Polymer coating material for early-warning of metal corrosion and preparation method of polymer coating material

A polymer coating, metal corrosion technology, applied in coatings, luminescent coatings, etc., can solve the problems of low corrosion detection sensitivity and no change, and achieve the effect of avoiding poor compatibility, avoiding corrosion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

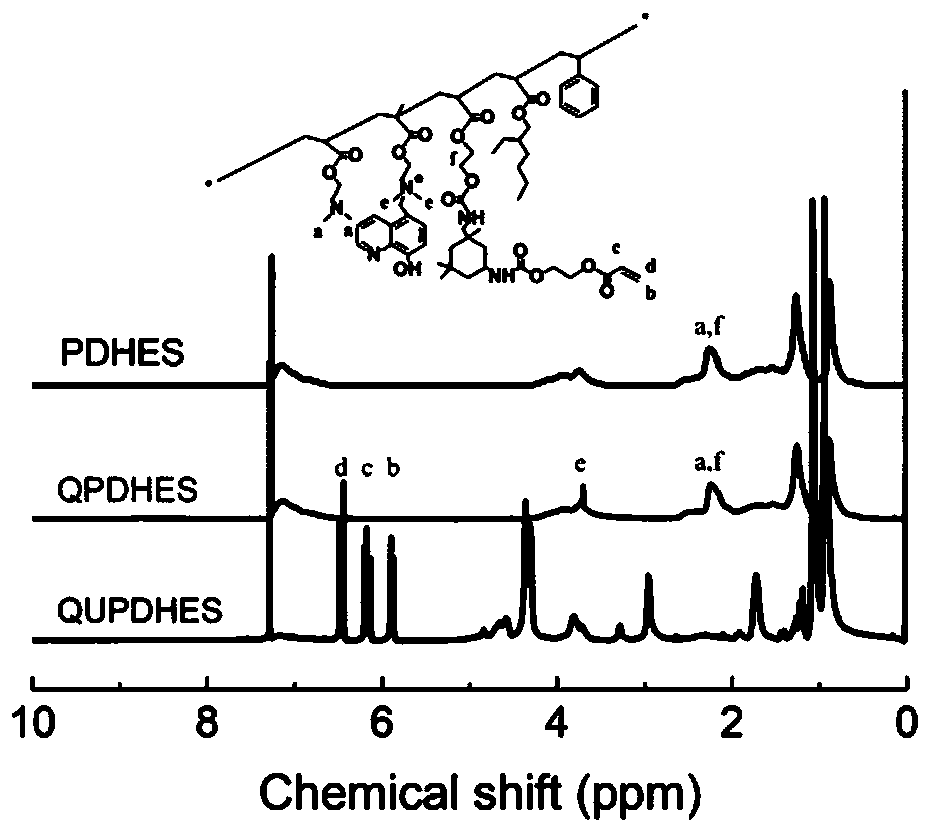

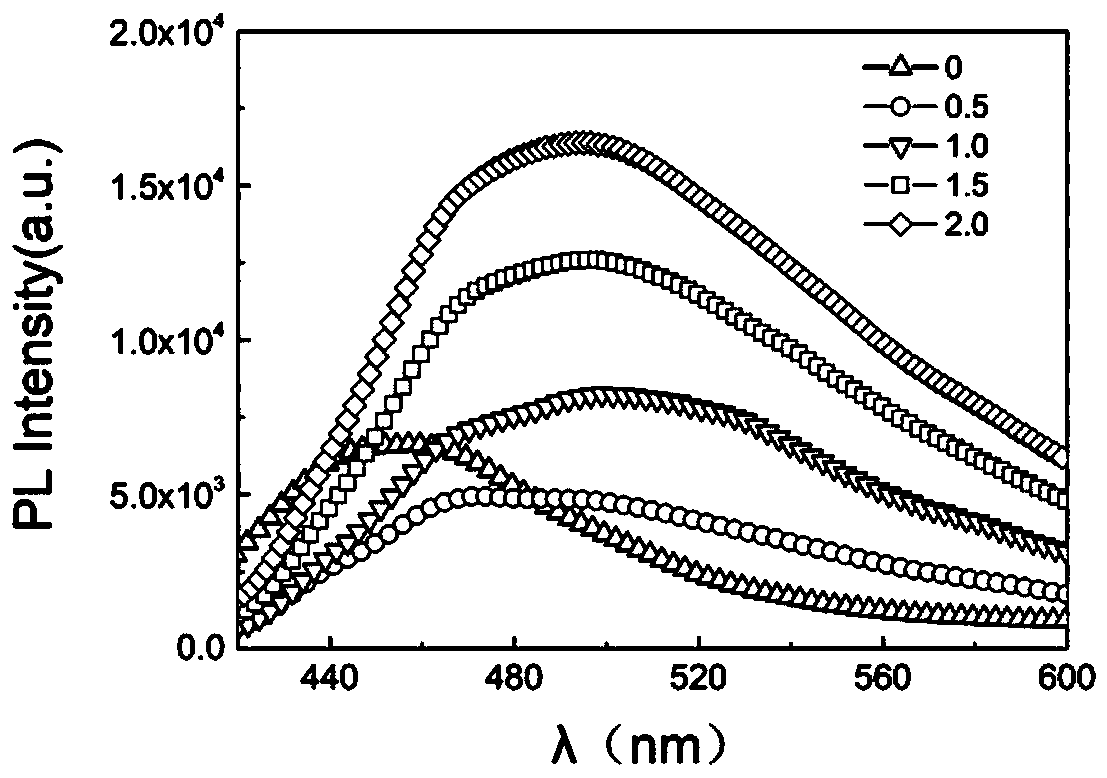

[0035](1) Synthesis of copolymer: Weigh 4.71g (30mmol) dimethylaminoethyl methacrylate (DMAEMA), 5.82g (58mmol) styrene (St), 11.80g (64mmol) isooctyl acrylate (EHA) , 4.64g (40mmol) of hydroxyethyl acrylate (HEA) was dissolved in 80mL of ethyl acetate, and then 0.886g of initiator azobisisobutyronitrile was added, deoxygenated by nitrogen gas for 30min, and reacted at 80°C for 24h. After the reaction was completed, most of the solvent was removed by rotary evaporation, diluted with tetrahydrofuran (THF), and repeatedly precipitated with petroleum ether to obtain the copolymer PDHES.

[0036] (2) Dissolve the copolymer PDHES16g in 80mL N,N-dimethylformamide (DMF), and then add 1.03g (5.3mmol) 5-chloromethyl-8-hydroxyquinoline (CHQ) to the solution, 0.5g sodium iodide was used as a catalyst, 3g potassium carbonate was used as an acid-binding agent, the reaction was carried out at 80°C for 24h, and the quaternized polymer QPDHES was obtained by repeated precipitation in ether. ...

Embodiment 2

[0040] (1) Synthesis of copolymer: Weigh 4.71g (30mmol) dimethylaminoethyl methacrylate (DMAEMA), 7.5g (75mmol) styrene (St), 7.38g (40mmol) isooctyl acrylate (EHA) , 5.8g (50mmol) of hydroxyethyl acrylate (HEA) was dissolved in 80mL of ethyl acetate, and then 0.886g of initiator azobisisobutyronitrile was added, nitrogen was passed through to remove oxygen for 30min, and the reaction was carried out at 80°C for 24h. After the reaction was completed, most of the solvent was removed by rotary evaporation, diluted with tetrahydrofuran (THF), and repeatedly precipitated with petroleum ether to obtain the copolymer PDHES;

[0041] (2) Dissolve 16g of the copolymer PDHES in 80mL of N,N-dimethylformamide (DMF), and then add 0.5g (2.6mmol) of 5-chloromethyl-8-hydroxyquinoline (CHQ) to the solution , 0.5g sodium iodide as a catalyst, 3g potassium carbonate as an acid-binding agent, reacted at 80°C for 24h, and repeatedly precipitated in ether to obtain a quaternized ammonium polymer. ...

Embodiment 3

[0045] (1) Synthesis of copolymer: Weigh 6.28g (40mmol) dimethylaminoethyl methacrylate (DMAEMA), 5.82g (58mmol) styrene (St), 11.80g (64mmol) isooctyl acrylate (EHA) , 4.64g (40mmol) of hydroxyethyl acrylate (HEA) was dissolved in 80mL of ethyl acetate, and then 0.886g of initiator azobisisobutyronitrile was added, deoxygenated by nitrogen gas for 30min, and reacted at 80°C for 24h. After the reaction was completed, most of the solvent was removed by rotary evaporation, diluted with tetrahydrofuran (THF), and repeatedly precipitated with petroleum ether to obtain the copolymer PDHES;

[0046] (2) Dissolve the copolymer PDHES16g in 80mL N,N-dimethylformamide (DMF), and then add 0.71g (3.5mmol) 5-bromomethyl-8-hydroxyquinoline (BHQ) to the solution, 3g of potassium carbonate was used as an acid-binding agent, reacted at 60°C for 24h, and repeatedly precipitated in ether to obtain a quaternized polymer. Dissolve 8g of quaternized polymer in 30mL of ethyl acetate, add 1.6g of is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com