Handmade yogurt sugar and making method thereof

A yogurt candy and manual technology, applied to bacteria used in food preparation, confectionery, confectionery industry, etc., can solve the problems of complex production process, high cost, and complicated raw materials, and achieve high nutritional content, low water content, Simple Effects of Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

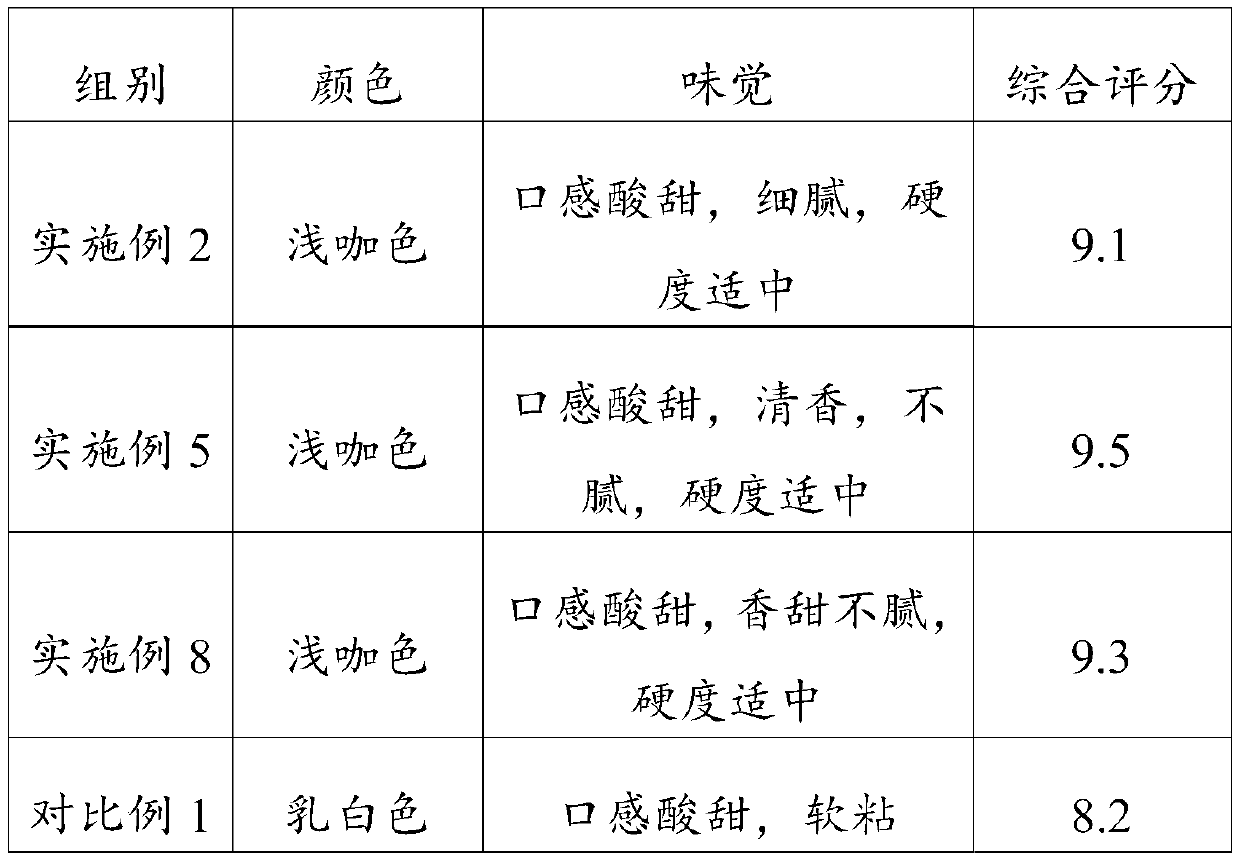

Examples

Embodiment 1

[0031] Artisan Yogurt Candies, including ingredients by weight:

[0032] 700 g of cream, 1000 g of white sugar, and 100 g of whey fermentation concentrate; the milk fat content of the cream is 43%, and the pH of the whey fermentation concentrate is 4.

[0033] The preparation method of above-mentioned handmade yogurt candy, comprises the following steps:

[0034] (1) Preparation of whey fermentation concentrate: take sterilized milk, insert into lactic acid bacteria for fermentation, separate upper layer solids to obtain lower layer fermented skim milk, heat fermented skim milk to 50°C for 15 minutes, then carry out solid-liquid separation, discard Solid, to obtain whey; sterilize the whey, adjust the temperature to 40 ° C, add acid protease, enzymatically hydrolyze for 3 hours to obtain a whey enzymatic hydrolysate; sterilize the whey enzymatic hydrolysate, and then adjust the temperature to 18 ℃, inoculate 0.05% mixed bacteria, the mixed bacteria includes Lactobacillus case...

Embodiment 2

[0037] Artisan Yogurt Candies, including ingredients by weight:

[0038] Cream 1000g, white sugar 1000g, whey fermentation concentrate 80g, the milk fat content of the cream is 50%, the pH of the whey fermentation concentrate is 3,

[0039] The preparation method of above-mentioned handmade yogurt candy, comprises the following steps:

[0040] (1) Preparation of whey fermentation concentrate: take sterilized milk, insert into lactic acid bacteria for fermentation to obtain yogurt, heat the yogurt to 60°C for 10 minutes, then carry out solid-liquid separation, discard the solid to obtain whey; Sterilize, adjust the temperature to 50°C, add acid protease, and enzymolyze for 2 hours to obtain a whey enzymolysate; sterilize the whey enzymolysate, then adjust the temperature to 20°C, and inoculate 5% mixed bacteria. The mixed bacteria include Lactobacillus casei and Lactococcus lactis, and the weight ratio of the Lactobacillus casei and Lactococcus lactis is 1:1, fermented at 20° ...

Embodiment 3

[0043] Artisan Yogurt Candies, including ingredients by weight:

[0044] Cream 1000g, white sugar 1000g, whey fermentation concentrate 100g, fried rice 500g, the milk fat content of the cream is 45%, and the pH of the whey fermentation concentrate is 3.7.

[0045] The preparation method of above-mentioned handmade yogurt candy, comprises the following steps:

[0046] (1) Preparation of whey fermentation concentrate: take sterilized milk, insert into lactic acid bacteria for fermentation, separate upper layer solids to obtain lower layer fermented skim milk, heat the fermented skim milk to 55°C for 12 min, then carry out solid-liquid separation, discard solid to obtain whey liquid; sterilize the whey liquid, adjust the temperature to 45°C, add acid protease, and enzymolyze for 2.5 hours to obtain a whey enzymatic hydrolysate; sterilize the whey enzymatic hydrolyzate, and then adjust the temperature to 20° C., inoculate 0.5% mixed bacteria, the mixed bacteria include Lactobacil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com