A Heparin Sodium Wastewater Treatment Process for Recovering Protein

A waste water treatment and heparin sodium technology, which is applied in the field of protein recovery process, can solve the problems of difficult waste water treatment, high content, waste of protein, etc., and achieve the effects of reducing the amount of hanging on the wall, improving the recovery rate, and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of heparin sodium wastewater treatment process of the present invention reclaims protein, comprises the following steps:

[0034] S1. Obtain heparin sodium wastewater, adjust the pH value of the wastewater to 7-8, and use a dynamic resin adsorption column to adsorb the wastewater to obtain a filtrate;

[0035] S2. Reduce the temperature of the filtrate to 10-20°C, add ethanol to the filtrate, and stir continuously until precipitation occurs, then slowly heat up to 30-40°C after precipitation, keep warm for 20-40 minutes, and filter to obtain the first clear liquid, crude protein;

[0036] S3. Adjust the pH of the first clear liquid to 8-10, add aluminum trichloride solution to the first clear liquid, add flocculant after stirring, react for 30-60min under the condition of stirring, then turn off the stirring and let stand for stratification ;

[0037] S4. Centrifuging the supernatant after standing and stratifying, the separated solid is crude protein, and coll...

Embodiment 2

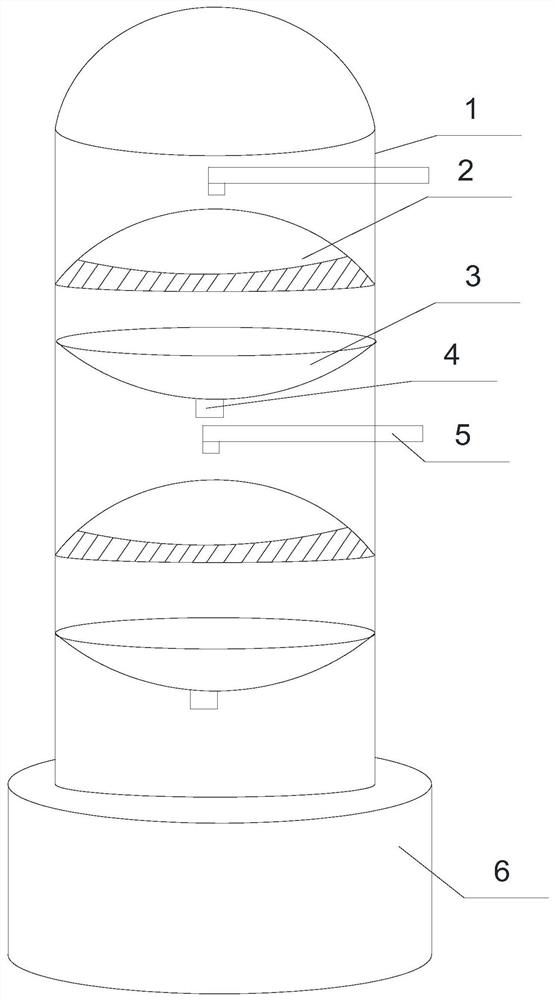

[0044] Based on Example 1, such as figure 1 As shown, the dynamic resin adsorption column includes a vertically placed cylinder 1, a plurality of arc-shaped covers 2 are arranged inside the cylinder 1, the arc-shaped covers 2 are hollow hemispheres, and the arc-shaped covers 2 Curved upwards, each arc-shaped cover body 2 is provided with a diversion groove 3, the diversion groove 3 is a hollow hemisphere bent downward, and the arc-shaped cover body 2, diversion groove 3 and cylindrical tube 1 are all Cut and tightly connected, the inside of the cylinder 1 between the arc-shaped cover body 2 and the diversion groove 3 is filled with resin, and the resin is compacted between the arc-shaped cover body 2 and the diversion groove 3 to form a resin column, and the arc-shaped cover The side wall near the bottom of the body 2 is a hollow wall, and the bottom of the diversion groove 3 is provided with a connecting pipe 4 communicating with the interior of the diversion groove 3. The co...

Embodiment 3

[0047] Based on the above-mentioned embodiment, a horizontally placed liquid inlet pipe 5 is arranged above each arc-shaped cover body 2, the liquid inlet of the liquid inlet pipe 5 is located outside the cylinder 1, and the liquid outlet of the liquid inlet pipe 5 is located on the cylinder 1 Inside, the liquid outlet of the liquid inlet pipe 5 is bent downward to form a straight pipe section, and the liquid outlet of the liquid inlet pipe 5 is coaxial with the arc-shaped cover body 2 . The bottom of the cylinder 1 is provided with a waste liquid cylinder 6 communicating with the cylinder 1 , and the liquid inlet ends of all the liquid inlet pipes 5 are connected with the waste liquid cylinder 6 .

[0048] The closer the resin column is to the top of the cylinder, the easier it is to reach saturation. Once the resin column reaches saturation, it cannot continue to absorb heparin sodium in the waste water; Repeated adsorption. After the waste liquid passes through the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com