Method for solidifying tailing sands by active magnesium oxide-based microorganisms, and product thereof

A technology of activated magnesia and tailings sand, which is applied in the field of tailings sand solidification, can solve problems such as difficulty in ensuring the uniformity of solidified samples, easy cracks on the surface of samples, and high heavy metal content in tailings sand, achieving good application prospects and environmental benefits The effect of economic benefits and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the cultivation of bacteria

[0030] The method of bacterial culture is as follows: take Bacillus strains, after being activated by streaked plate culture, pick a single colony for preliminary expansion culture, and then inoculate it into a Erlenmeyer flask for amplified culture, and cultivate it to the logarithmic growth phase. The urease activity is 2.4mmol urea / (L·min), spare. The main components of the culture medium used by bacteria are as follows: 20g / L peptone, 10g / L urea, 5g / L sodium chloride.

Embodiment 2

[0031] Embodiment 2, the preparation of brick mold

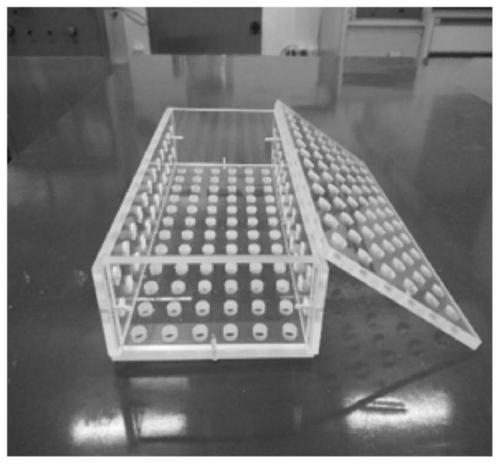

[0032] In order to carry out the curing experiment better, a mold for making bricks from magnesia microbially solidified tailings sand was designed and processed. The box (240×115mm) and the left and right side panels (240×53mm) are evenly arranged with circular holes with a diameter of about 1.0cm, which can adjust the micro-expansion of the solidified tailings sand, and is conducive to the discharge of water and CO in the air. 2 The absorption; the internal size is 240×115×53mm (standard brick size), the assembled mold is as follows figure 1 shown. The brick-making mold adopts a combined structure, is easy to disassemble and can be used repeatedly.

Embodiment 3

[0033] Embodiment 3, the solidification of tailings sand adds

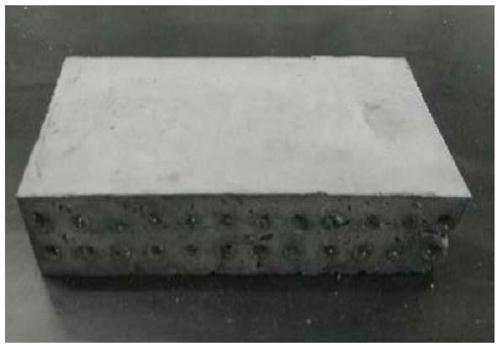

[0034] Get the bacillus 200ml that embodiment 1 cultivates, adopt activity (iodine absorption value) to be 120 active magnesium oxide 250g, add the urea solution 400ml that concentration is 3mol / L, get the tailing sand 2250g of certain manganese slag tailings pond, dry Finally, remove particles and debris with a particle size greater than 1cm; firstly mix 250g of active magnesium oxide and 2250g of tailings sand evenly, then mix and stir with urea solution, then add bacterial solution and mix evenly, then pour into the mold, and layer and compact to Design dry density 1.7g / L, let stand for 6 hours, the result is as follows figure 2 shown. After curing, the mold is removed, and the surface is polished to obtain cured tailings sand bricks, such as image 3 shown. It can be seen from the figure that the bricks after demoulding are complete and the surface is relatively smooth, and the curing condition is good, ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com