A preparation method of a novel copper alloy for medical devices with bactericidal and antibacterial functions

A technology for medical devices and copper alloys, which is applied in the field of preparation of copper alloys for new medical devices, can solve the problems of easy discoloration and low strength of copper alloys, and achieve the effects of increasing corrosion resistance, improving mechanical strength, and uniform composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

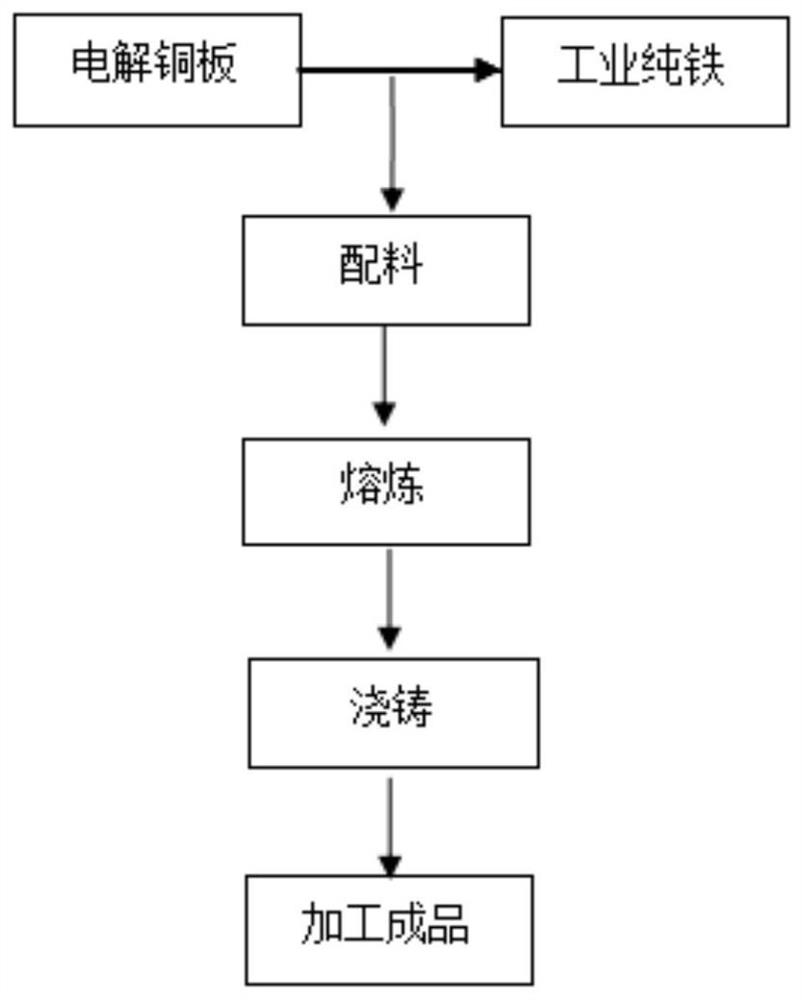

[0029] A method for preparing a novel copper alloy for medical devices with bactericidal and antibacterial functions, mainly comprising the following steps:

[0030] (1) Ingredients

[0031]Taking by weight percentage is 6% industrial pure iron, 94% electrolytic copper plate, stand-by;

[0032] (2) Melting

[0033] First, add the industrial pure iron in the above weight ratio to the non-vacuum intermediate frequency induction furnace. After the industrial pure iron is melted, then add the electrolytic copper plate in the above weight ratio and keep it at 1300°C for 30 minutes. Use a quartz glass tube to stir evenly and degas , refining, and finally use charcoal to cover and keep warm for 30 minutes to prepare for casting;

[0034] (3) casting

[0035] When the above-mentioned alloy liquid holding time is over, quickly remove the charcoal covered on the surface, and use an infrared thermometer to measure the casting temperature, and then carry out casting, which uses a water...

Embodiment 2

[0039] A method for preparing a novel copper alloy for medical devices with bactericidal and antibacterial functions, mainly comprising the following steps:

[0040] (1) Ingredients

[0041] Weigh industrial pure iron with a percentage by weight of 3-10%, and the balance is an electrolytic copper plate for use;

[0042] (2) Melting

[0043] First, carry out surface pretreatment on the industrial pure iron and electrolytic copper plates. The specific treatment process is as follows: put the industrial pure iron and electrolytic copper plates into acetone solution with a purity of 99.7%, clean the surface for 15 minutes with ultrasonic waves, and then wash the Put the industrial pure iron and electrolytic copper plate into the drying box respectively, and dry them for 1.3h under the condition of hot air circulation at 55°C. The ultrasonic power is 3.5KW and the frequency is 60kHz. , can remove impurities on its surface, and avoid impurities affecting the purity and performance...

Embodiment 3

[0049] A method for preparing a novel copper alloy for medical devices with bactericidal and antibacterial functions, mainly comprising the following steps:

[0050] (1) Ingredients

[0051] Weigh industrial pure iron with a percentage by weight of 3-10%, and the balance is an electrolytic copper plate for use;

[0052] (2) Melting

[0053] First, carry out surface pretreatment on the industrial pure iron and electrolytic copper plates. The specific treatment process is as follows: put the industrial pure iron and electrolytic copper plates into acetone solution with a purity of 99.7%, clean the surface for 15 minutes with ultrasonic waves, and then wash the Put the industrial pure iron and electrolytic copper plate into the drying box respectively, and dry them for 1.3h under the condition of hot air circulation at 55°C. The ultrasonic power is 3.5KW and the frequency is 60kHz. , can remove impurities on its surface, and avoid impurities affecting the purity and performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com