Titanium and alloy of titanium with bone promoting effect as well as preparation method and application of titanium and alloy of titanium

A technology of titanium alloys and alloy materials, which is applied in the field of surface modification of titanium and its alloy materials and its preparation, can solve the problems of poor bone tissue integration and poor bone performance, and achieve the advantages of cell adhesion, osteoinductive ability, and The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Pure titanium whose length, width, and height are 10mm, 10mm, and 1mm, respectively, are treated with mixed acid (HF: HNO 3 :H 2 (0=1:5:34) and ultrasonic cleaning with deionized water twice, each time for 8 minutes. Mg in hydrothermal medium 2+ with Fe 3+ The total concentration is 0.05mol / L, where c(Mg 2+ ): c(Fe 3+ )=4:1, the titration solution is a mixed solution of sodium hydroxide and sodium bicarbonate, and c(NaOH):c(NaHCO 3 )=3:1, c(NaHCO 3 )=1mol / L, the pH value of the solution after titration is 9.5, and the stirring time is 30 minutes. The pH value of the solution after titration is 9.5. The aging time is 2 hours. The time is 16 hours, and the filling degree of the reactor is 33.33%.

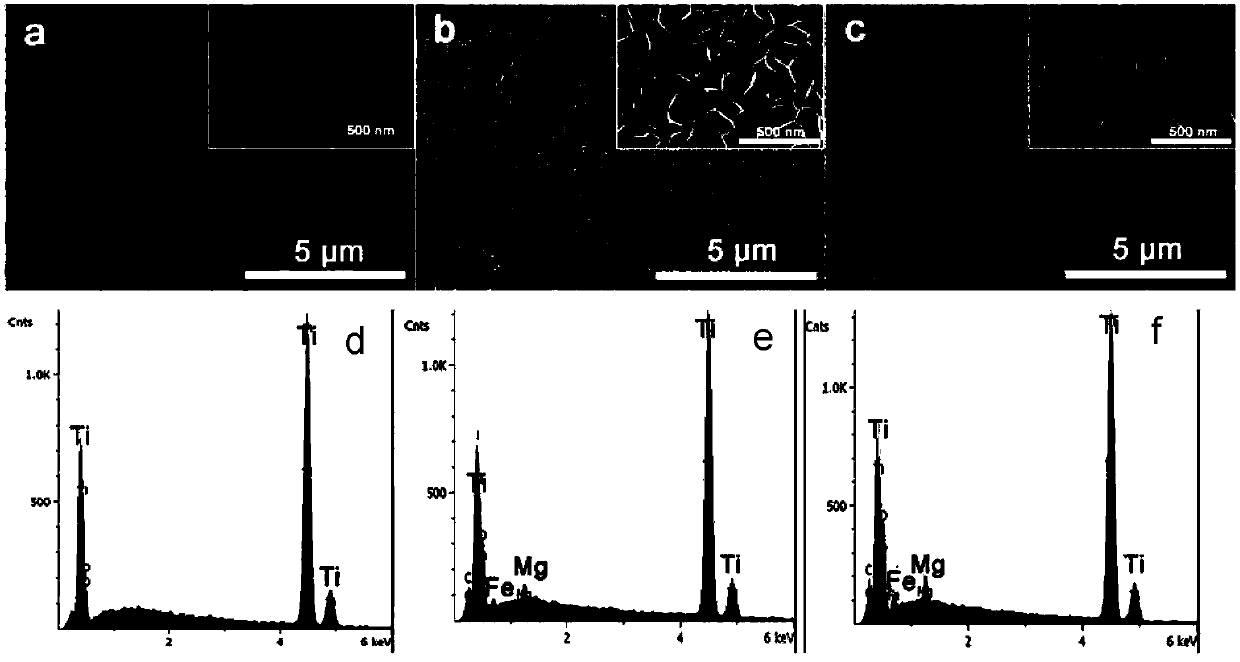

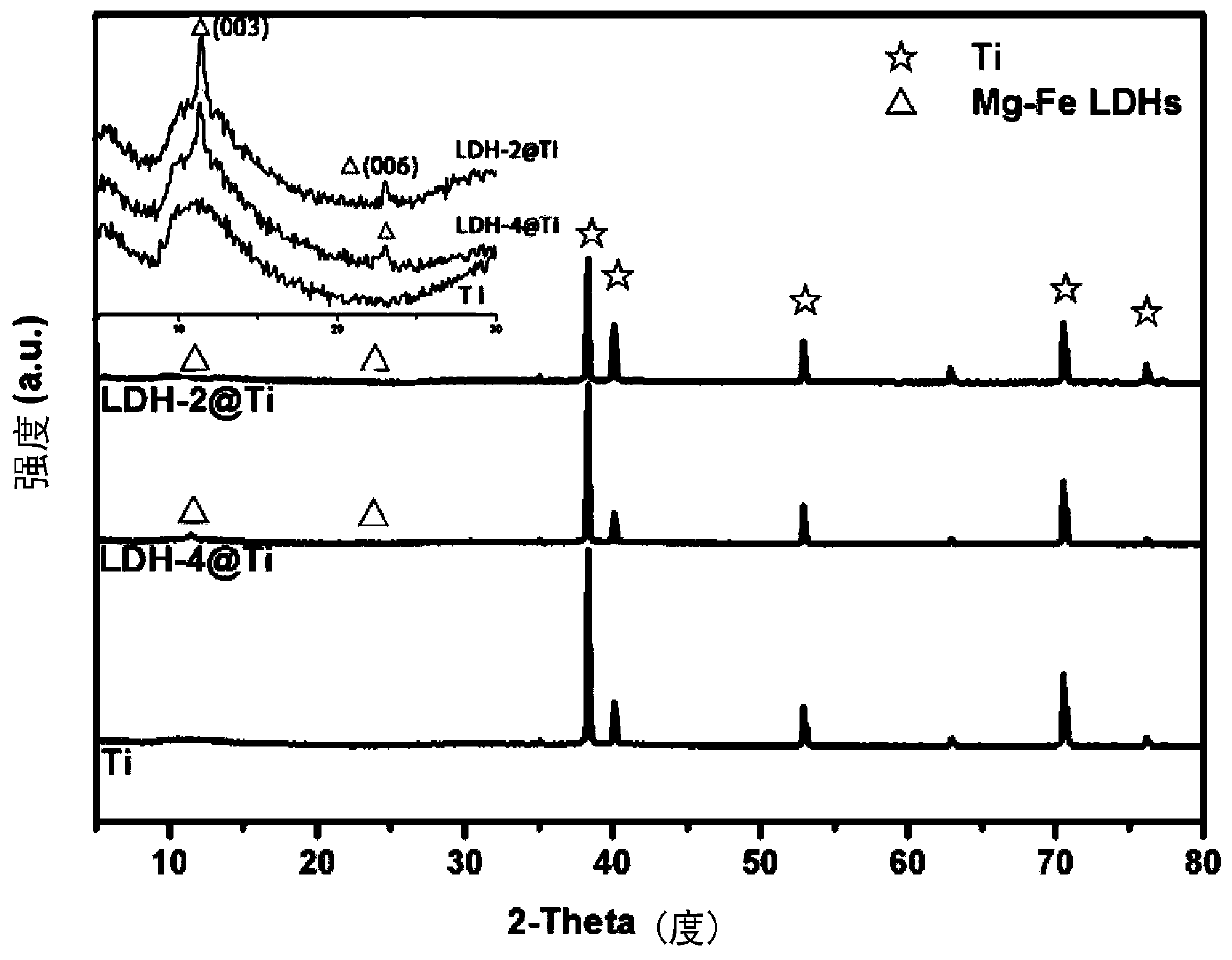

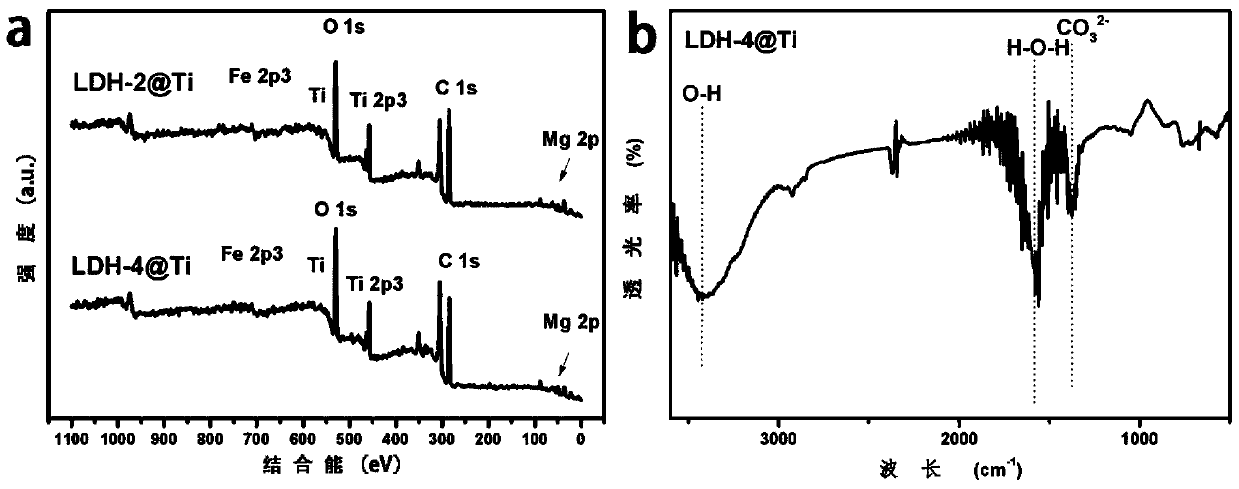

[0051] figure 1 (b, e) are the scanning electron micrographs and EDS spectra of the samples obtained through modification in this embodiment. It can be seen from the figure that the treated surface is a sheet-like nanostructure, and Mg and Fe elements exist on the surf...

Embodiment 2

[0053] Pure titanium whose length, width, and height are 10mm, 10mm, and 1mm, respectively, are treated with mixed acid (HF: HNO 3 :H 2 (0=1:5:34) and ultrasonic cleaning with deionized water twice, each time for 8 minutes. Mg in hydrothermal medium 2+ with Fe 3+ The total concentration is 0.05mol / L, where c(Mg 2+ ): c(Fe 3+ )=2:1, the titration solution is a mixed solution of sodium hydroxide and sodium bicarbonate, and c(NaOH):(NaHCO 3 )=3:1, c(NaHCO 3 )=1mol / L, the pH value of the solution after titration was 9.5, and the stirring time was 30 minutes. The pH value of the solution after titration was 9.5. The aging time was 2 hours. After 16 hours, the filling degree of the reactor was 33.33%.

[0054] figure 1(c, f) are the scanning electron micrographs and EDS spectra of the samples obtained through modification in this embodiment. It can be seen from the figure that the surface of the treated titanium sheet has a sheet-like nanostructure, and the distribution is ...

Embodiment 3

[0056] The modified samples obtained in Example 1 and Example 2 were subjected to an ion release test. The test sample was soaked in 10% PBS solution for 1 day, 4 days, 7 days, 14 days, 21 days and 28 days. Spectroscopy (ICP-AES) was used to test the release of magnesium ions and iron ions when the material was soaked for different times.

[0057] Figure 5 A and b in the figure respectively show the pattern of the release of magnesium ions and iron ions as a function of immersion time of the samples after the modified treatment of the present invention soaked in 10% PBS solution for different times. The modified film will be hydrolyzed in a liquid environment, thereby releasing metal ions. As can be seen from the figure, the modified samples obtained in Example 1 and Example 2 soaked for different times released Mg 2+ There was no significant difference in the amount of Fe 3+ There was no significant difference in the amount of .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com