Antibacterial formaldehyde-free UV blockboard and preparation technology thereof

A woodworking board and functional technology, applied in the direction of wood layered products, manufacturing tools, wood treatment, etc., can solve the problems of poor antibacterial performance and achieve the effect of prolonging the effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

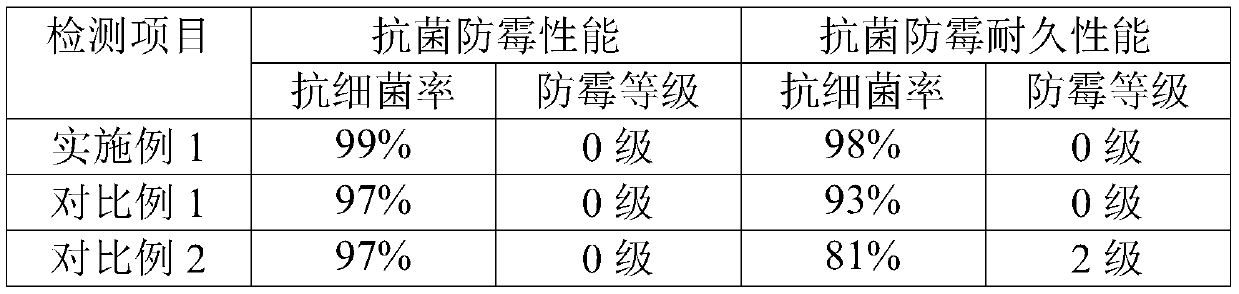

Embodiment 1

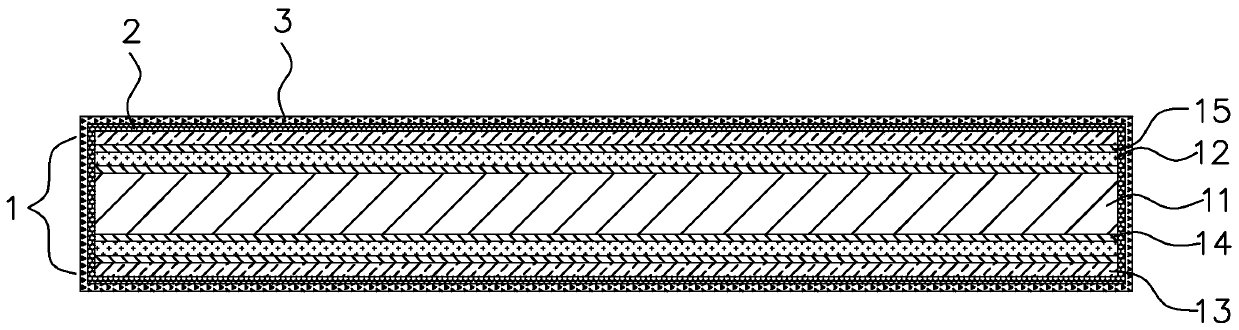

[0037] Such as figure 1 As shown, in this embodiment, a formaldehyde-free UV woodworking board with antibacterial function comprises a base material 1, an antibacterial layer 2 and a UV curable layer 3 in sequence.

[0038] Wherein, the substrate 1 sequentially includes a blockboard layer 11, a first adhesive layer 14, a poplar veneer layer 12, a second adhesive layer 15 and an Okoume board layer 13, in order to fundamentally reduce woodworking The amount of formaldehyde released from the board, in this embodiment, both the first adhesive layer 14 and the second adhesive layer 15 use soybean gum.

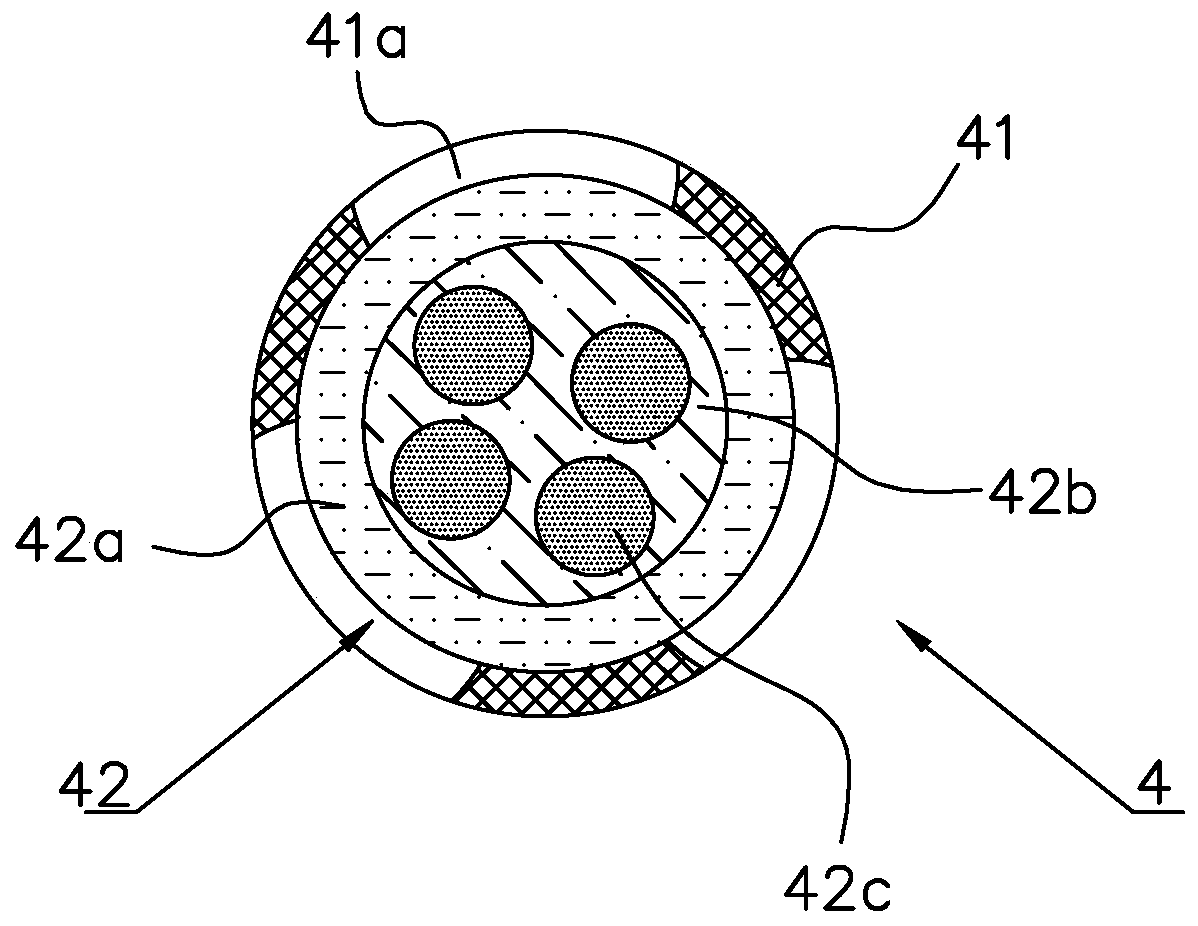

[0039] Such as figure 2 As shown, the antibacterial layer 2 contains aldehyde-removing antibacterial microspheres 4, and the aldehyde-removing antibacterial microspheres 4 include nanopolymer hollow microspheres 41, and the water-in-oil liquid permeates from the pores of the nanopolymer hollow microspheres 41 to the center. droplet 42, the water-in-oil droplet 42 includes bamboo ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com