A kind of liquid compound fertilizer and its preparation method and application

A compound fertilizer, liquid technology, applied in liquid fertilizer, application, phosphate fertilizer and other directions, can solve the problems of nitrogen and organic nutrient loss, and achieve the effect of reducing volatilization loss, cost, and volatilization loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

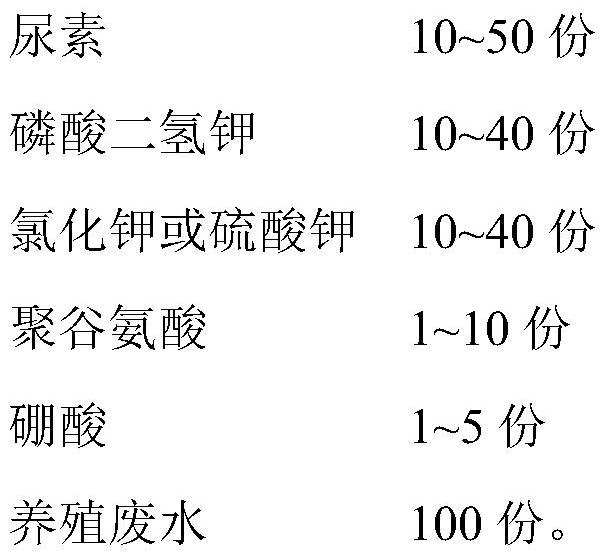

Image

Examples

Embodiment 1

[0024] The fresh biogas slurry is directly taken from the biogas slurry fermentation tank, and the biogas slurry is subjected to solid-liquid separation to remove solid impurity particles larger than 0.25mm in size. The nutrient content was measured, and the results were: pH 8.7, COD 19212g / kg, total nitrogen 1222mg / L, total phosphorus 96.2mg / L, and total potassium 1088mg / L.

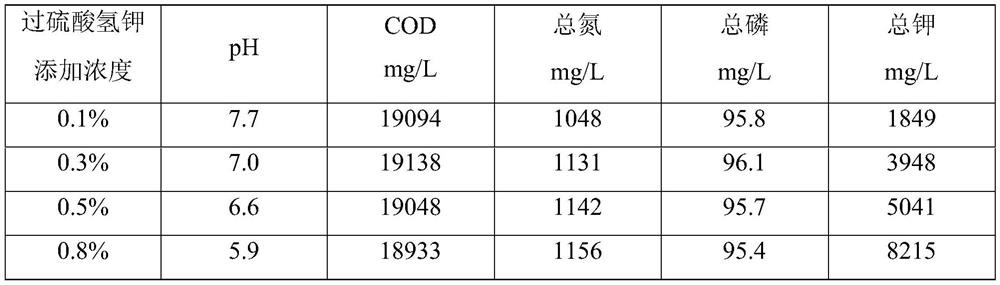

[0025] Table 1 Effect of pretreatment adding different concentrations of potassium persulfate on nutrient properties of biogas slurry

[0026]

[0027] Table 1 shows the changes in nutrient properties of biogas slurry after pretreatment with different concentrations of potassium persulfate. The 4 concentrations were aerated intermittently for 2 hours, then left for 2 hours, and then continued to aerate. After a total reaction time of 12 hours, the color of the solution became lighter and the odor disappeared. The results showed that the pH of the biogas slurry became neutral or acidic after adding fo...

Embodiment 2

[0031] The biogas slurry is obtained from the biogas slurry storage tank, and the biogas slurry is subjected to solid-liquid separation to remove solid impurity particles larger than 0.25mm in size. The nutrient content was measured, and the results were: pH8.8, COD8651g / kg, total nitrogen 287mg / L, total phosphorus 32.5mg / L, and total potassium 839mg / L.

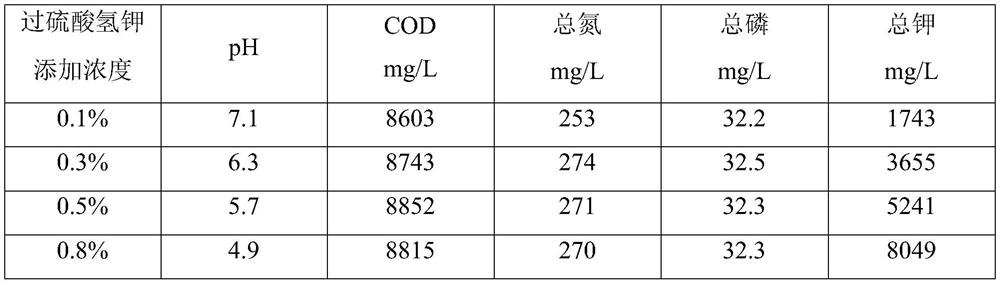

[0032] Table 2 Effect of adding different concentrations of potassium hydrogen persulfate in pretreatment on nutrient properties of biogas slurry

[0033]

[0034] Table 2 shows the changes in nutrient properties of biogas slurry after pretreatment with different concentrations of potassium persulfate. The 4 concentrations were intermittently aerated for 2 hours, then left for 2 hours, and then continued to aerate. After a total reaction time of 6 hours, the color of the solution became lighter and transparent, and the odor disappeared. The results showed that after 0.3wt%, 0.5wt%, and 0.8wt% potassium persulfate treatmen...

Embodiment 3

[0038] The vesicle manure solution is obtained from the vesicle manure storage tank, and it is subjected to solid-liquid separation to remove solid impurity particles larger than 0.25 mm in size. The nutrient content was measured, and the results were: pH 7.6, COD 2654g / kg, total nitrogen 194mg / L, total phosphorus 29.3mg / L, and total potassium 641mg / L.

[0039] Table 3 Effect of adding different concentrations of potassium hydrogen persulfate pretreatment on nutrient properties of blistered manure solution

[0040]

[0041]Table 3 shows the changes in the nutrient properties of the vesicular manure solution after pretreatment with different concentrations of potassium persulfate. The 4 concentrations were aerated for 2 hours and then placed for 2 hours. After a total reaction time of 4 hours, the color of the solutions became lighter and more transparent, and the odor disappeared. The results showed that after treatment with four concentrations of potassium hydrogen persul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com