Method for recycling methyl chloride tail gas in chemical production process

A recovery method and production process technology, which is applied in the field of recovery of methyl chloride tail gas, can solve the problems of low operating temperature, energy consumption and large equipment investment, and achieve the effects of improving recovery rate, reducing construction and operating costs, and easily obtaining losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

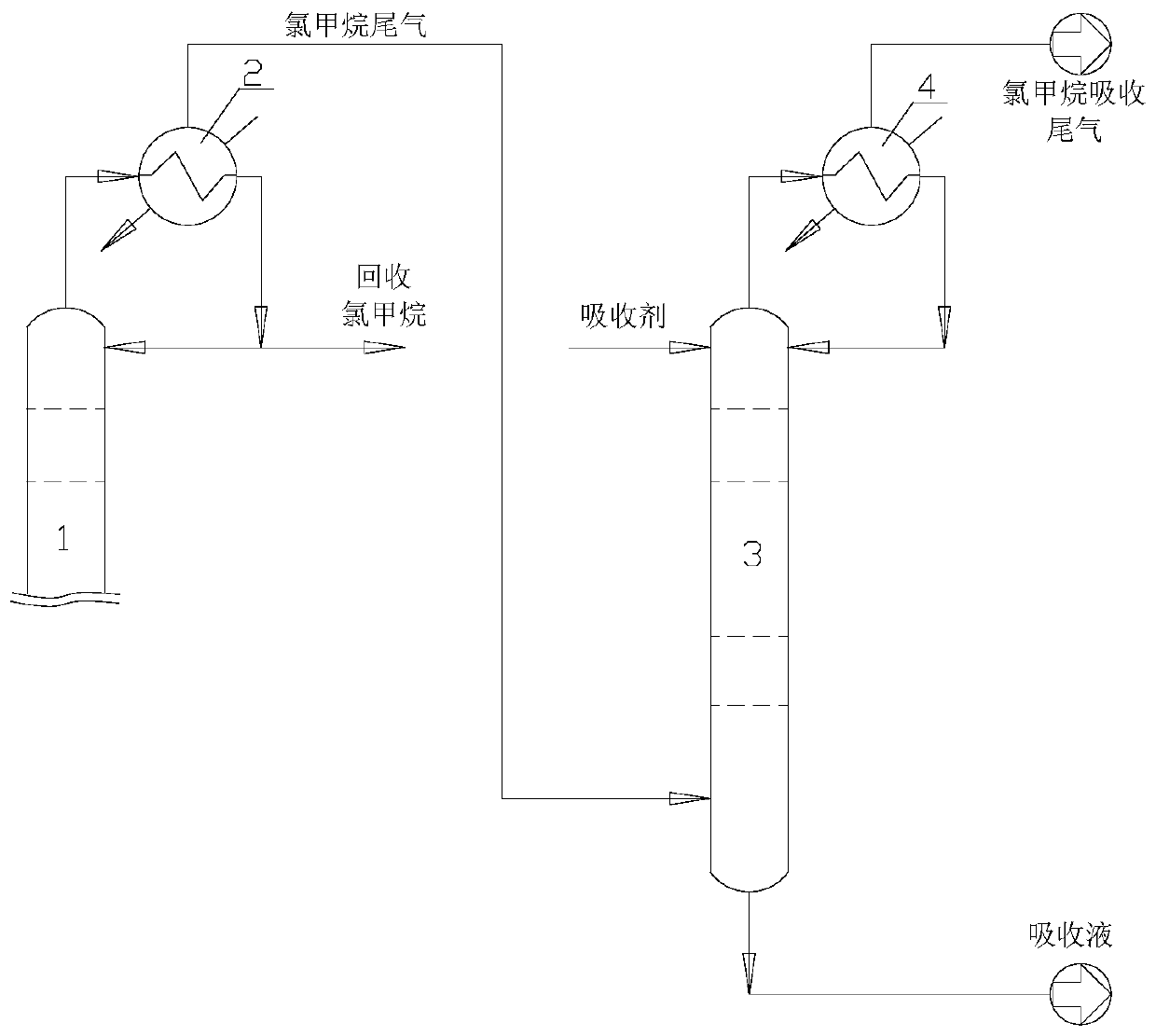

Image

Examples

Embodiment 1

[0045]Example 1: In a certain set of 60,000 tons / year methyl chlorosilane crude monomer synthesis device, the normal flow rate of non-condensable gas exiting the separation tower condenser 2 is 725 kg / h, wherein the flow rate of methyl chloride is 290 kg / h.

[0046] Using the method and equipment of the present invention, when the absorbent is methanol, under the mass flow rate of the preferred absorbent and non-condensable gas containing chloromethane, methanol is added from the top of the absorption tower 3, and the absorption tower condenser 4 is set to recover the methanol and return to the absorption tower. Out of the tail gas of the absorption tower condenser 4, methyl chloride is ≤0.001kg / h, which is almost completely absorbed, and the recovery rate of methyl chloride is ≥99.99%.

[0047] After absorption, a small amount of methanol is taken away in the tail gas, and the loss rate of methanol is ≤0.2%. The cooling capacity consumed by the absorption tower condenser 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com