Preparation method of phosphonitrile polymeric flame retardant

A technology of polymer flame retardant and phosphazene, which is applied in the field of preparation of polymer flame retardant, can solve the problems of the influence of mechanical properties of flame retardant materials, different flame retardants, etc., and achieves extensive research and application prospects, good thermal performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

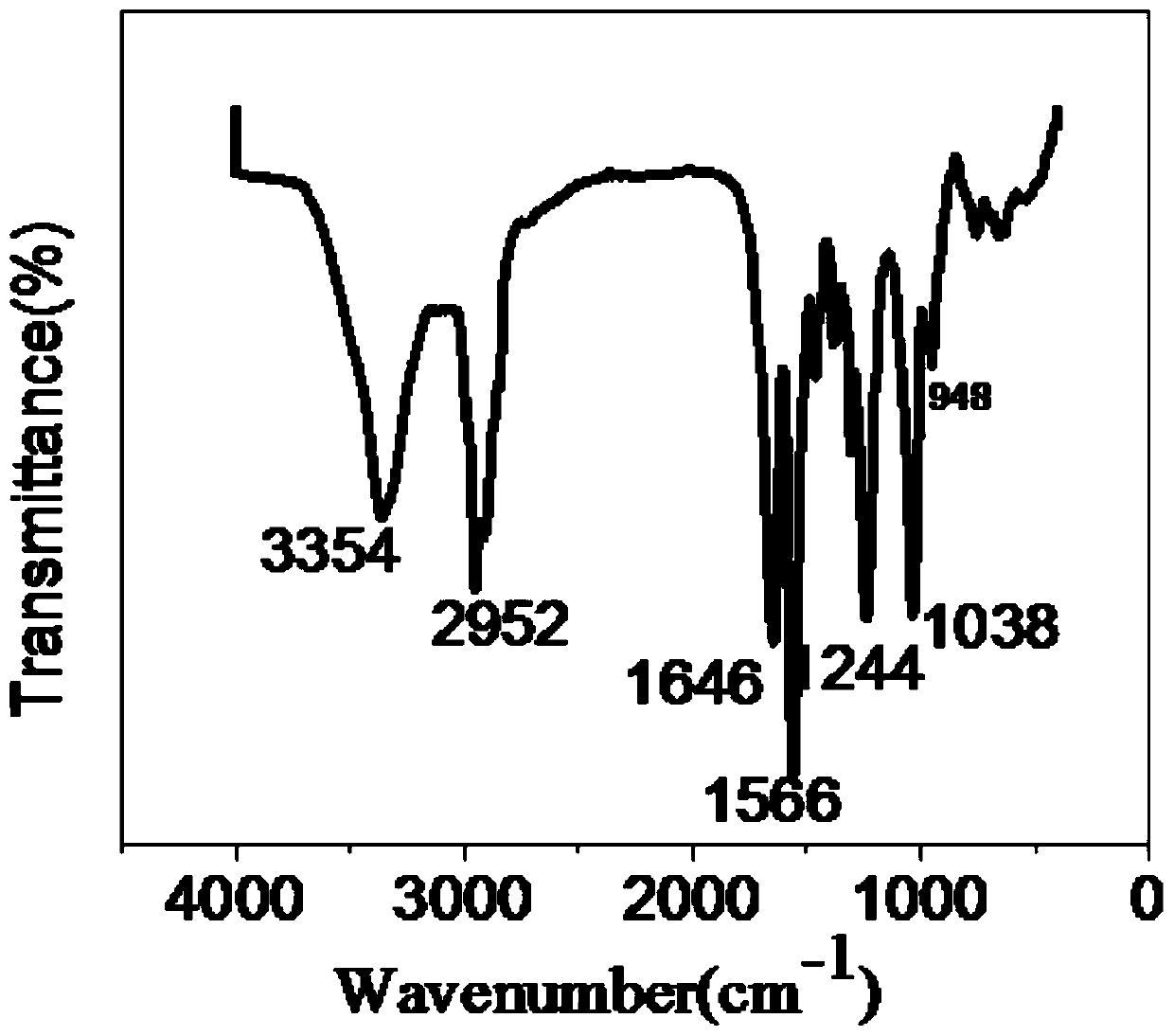

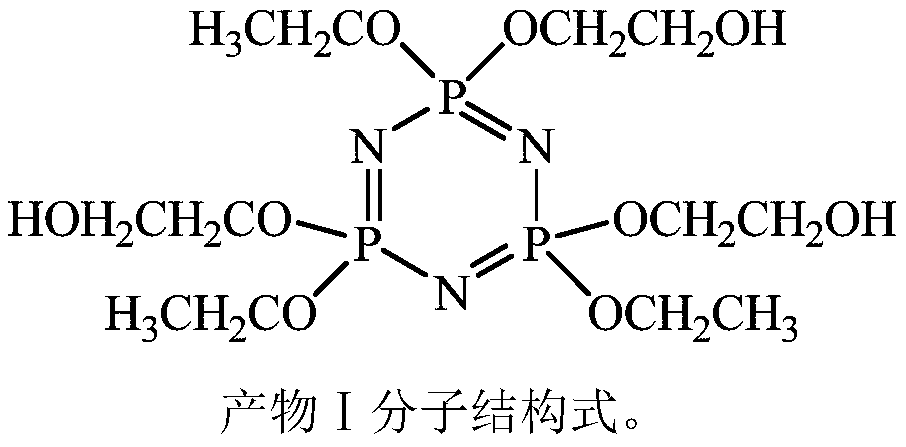

[0029] Into a 250ml three-necked flask, add 40ml of THF after dehydration and 4.32g of NaH in sequence, pass nitrogen protection, and stir magnetically throughout. Add 11.16g of ethylene glycol dropwise into the three-necked flask with a dropping funnel, and the dropping rate can be controlled at every two seconds. After the dropwise addition, the temperature was raised to 60°C, and the reaction was continued for 2 hours to obtain monosodium ethylene glycol.

[0030] Another 250ml three-neck flask was taken, and 40ml of THF after dehydration and 4.32gNaH were successively added into the three-necked flask, protected by nitrogen gas, and magnetically stirred throughout. 8.28g of ethanol was added dropwise into the three-necked flask with a dropping funnel, and the rate of addition was controlled at one drop every two seconds. After the dropwise addition, the temperature was raised to 60°C, and the reaction was continued for 2 hours to obtain sodium ethoxide.

[0031] The prep...

Embodiment 2

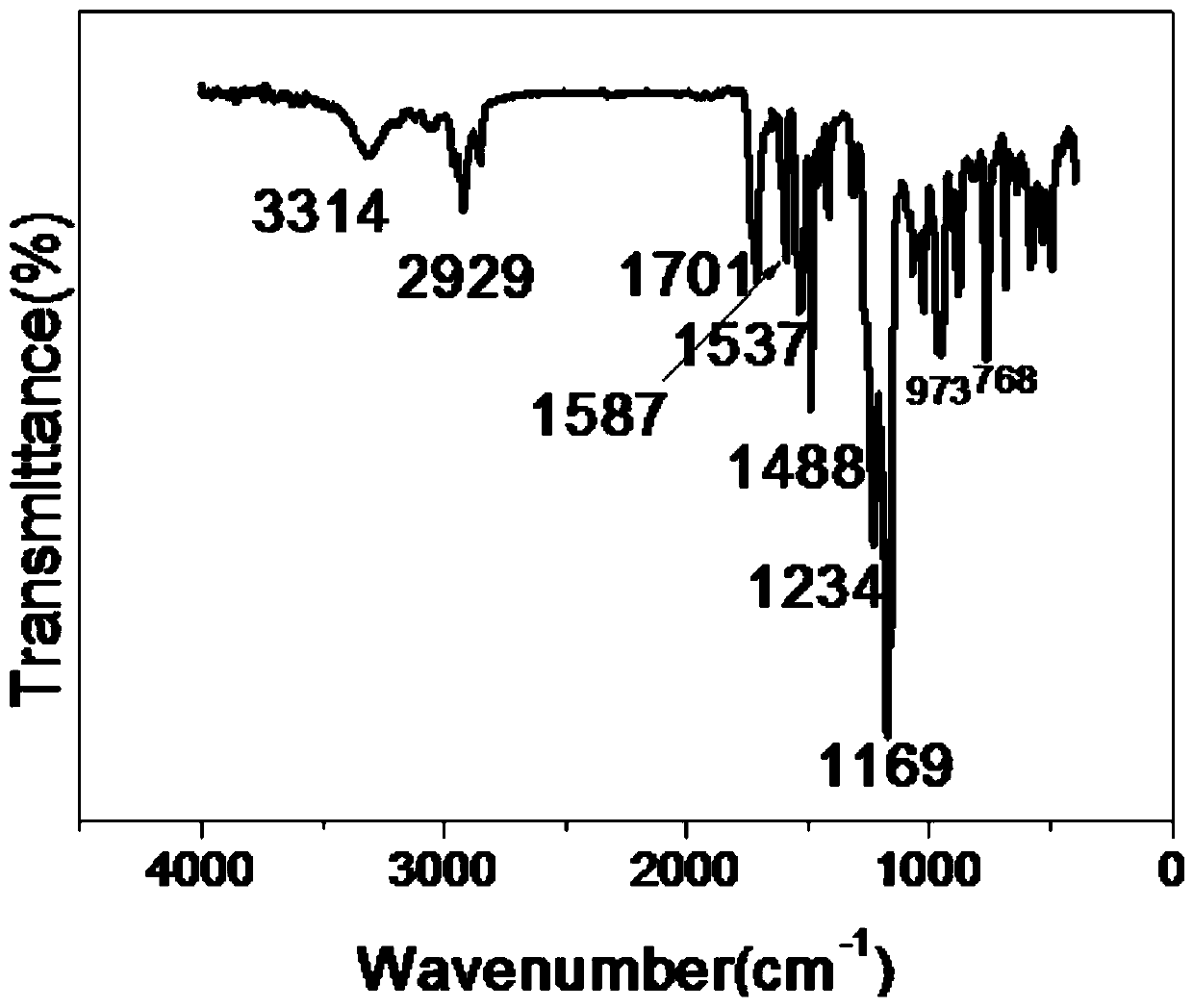

[0033] Add 40ml of THF and 4.32g of NaH after dehydration to a 250ml three-necked flask in sequence, and pass nitrogen gas for five minutes to remove the air in the flask, and stir magnetically throughout. Add the phenol tetrahydrofuran solution dropwise into the three-necked flask with a dropping funnel. Note that the melting point of phenol is 43°C, and it is solid at room temperature. Therefore, it is heated and dissolved in tetrahydrofuran before weighing and added dropwise. After the dropwise addition was completed, the temperature was raised to 60° C., and the reaction was continued for 2 h to obtain sodium phenoxide. Dissolve HCCP in tetrahydrofuran and add dropwise into the mixed solution of sodium phenate and monosodium ethylene glycol. The molar ratio of the reaction feed is HCCP: sodium phenate: monosodium ethylene glycol = 1:3:3. After the dropwise addition, the temperature was raised to 60° C., stirred by magnetic force, and the reaction was continued for 12 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com