GABA-rich yogurt and preparation method thereof

A technology for yogurt and milk, which is applied in the field of GABA-rich yogurt and its preparation, which can solve the problems of poor functionality and low GABA content, and achieve the effects of simplifying production operation steps, high GABA content, and improving the overall sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

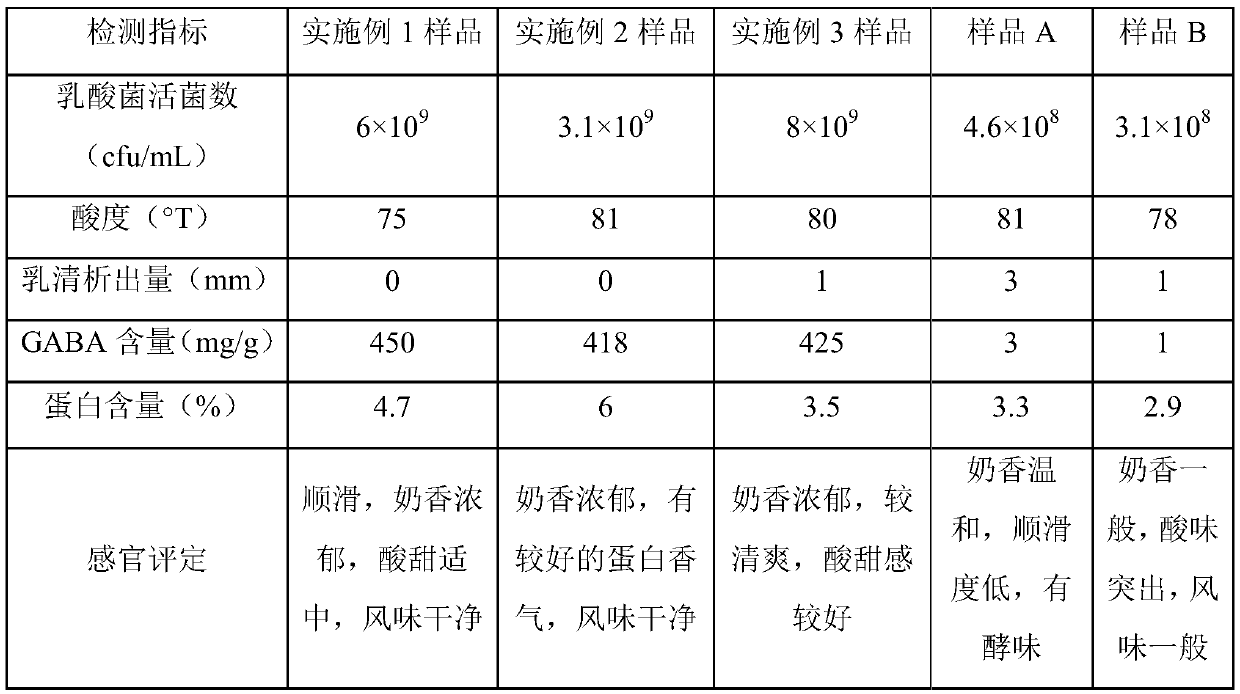

Examples

Embodiment 1

[0032]A yogurt rich in GABA, comprising the following components in mass percentage: 84.5% of milk or reconstituted milk, 8% of sweetener, 0.1% of sodium glutamate, 5% of compound bacterial agent, and 2.4% of concentrated protein powder; The mass ratio of Lactococcus lactis subsp. lactis and Streptococcus thermophilus in the compound microbial agent is 5:95.

[0033] Among them, the Lactococcus lactis subsp. lactis is Lactococcus lactis subsp.lactis 220223, and the preservation number is CGMCC No.16584; No. 16585.

[0034] The mass ratio of concentrated whey protein powder A, concentrated whey protein powder B and concentrated milk protein powder in the concentrated protein powder is 1.8:0.7:1.2.

[0035] The preparation method of the above-mentioned yoghurt rich in GABA comprises the steps:

[0036] S1. Mixing: Put the reconstituted milk into the mixing tank, raise the temperature to 60°C, slowly add the concentrated protein powder in proportion while stirring at 700r / min, ...

Embodiment 2

[0041] A yogurt rich in GABA, comprising the following components in mass percentage: 80% of milk or reconstituted milk, 10% of white sugar, 1% of sodium glutamate, 4% of compound bacterial agent, and 5% of concentrated protein powder; The mass ratio of Lactococcus lactis subsp. lactis and Streptococcus thermophilus in the compound bacterial agent is 1:99.

[0042] Among them, the Lactococcus lactis subsp. lactis is Lactococcus lactis subsp.lactis 220223, and the preservation number is CGMCC No.16584; No. 16585.

[0043] The mass ratio of concentrated whey protein powder A, concentrated whey protein powder B and concentrated milk protein powder in the concentrated protein powder is 1:1:1.

[0044] The preparation method of the above-mentioned yoghurt rich in GABA comprises the steps:

[0045] S1. Mixing: Put the raw milk into the mixing tank, raise the temperature to 55°C, slowly add the concentrated protein powder in proportion while stirring at 800r / min, stir at 50°C for 2...

Embodiment 3

[0050] A yogurt rich in GABA, comprising the following components in mass percentage: 95% of milk or reconstituted milk, 4% of white sugar, 0.4% of sodium glutamate, 0.1% of compound bacterial agent, and 0.5% of concentrated protein powder; The mass ratio of Lactococcus lactis subsp. lactis and Streptococcus thermophilus in the compound bacterial agent is 10:90.

[0051] Among them, the Lactococcus lactis subsp. lactis is Lactococcus lactis subsp.lactis 220223, and the preservation number is CGMCC No.16584; No. 16585.

[0052] The mass ratio of concentrated whey protein powder A, concentrated whey protein powder B and concentrated milk protein powder in the concentrated protein powder is 3:0.5:2.

[0053] The preparation method of the above-mentioned yoghurt rich in GABA comprises the steps:

[0054] S1. Mixing: Put the reconstituted milk into the mixing tank, raise the temperature to 70°C, slowly add the concentrated protein powder in proportion while stirring at 500r / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com