Preparation method of interaction network compound Bletilla striata dressing

A technology of network compounding and bletilla striata, applied in the field of biomedicine, can solve the problems of poor mechanical properties, different structures, and different components of gauze, and achieve the effects of ensuring mechanical strength, good adhesion to wounds, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

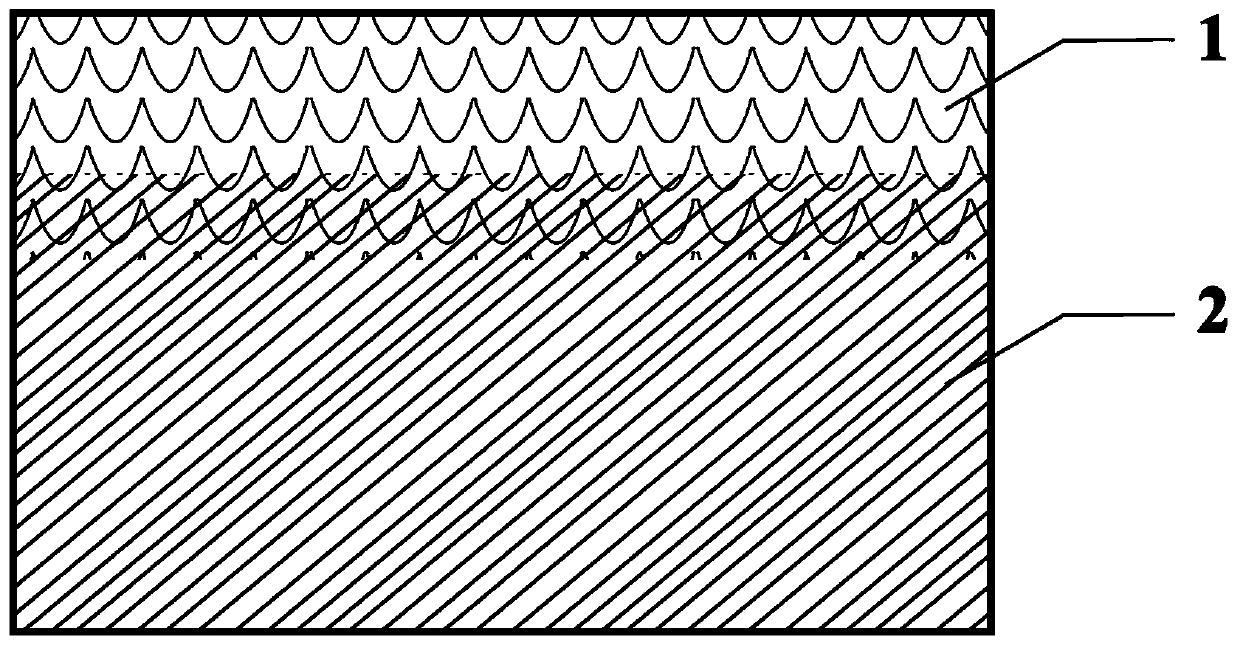

Image

Examples

preparation example Construction

[0031] A preparation method of interactive network composite bletilla striata dressing, the preparation method is carried out according to the following steps:

[0032] a Preparation of Bletilla striata polysaccharide casting solution

[0033] The bletilla striata polysaccharide solution is prepared by dissolving the bletilla striata polysaccharide in water to prepare a bletilla striata polysaccharide solution with a mass fraction of 3-10%, and placed in a vacuum state with a vacuum degree of 0.1-0.5 MPa to remove air bubbles to obtain a bletilla striata polysaccharide casting solution for future use.

[0034] b Preparation of dressing layer

[0035] Take part of the Bletilla striata polysaccharide casting solution prepared in step a and pour it into the groove of the flat mold, and use the freezing method to completely freeze the Bletilla striata polysaccharide casting solution in the flat mold to form a 3-8mm thick Bletilla striata polysaccharide film. The molded film is fr...

Embodiment 1

[0050] a Preparation of Bletilla striata polysaccharide casting solution

[0051] Dissolving Bletilla striata polysaccharide in water to prepare a Bletilla striata polysaccharide solution with a mass fraction of 3%, and placing it in a vacuum with a degree of vacuum of 0.1 MPa to remove air bubbles to obtain a Bletilla striata polysaccharide casting solution for future use.

[0052] b Preparation of dressing layer

[0053] Take part of the bletilla striata polysaccharide casting solution prepared in step a and pour it into the groove of the flat mold, and freeze the bletilla striata polysaccharide casting solution in the flat mold completely by freezing to form a 3 mm thick bletilla striata polysaccharide film. Freeze-dry in an environment with a temperature of -10°C and a vacuum of 1 Pa, and take it out after 24 hours to obtain the adhesive layer dressing 2.

[0054] Wherein, the length of the above-mentioned flat mold groove is 10mm, the width is 10mm, and the height is 5mm...

Embodiment 2

[0065] a Preparation of Bletilla striata polysaccharide casting solution

[0066] Dissolving the Bletilla striata polysaccharide in water to prepare a Bletilla striata polysaccharide solution with a mass fraction of 10%, and placing it in a vacuum state with a vacuum degree of 0.5 MPa to remove air bubbles to obtain a Bletilla striata polysaccharide casting solution for future use.

[0067] b Preparation of dressing layer

[0068] Take part of the bletilla striata polysaccharide casting solution prepared in step a and pour it into the groove of the flat mold, and freeze the bletilla striata polysaccharide casting solution in the flat mold completely by freezing to form a bletilla striata polysaccharide film with a thickness of 8mm. Freeze-dry in an environment with a temperature of -60°C and a vacuum of 20 Pa, and take it out after 48 hours to obtain the adhesive layer dressing 2.

[0069] Wherein, the length of the above-mentioned flat mold groove is 200mm, the width is 100m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com