3003 aluminum alloy plate and pretreatment process thereof

An aluminum alloy plate and process technology, applied in the field of 3003 aluminum alloy plate and its pretreatment process, can solve the problems of increasing the scrap rate, affecting the deep drawing process, and low strength, so as to reduce the product scrap rate, improve enterprise benefits, save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

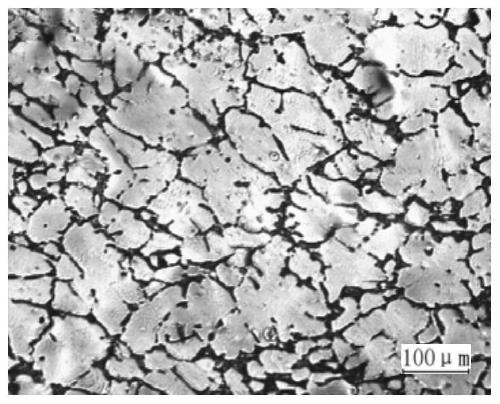

Embodiment 1

[0030] Embodiment 1 Preparation of a kind of 3003 aluminum alloy aluminum ingot

[0031] The first refining: Put the raw material 3003 aluminum ingot into the melting furnace, heat it to 680°C, then pour the refining agent into the molten aluminum while stirring, and then perform the first slag removal; the refining agent is based on the amount of 4% of the mass of the molten aluminum join in. Part of the refining agent is suspended on the surface of the molten aluminum to isolate the atmosphere, and the rest reacts with the aluminum slag to bring the aluminum slag out of the surface of the molten aluminum.

[0032] Secondary refining: After the first slag removal, the molten aluminum is stirred while being sprinkled with a refining agent, and then the second slag removal is performed; the refining agent is added in an amount of 2.5% based on the mass of the molten aluminum. Secondary slag removal can make the obtained molten aluminum cleaner.

[0033] First deterioration: a...

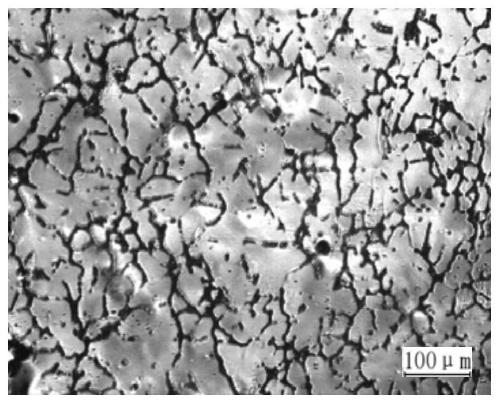

Embodiment 2

[0037] Embodiment 2 Preparation of a kind of 3003 aluminum alloy aluminum ingot

[0038] The first refining: Put the raw material 3003 aluminum ingot into the melting furnace, heat it to 700°C, then pour the refining agent into the molten aluminum while stirring, and then carry out the first slag removal; the amount of the refining agent is 3% based on the mass of the molten aluminum join in. Part of the refining agent is suspended on the surface of the molten aluminum to isolate the atmosphere, and the rest reacts with the aluminum slag to bring the aluminum slag out of the surface of the molten aluminum.

[0039] First deterioration: adding Al to molten aluminum after slag removal 5 TiB refiner and metal Ce, after stirring evenly, let it stand for 10-15min to obtain the first metamorphic aluminum liquid; in the first metamorphic step, the Al 5 The TiB refiner is added at 2% based on the mass of the first-modified molten aluminum; the metal Ce is added at 0.5% based on the ...

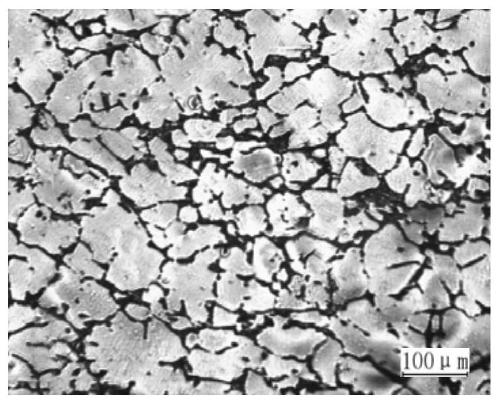

Embodiment 3

[0043] Embodiment 3 Preparation of a kind of 3003 aluminum alloy aluminum ingot

[0044]The first refining: put the raw material 3003 aluminum ingot into the melting furnace, heat it to 700°C, then pour the refining agent into the molten aluminum while stirring, and then carry out the first slag removal; the amount of the refining agent is 5% based on the mass of the molten aluminum join in. Part of the refining agent is suspended on the surface of the molten aluminum to isolate the atmosphere, and the rest reacts with the aluminum slag to bring the aluminum slag out of the surface of the molten aluminum.

[0045] Secondary refining: After the first slag removal, the molten aluminum is stirred while being sprinkled with a refining agent, and then the second slagging is performed; the refining agent is added in an amount of 3% based on the mass of the aluminum liquid. Secondary slag removal can make the obtained filtrate cleaner.

[0046] First deterioration: adding Al to mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com