Multilayer gradient biofilm and preparation method thereof

A biofilm and gradient technology, applied in drug delivery, pharmaceutical formulation, medical science, etc., can solve the problems of insufficient mechanical properties of natural polymers and excessive degradation speed, and achieve good cell and tissue compatibility and good biophase Capacitance, the effect of promoting bone tissue regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A kind of multilayer gradient biofilm that preferred embodiment of the present invention provides, its preparation method specific steps are as follows:

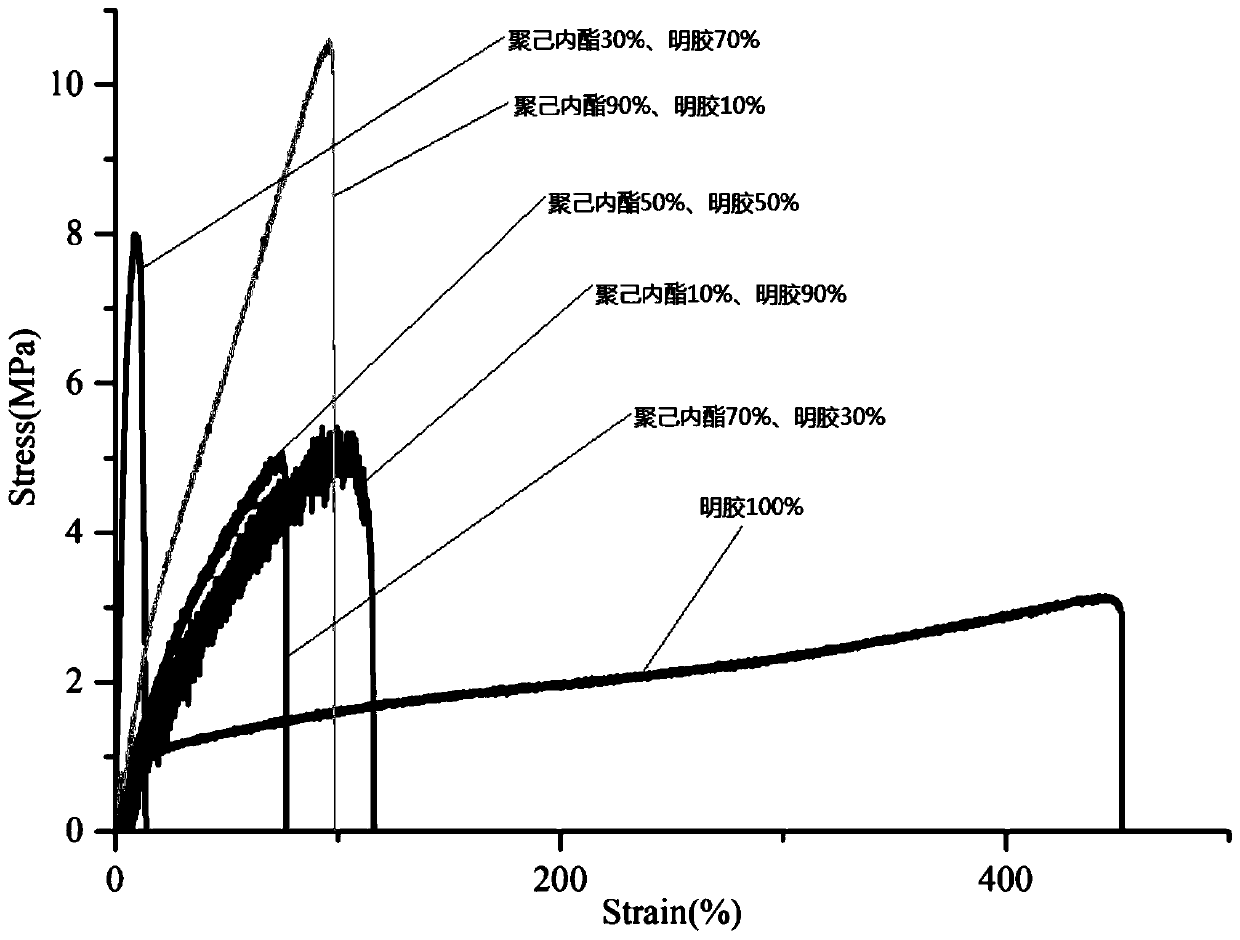

[0058] Dissolve 0.06g of polycaprolactone and 0.54g of gelatin in 5mL of trifluoroethanol under stirring at 25°C, add 0.015mL of acetic acid after they are completely dissolved and stir well to obtain a spinning polycaprolactone / gelatin Solution A: Dissolve 0.30g polycaprolactone and 0.30g gelatin in 5mL trifluoroethanol under stirring at 25°C, add 0.015mL acetic acid after they are completely dissolved and stir well to obtain polycaprolactone / gelatin spinning solution B; at 25°C, 0.0325g of nano-hydroxyapatite was added to 5mL of trifluoroethanol solution, ultrasonically oscillated at 350W for 60min, and then 0.455g of polycaprolactone and 0.195g of polycaprolactone were mixed under stirring Gelatin was dissolved in trifluoroethanol solution of hydroxyapatite to prepare spinning solution C of nano-hydroxyapatite / poly...

Embodiment 2

[0061] A kind of multilayer gradient biofilm that preferred embodiment of the present invention provides, its preparation method specific steps are as follows:

[0062] Dissolve 0.18g of polycaprolactone and 0.42g of gelatin in 5mL of trifluoroethanol under stirring at 25°C, add 0.015mL of acetic acid after they are completely dissolved and stir well to obtain a spinning polycaprolactone / gelatin Solution A: Dissolve 0.30g polycaprolactone and 0.30g gelatin in 5mL trifluoroethanol under stirring at 25°C, add 0.015mL acetic acid after they are completely dissolved and stir well to obtain polycaprolactone / gelatin Spinning solution B; at 25°C, add 0.065g nano-hydroxyapatite to 5mL trifluoroethanol solution, ultrasonically shake at 350W for 60min, then mix 0.455g polycaprolactone and 0.195g polycaprolactone under stirring Gelatin was dissolved in trifluoroethanol solution of hydroxyapatite to prepare spinning solution C of nano-hydroxyapatite / polycaprolactone / gelatin. Under the co...

Embodiment 3

[0065] A kind of multilayer gradient biofilm that preferred embodiment of the present invention provides, its preparation method specific steps are as follows:

[0066] Dissolve 0.30g of polycaprolactone and 0.30g of gelatin in 5mL of trifluoroethanol under stirring at 25°C, add 0.015mL of acetic acid after they are completely dissolved and stir well to obtain the spinning polycaprolactone / gelatin Solution A: Dissolve 0.30g polycaprolactone and 0.30g gelatin in 5mL trifluoroethanol under stirring at 25°C, add 0.015mL acetic acid after they are completely dissolved and stir well to obtain polycaprolactone / gelatin spinning solution B; at 25°C, add 0.0975g nano-hydroxyapatite to 5mL trifluoroethanol solution, ultrasonically shake at 350W for 60min, then mix 0.455g polycaprolactone and 0.195g polycaprolactone under stirring Gelatin was dissolved in trifluoroethanol solution of hydroxyapatite to prepare spinning solution C of nano-hydroxyapatite / polycaprolactone / gelatin. Under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com