Bacillus amyloliquefaciens q4 strain with high production of α-glucosidase inhibitor, functional rice wine and preparation method

A technology of glycosidase inhibitors and amylolytic spores, which is applied in the field of Bacillus amyloliquefaciens Q4 strain and functional rice wine and preparation, can solve the problems of mismatching of alcoholic fermentation speed and process of aroma production of rice wine, increase of fermentable sugar, and achieve Significant health care function, increase yield, and enrich the effect of wine body and mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

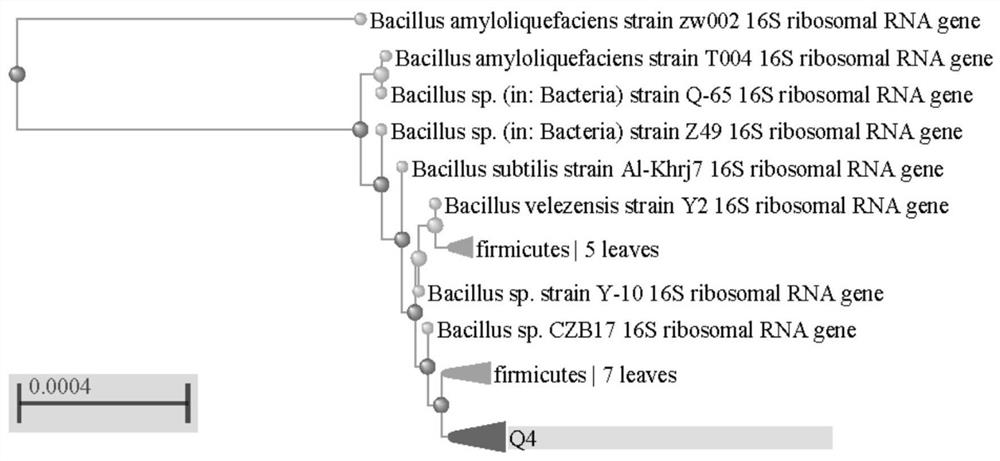

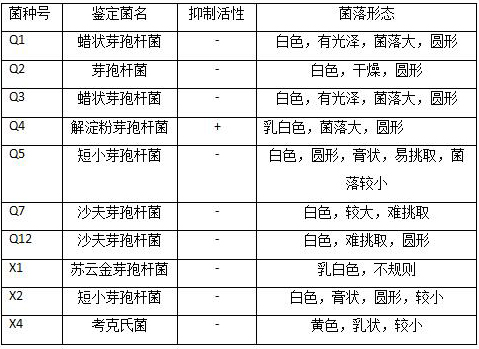

[0032] Example 1 Isolation and Identification of Bacillus with α-Glucosidase Inhibitory Activity

[0033] (1) Strain screening

[0034] Take several parts of distiller's yeast and raw materials from the Qufang of Laohenghe Company, suspend them with appropriate amount of sterile water, shake and disperse them, heat them in a water bath at 60°C for 30 minutes, and dissolve them in a mixture containing 2% glucose, 1.5% peptone, and 0.5% sodium chloride. , 0.5% beef extract and 2% agar solid medium plates were streaked. The plates were cultured at 37°C for 3 days, and the repurified aerobic bacterial colonies were stored on the solid medium slant as above.

[0035] (2) Identification of strains

[0036]The SK8225 kit was used to extract the genome of the isolated species, and the 7F primer (CAGAGTTTGATCCTGGCT) and the 1540R primer (AGGAGGTGATCCAGCCGCA) were used for PCR amplification, and then the gene comparison of the amplified products was used to identify the species.

[0...

Embodiment 2

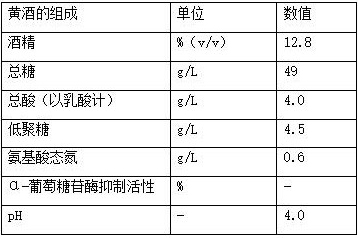

[0072] Example 2 Fermentation and production of mixed koji functional rice wine by using Q4 strains

[0073] Take 150kg of rice, add it to the rice soaking tank and keep submerged in clean water for 10-24 hours, and finish soaking the rice when the rice grains absorb water until there is no hard core; add the soaked rice to the rice steamer, and steam until the rice grains are hard on the outside and soft on the inside. Baixin finishes steaming rice and enters the fermentation process; after cooling down to 28°C with water, add 0.5% distiller's koji and 0.2% bacterial bran koji, mix well, add to the fermentation tank, build a nest for 36 hours and mix in 10kg of wheat koji to start fermentation , After 30 days of fermentation, the product functional rice wine is obtained after pressing, clarifying and decocting the wine. The composition analysis results are shown in the following table, wherein the α-glucosidase inhibitory activity and the content of oligosaccharides with prob...

Embodiment 3

[0076] The fermentative production of the conventional rice wine of embodiment 3 (control group)

[0077] Take 150kg of rice, add it to the rice soaking tank and keep submerged in clean water for 10-24 hours, and finish soaking the rice when the rice grains absorb water until there is no hard core; add the soaked rice to the rice steamer, and steam until the rice grains are hard on the outside and soft on the inside. Baixin finished steaming rice and entered the fermentation process; poured water to cool to 28°C, then added 0.5% distiller's koji, mixed well and then added to the fermentation tank, nested and saccharified for 36 hours, mixed with 10kg of wheat koji to start fermentation, after 30 days of fermentation, it was squeezed, After clarifying and decocting the wine, the product rice wine is obtained.

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com