Anodic oxidation preparation method for antibacterial colorful aluminum or aluminum alloys

An anodic oxidation and aluminum alloy technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of increasing production cost, reducing production efficiency, increasing process steps, etc., to achieve high workpiece output efficiency, reduce Valueless consumption, the effect of simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

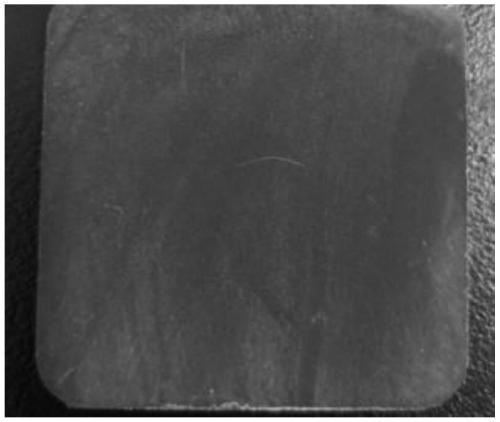

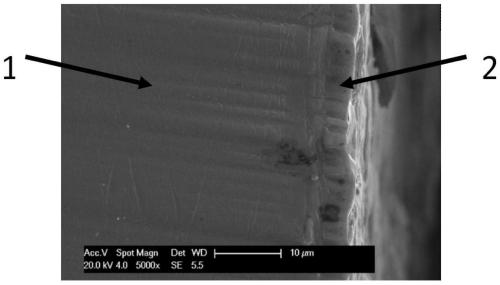

Image

Examples

Embodiment 1

[0029] Two pieces of 6063 aluminum alloy materials are selected as workpieces to be processed, and the specific steps of the preparation method are as follows:

[0030] S1. Put two pieces of 6063 aluminum alloy into a solution containing 40g / L sodium hydroxide and 20g / L sodium carbonate for alkaline washing to remove oil, at a temperature of 40°C, take out and wash with water after 2 minutes;

[0031] S2. Put the aluminum alloy into a solution containing 60g / L sulfuric acid and 10g / L sodium nitrate to neutralize the lye and emit light, take it out and wash it with water after 1 minute at room temperature;

[0032] S3, prepare electrolytic solution, electrolytic solution is 150g / L sulfuric acid, 5g / L silver nitrate, 10g / L cerium nitrate, 1g / L copper sulfate, 1g / L stannous sulfate, 15g / L magnesium sulfate, 10g / L boric acid, 1g / L ammonium sulfate solution;

[0033] S4. Immerse the two 6063 aluminum alloys with clean surfaces obtained in step 2 into the electrolyte obtained in st...

Embodiment 2

[0040] Two pieces of 5052 aluminum alloy materials are selected as workpieces to be processed, and the specific steps of the preparation method are as follows:

[0041] S1. Put two pieces of 5052 aluminum alloy into a solution containing 40g / L sodium hydroxide and 20g / L sodium carbonate for alkali washing to remove oil, at a temperature of 40°C, take out and wash with water after 2 minutes;

[0042] S2. Put the aluminum alloy into a solution containing 60g / L sulfuric acid and 10g / L sodium nitrate to neutralize the lye and emit light, take it out and wash it with water after 1 minute at room temperature;

[0043] S3, prepare electrolytic solution, electrolytic solution is 180g / L sulfuric acid, 1g / L silver nitrate, 1g / L cerium nitrate, 10g / L copper sulfate, 5g / L stannous sulfate, 3g / L magnesium sulfate, 22g / L boric acid, 6g / L ammonium sulfate solution;

[0044] S4. Immerse the two 6063 aluminum alloys with clean surfaces obtained in step 2 into the electrolyte obtained in step ...

Embodiment 3

[0051] Two pieces of pure aluminum materials are selected as workpieces to be processed, and the specific steps of the preparation method are as follows:

[0052] S1. Put two pieces of pure aluminum materials into a solution containing 40g / L sodium hydroxide and 20g / L sodium carbonate for alkaline washing to remove oil at a temperature of 40°C. After 2 minutes, take them out and wash them with water;

[0053] S2. Put two pieces of pure aluminum into a solution containing 60g / L sulfuric acid and 10g / L sodium nitrate to neutralize the lye and emit light, take it out and wash it with water after 1 minute at room temperature;

[0054] S3, preparation electrolyte, electrolyte is 200g / L sulfuric acid, 1.5g / L silver nitrate, 3g / L cerium nitrate, 6g / L copper sulfate, 8g / L stannous sulfate, 6g / L magnesium sulfate, 30g / L boric acid , 10g / L solution of ammonium sulfate;

[0055] S4. Immerse the two pieces of pure aluminum with clean surfaces obtained in step 2 into the electrolyte obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com