Road guardrail plastic masterbatch for purifying automobile exhaust and preparation method thereof

A technology of automobile exhaust and plastic masterbatch, applied in the field of plastic masterbatch, can solve the problems of unsatisfactory efficiency, affecting purification efficiency, insufficient adsorption, etc., achieve good photocatalytic activity and visible light utilization rate, excellent purification effect, and significant purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

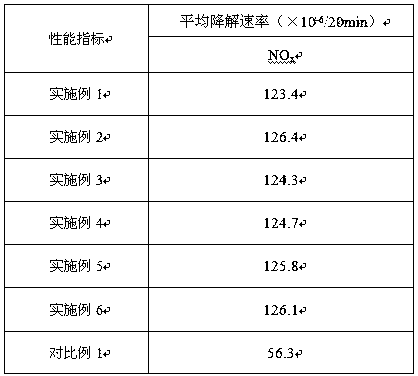

Examples

Embodiment 1

[0024] Mix 97kg of cyanoamine with 3kg of nano-calcium carbonate, grind at a speed of 260r / min for 34min, then move it into a tube furnace, heat it to 500°C for 2h under the atmosphere of argon, and then continue to grind the product 48min, after the end, it was washed 3 times with hydrochloric acid with a mass concentration of 13%, then washed 3 times with distilled water, and dried to obtain nanoscale porous graphite carbon nitride; then 17kg porous graphite carbon nitride, 8kg titanium Add tetrabutyl nitrate into 34g of absolute ethanol, stir vigorously at a speed of 500~600r / min for 30~40min to obtain solution A; then immerse 27kg of graphene airgel in solution A, and add 11kg of nitric acid / dehydrated ethanol Mixed solution, in the mixed solution of nitric acid / absolute ethanol, the volume ratio of nitric acid with a mass concentration of 15% and absolute ethanol is 7:93, and continue to stir at a speed of 360r / min until a sol is formed; then slowly add 3kg Sodium borohyd...

Embodiment 2

[0029] Mix 96kg of dicyanoamine with 4kg of nano-calcium carbonate, grind at a speed of 220r / min for 38min, then move it into a tube furnace, heat it to 400°C for 3h under the atmosphere of argon, and then continue to grind the product 45min, after the end, it was washed 4 times with hydrochloric acid with a mass concentration of 12%, then washed 2 times with distilled water, and dried to obtain nano-scale porous graphite carbon nitride; then 16kg porous graphite carbon nitride, 7kg titanium Tetrabutyl acid was added in 38kg of absolute ethanol, stirred vigorously at a speed of 520r / min for 38min to obtain solution A; then 27kg of graphene airgel was immersed in solution A, and 9kg of nitric acid / dehydrated ethanol mixed solution was added, nitric acid In / dehydrated ethanol mixed solution, mass concentration is 10% nitric acid, the volume ratio of absolute ethanol is 6:94, continues to stir until forming sol with the rotating speed of 320r / min; Slowly add 3kg sodium borohydride...

Embodiment 3

[0032] Mix 98kg melamine with 2kg nano-calcium carbonate, grind at a speed of 280r / min for 32min, then move it into a tube furnace, heat it to 500°C for 2h under the atmosphere of argon, then continue grinding the product for 55min, and end After that, it was washed 4 times with hydrochloric acid with a mass concentration of 14%, then washed 3 times with distilled water, and dried to obtain nano-scale porous graphite carbon nitride; then 17kg porous graphite carbon nitride, 9kg tetrabutyl titanate Add the ester to 31kg of absolute ethanol, stir vigorously at a speed of 580r / min for 32min to obtain solution A; then immerse 28kg of graphene airgel in solution A, and add 11kg of nitric acid / dehydrated ethanol mixed solution, nitric acid / dehydrated In the ethanol mixed solution, the volume ratio of nitric acid with a mass concentration of 20% and absolute ethanol is 9:91, and continue to stir at a speed of 380r / min until a sol is formed; then slowly add 4kg of sodium borohydride to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com