A method for preparing self-doped sulfur fluorescent carbon nano-dots using lignosulfonate

A technology of lignosulfonate and carbon nano-dots, which is applied in nanotechnology, nano-carbon, and nano-technology for materials and surface science, and can solve the problems of limited raw material sources of fluorescent carbon nano-dots and large pollution of strong acid catalysts. , to achieve the effect of green environmental protection, safety, non-toxic price and good industrialization prospect of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

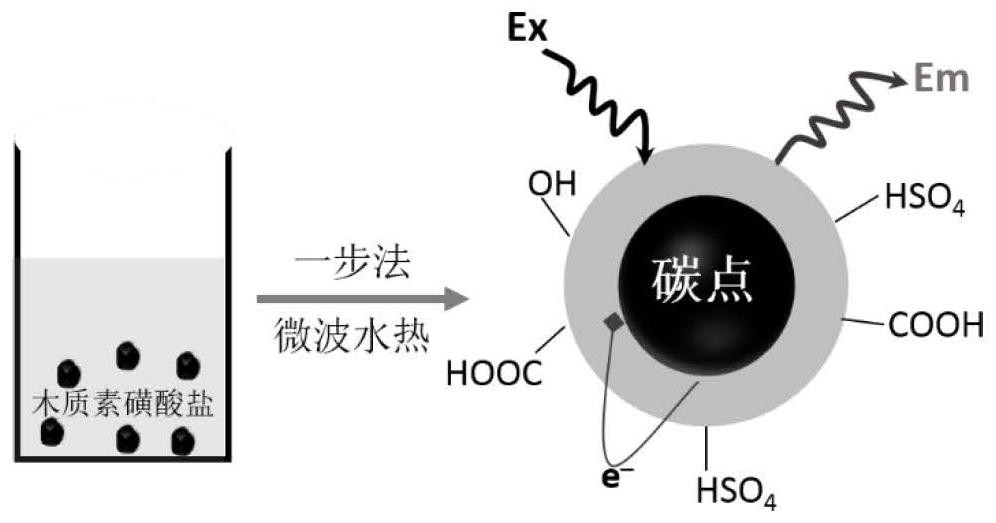

[0037] figure 1 It is a flow chart prepared by the present invention. The preparation method of the present invention comprises the following steps:

[0038] (1) Mix lignosulfonate and water uniformly at a solid-to-liquid ratio of 1:20 (g / mL), and the amount of ionic liquid 1-butyl-3-methylimidazolium acetylsulfonate ([bmim]Ace) to 3 μL, transferred to a microwave reactor, heated to 180°C by microwave, and reacted for 3 hours to obtain a black turbid liquid;

[0039] (2) The black turbid liquid is centrifuged with a high-speed centrifuge at a speed of 10,000 rpm to remove the black precipitate, and then filtered with a 2 μm water filter membrane to obtain a filtrate containing carbon nanodots;

[0040] (3) Freeze-dry the clarified filtrate of step (2) at -50° C. to powder to obtain in-situ sulfur-doped carbon nanodots with a yield of 13.1%.

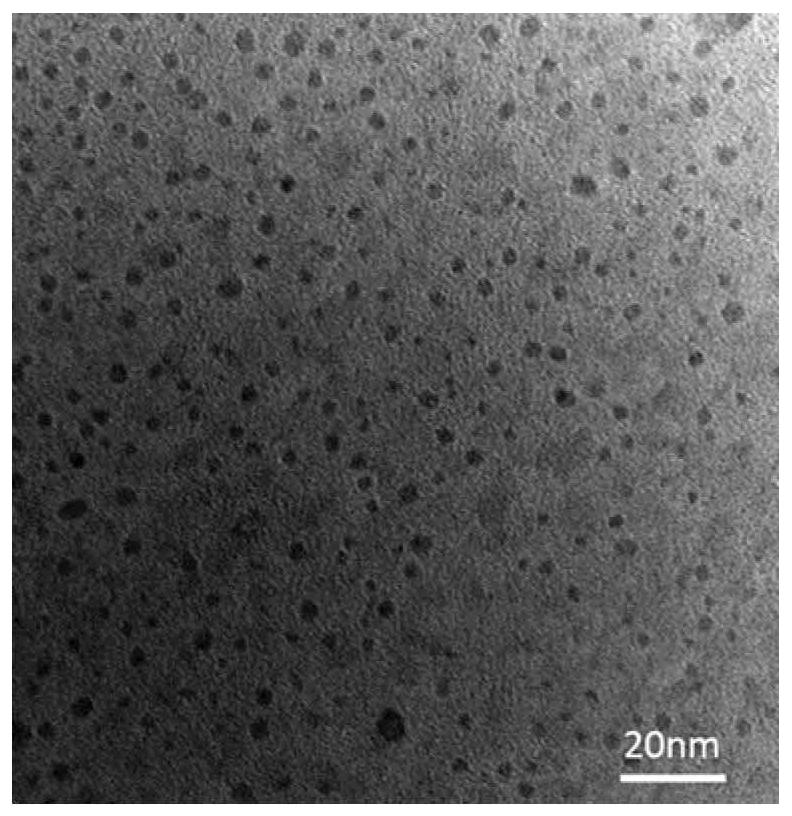

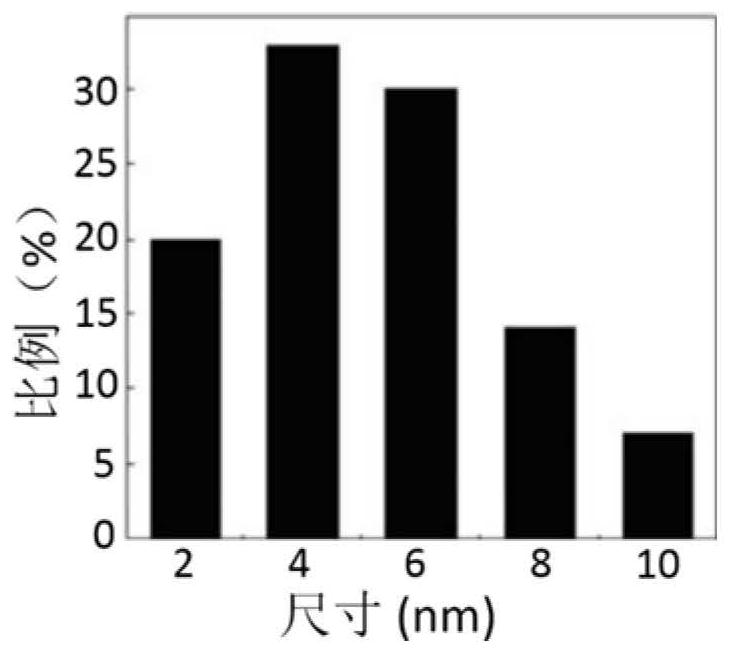

[0041] figure 2 It is the carbon nano-dot scanning electron micrograph (SEM) prepared in embodiment 1. Depend on figure 1 It can be...

Embodiment 2

[0047] (1) Mix lignosulfonate and water uniformly at a solid-to-liquid ratio of 1:10 (g / mL), and the amount of ionic liquid 1-butyl-3-methylimidazolium acetylsulfonate ([bmim]Ace) 1 μL, transferred to a microwave reactor, heated to 140°C by microwave, and reacted for 0.5h to obtain a black turbid liquid;

[0048] (2) The black turbid liquid is centrifuged with a high-speed centrifuge at a speed of 10,000 rpm to remove the black precipitate, and then filtered with a 2 μm water filter membrane to obtain a filtrate containing carbon nanodots;

[0049] (3) Freeze-dry the clarified filtrate of step (2) at -50° C. to powder to obtain in-situ sulfur-doped carbon nanodots with a yield of 3.4%.

Embodiment 3

[0051] (1) Mix lignosulfonate and water uniformly at a solid-to-liquid ratio of 1:30 (g / mL), and the amount of ionic liquid 1-butyl-3-methylimidazolium acetylsulfonate ([bmim]Ace) to 5 μL, transferred to a microwave reactor, heated to 200°C by microwave, and reacted for 4 hours to obtain a black turbid liquid;

[0052] (2) The black turbid liquid is centrifuged with a high-speed centrifuge at a speed of 10,000 rpm to remove the black precipitate, and then filtered with a 2 μm water filter membrane to obtain a filtrate containing carbon nanodots;

[0053] (3) Freeze-dry the clarified filtrate of step (2) at -50° C. to powder to obtain in-situ sulfur-doped carbon nanodots with a yield of 12.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com