A photocatalytic reaction device and process for treating rose bengal b high-salt wastewater

A photocatalytic reaction and high-salt wastewater technology, applied in the direction of physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of light stability and insufficient photocatalytic performance, and achieve high use value and applicable The effect of wide range and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

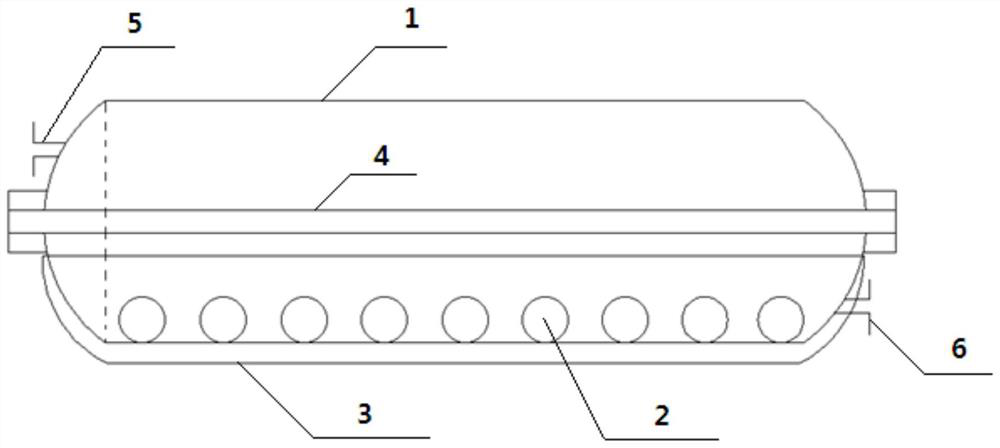

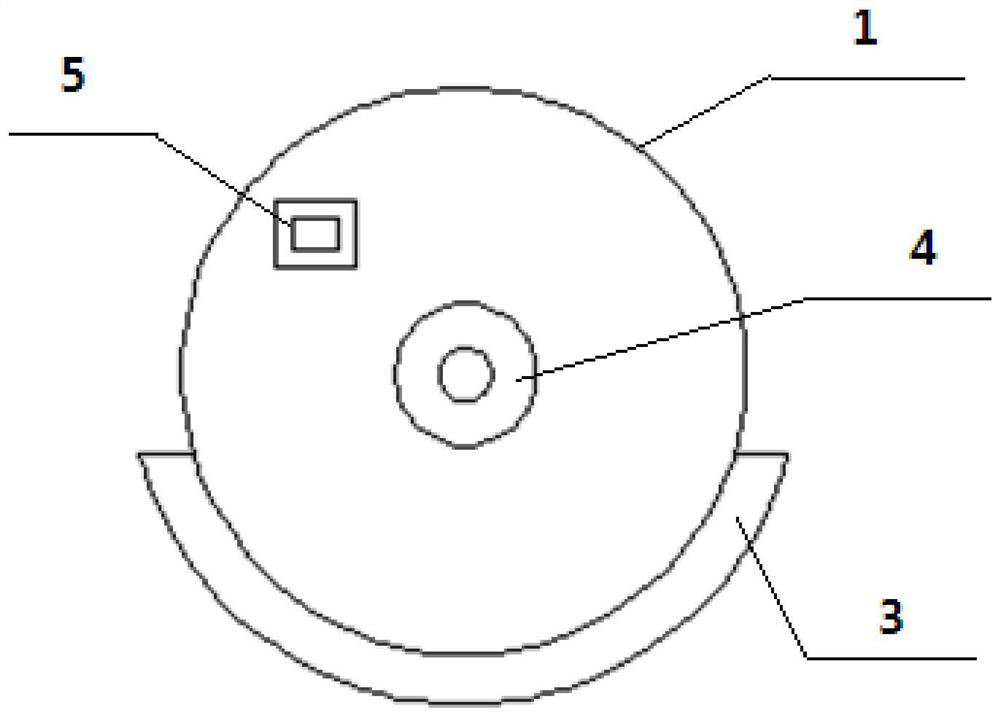

[0053] Such as figure 1 and figure 2 As shown, a photocatalytic reaction device for treating Rose Bengal B high-salt wastewater includes a transparent casing 1, an aerator 2 is arranged inside the transparent casing 1, and a light-concentrating film 3 is arranged under the aerator 2 for aeration. A transparent casing 4 equipped with a light source is also arranged above the device 2 .

[0054] In this embodiment, the transparent casing 1 is made of transparent material, wherein the transparent material is polymethyl methacrylate, which has good light transmission and strong plasticity.

[0055] In this embodiment, the aerator 2 is a miniature aerator, installed at a distance of 5 cm from the lowest point of the transparent shell 1, the aeration hole of the aerator 2 faces the lowest point of the transparent shell 1, and the installation method is a cross installation. The spacing is 16cm. In this embodiment, a micro-aerator is arranged in the transparent housing 1, and the...

Embodiment 2

[0060] A photocatalytic reaction device for treating Rose Bengal B high-salt wastewater includes a transparent casing 1, an aerator 2 is arranged inside the transparent casing 1, and a light-concentrating film 3 is arranged below the aerator 2.

[0061] In this embodiment, the transparent casing 1 is made of transparent material, wherein the transparent material is polymethyl methacrylate, which has good light transmission and strong plasticity.

[0062] In this embodiment, the aerator 2 is installed at a distance of 5 cm from the lowest point of the transparent shell 1, and the aeration hole of the aerator 2 faces the lowest point of the transparent shell 1, and the installation method is cross installation, and the installation distance is 20 cm. In this embodiment, an aerator 2 is arranged in the transparent housing 1, and the photocatalytic material can be fully contacted with the reaction system (waste water) by continuously blowing air during use, so that the photocatalyt...

Embodiment 3

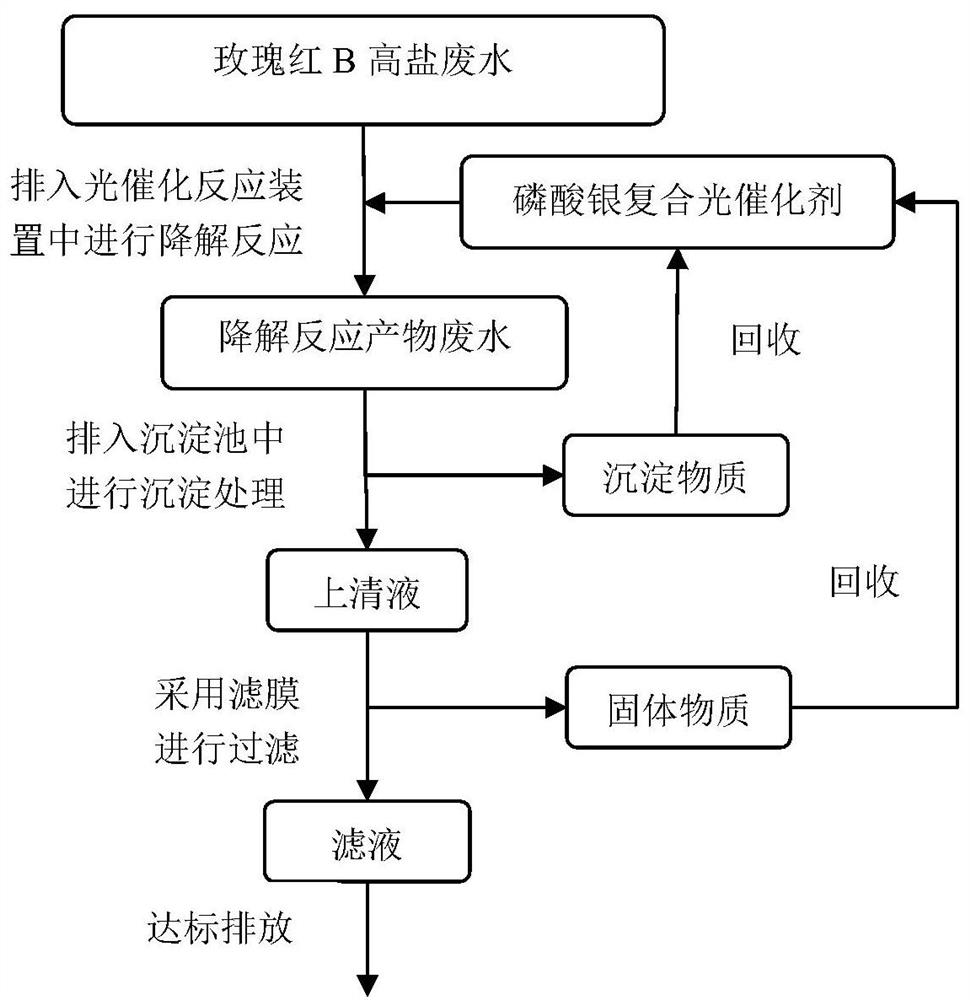

[0065] A process for treating Rose Bengal B high-salt wastewater, specifically using the photocatalytic reaction device in Example 2 to treat Rose Bengal B high-salt wastewater, and its process flow chart is as follows image 3 shown, including the following steps:

[0066] S1, the Na 2 SO 4The mass percentage content 1%, 5%, 12%, 18%, 21% rose bengal B high-salt waste water (volume is 40L, and the concentration of rose bengal B is 20mg / L) is added to the photocatalysis of embodiment 2 respectively In the reaction device, add 10g of silver phosphate composite photocatalyst, stir in the dark for 30min to make it mix evenly and reach the adsorption-desorption equilibrium, carry out the degradation reaction under sunlight for 10min, at the same time, turn on the photocatalytic reaction device Aerator for aeration.

[0067] S2, after the degradation reaction of step S1 is completed, the wastewater in the photocatalytic reaction device is added to the sedimentation tank (convent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com