solubility, selectivity, and good biodegradability , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

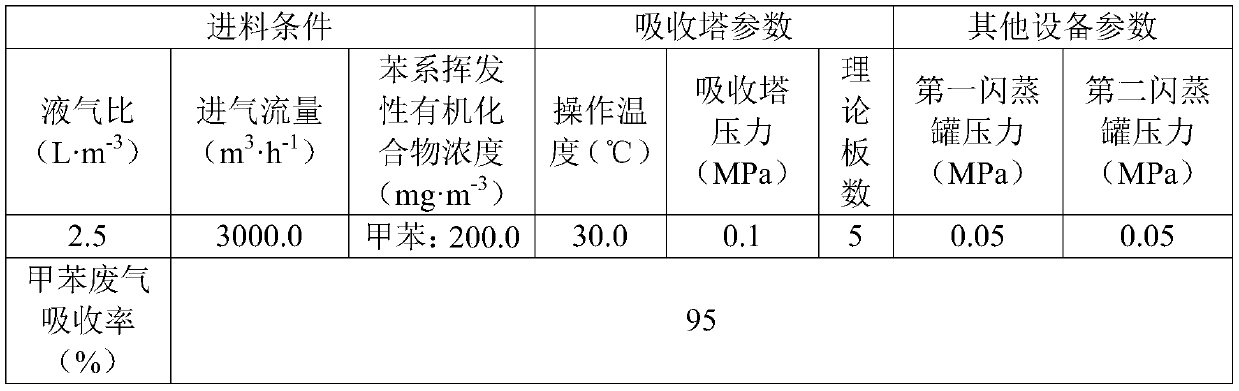

Embodiment 1

[0025] A benzene series volatile organic compound absorbent, the molar ratio of hydrogen bond donor oleic acid to hydrogen bond acceptor tetraethylammonium chloride is 2:1. The preparation method is as follows: Weigh the corresponding mass of hydrogen bond donor oleic acid and the corresponding mass of hydrogen bond acceptor tetraethylammonium chloride in a container, and heat the container at a heating temperature of 70°C. While heating, start the stirring device to stir the liquid mixture. After a clear and transparent liquid is formed in the container, stop heating and continue stirring. After the temperature of the solution in the container cools down to room temperature, stop stirring.

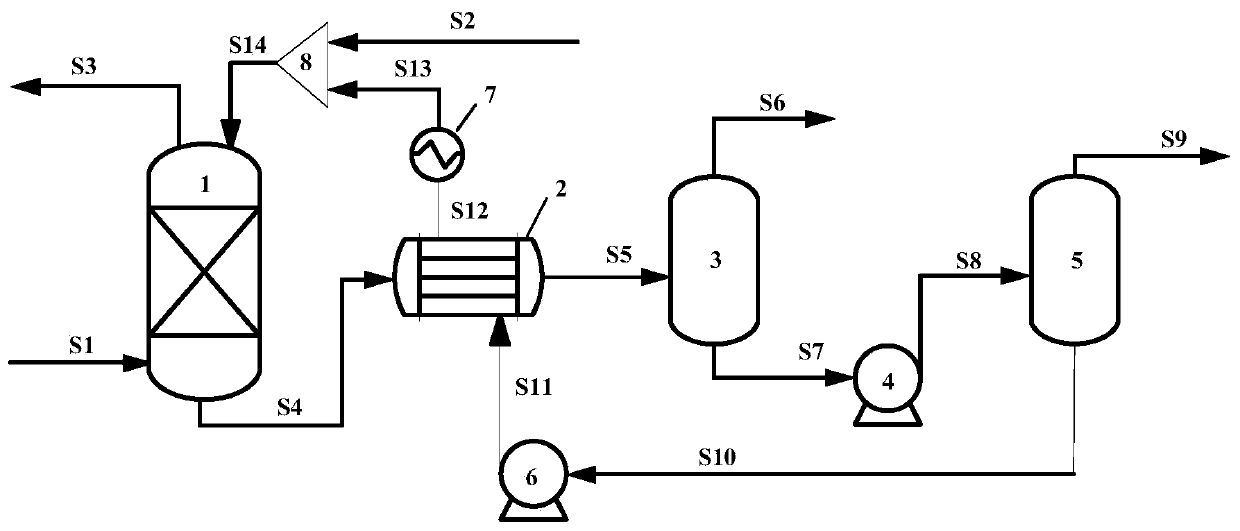

[0026] Such as figure 1 As shown, embodiment 1 also proposes the device of applying described novel benzene series VOC absorbent, comprising: absorption tower 1, heat exchanger 2, first flash tank 3, second flash tank 5, Cooler 7 and mixer 8; the absorption tower 1 communicates with the ...

Embodiment 2

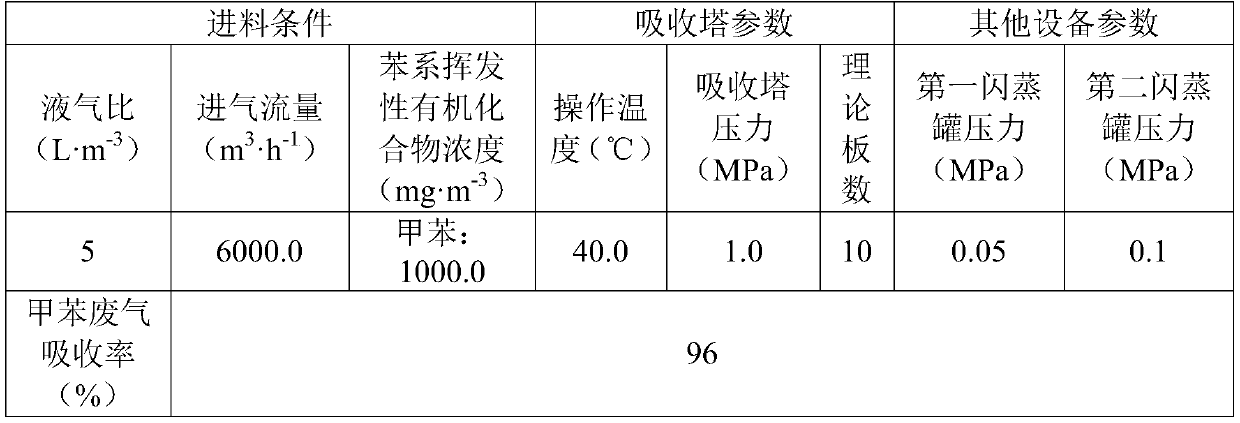

[0031] A benzene series volatile organic compound absorbent, the molar ratio of hydrogen bond donor oleic acid to hydrogen bond acceptor tetraethylammonium chloride is 3:1. The preparation method is as follows: Weigh the corresponding mass of hydrogen bond donor oleic acid and the corresponding mass of hydrogen bond acceptor tetraethylammonium chloride in a container, and heat the container at a heating temperature of 90°C. While heating, start the stirring device to stir the liquid mixture. After a clear and transparent liquid is formed in the container, stop heating and continue stirring. After the temperature of the solution in the container cools down to room temperature, stop stirring.

[0032] use as figure 1 As shown in the process, the stream S1 containing toluene waste gas enters the absorption tower 1 from the bottom of the tower, and the absorbent S14 is sprayed down from the top of the tower, and the sprayed absorbent and toluene waste gas undergo material exchange...

Embodiment 3

[0035] A benzene series volatile organic compound absorbent, the molar ratio of hydrogen bond donor oleic acid to hydrogen bond acceptor tetraethylammonium chloride is 5:1. The preparation method is as follows: Weigh the corresponding mass of hydrogen bond donor oleic acid and the corresponding mass of hydrogen bond acceptor tetraethylammonium chloride in a container, and heat the container at a heating temperature of 120 ° C. While heating, start the stirring device to stir the liquid mixture. After the clear and transparent liquid is formed in the container, stop heating and continue stirring. After the temperature of the solution in the container cools down to room temperature, stop stirring.

[0036] use as figure 1 As shown in the process, the stream S1 containing toluene waste gas enters the absorption tower 1 from the bottom of the tower, and the absorbent S14 is sprayed down from the top of the tower, and the sprayed absorbent and toluene waste gas undergo material exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com