A novel photoluminescence transparent glass-ceramic and its preparation method

A transparent glass and photoluminescence technology, applied in the field of transparent glass ceramics and its preparation, can solve the problems of low surface emission and spatial resolution, difficult to use in tiny devices, etc. Good stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

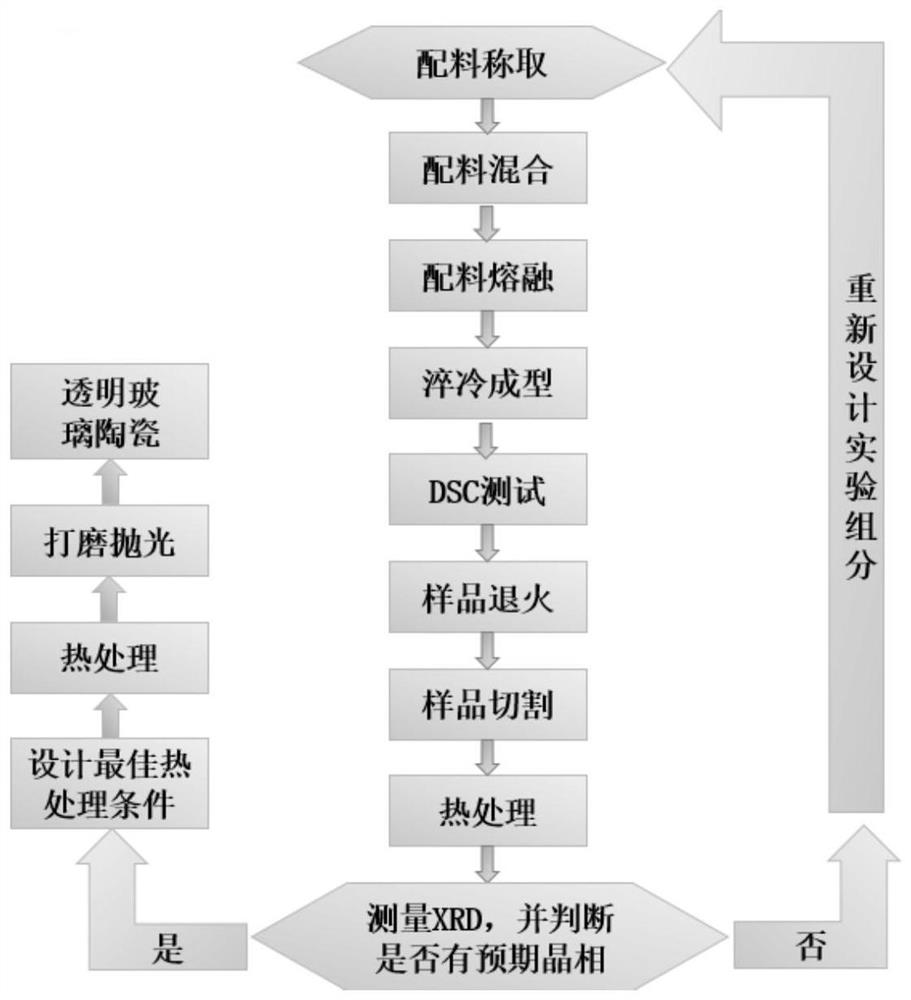

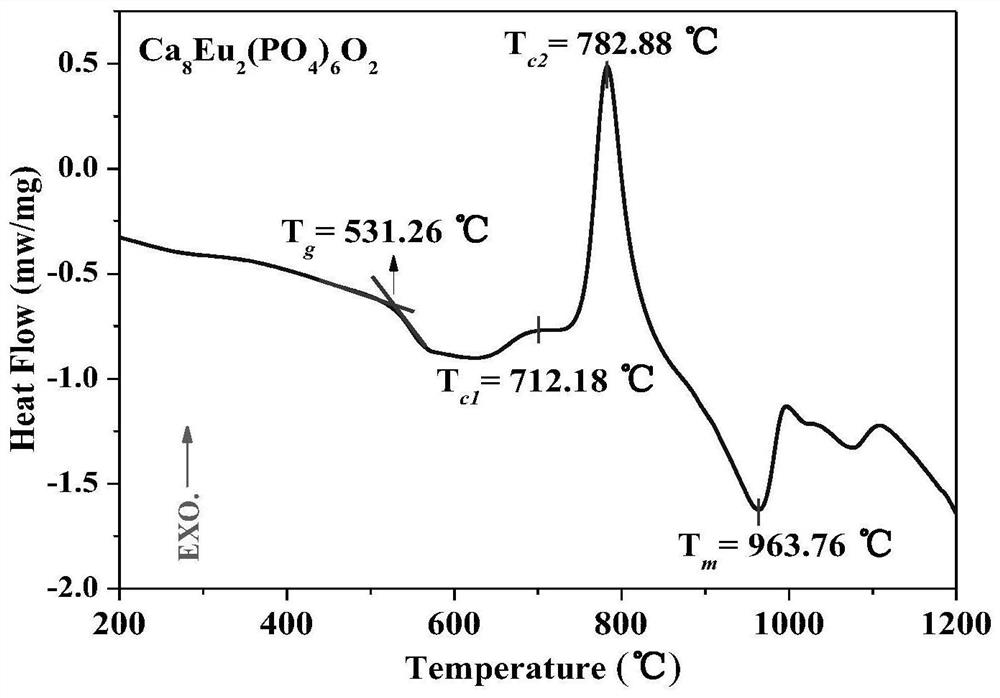

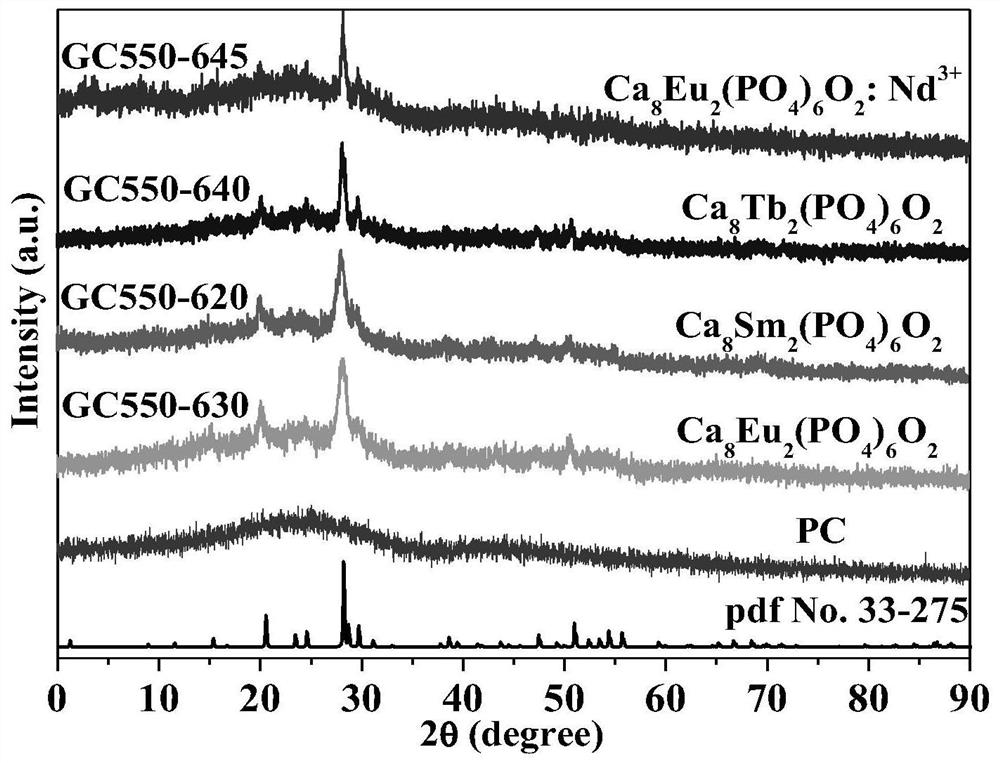

[0029] according to figure 1The experimental flow chart shown in the preparation of the proposed novel photoluminescent Ca of the present invention 8 Eu 2 (PO 4 ) 6 o 2 glass ceramics,

[0030] Step 1, weighing ingredients: calculate and weigh raw materials required for preparing transparent glass ceramics according to the following proportions. The mole percentage is: Na 2 CO 3 25%, CaO 23%, P 2 o 5 6%, H 3 BO 3 44%, Eu 2 o 3 2%, ZrO 2 As a crystal nucleating agent, it is weighed as 1% of the total weight of the batching.

[0031] Step 2, mixing ingredients: Put the raw materials weighed in step 1 into a pre-cleaned ceramic mortar, grind them thoroughly for 1 hour, mix the raw materials evenly, and obtain the batching materials, and put the batching materials in the pre-cleaned ceramic mortar in the crucible.

[0032] Step 3, ingredients melting: Put the ingredients in step 2 into a high-temperature lifting furnace to melt, the melting temperature is 1400°...

example 2

[0041] according to figure 1 The experimental flow diagram shown in the preparation of the proposed novel Ca-containing 8 SM 2 (PO 4 ) 6 o 2 Nanocrystalline photoluminescent glass ceramics,

[0042] Step 1, weighing ingredients: calculate and weigh raw materials required for preparing transparent glass ceramics according to the following proportions. The mole percentage is: Na 2 CO 3 25%, CaO 23.5%, P 2 o 5 6%, H 3 BO 3 44%, Sm 2 o 3 1.5%, ZrO 2 As a crystal nucleating agent, it is weighed as 1% of the total weight of the batching.

[0043] Step 2, mixing ingredients: Put the raw materials weighed in step 1 into a pre-cleaned ceramic mortar, grind them thoroughly for 1 hour, mix the raw materials evenly, and obtain the batching materials, and put the batching materials in the pre-cleaned ceramic mortar in the crucible.

[0044] Step 3, ingredients melting: put the ingredients in step 2 into a high-temperature lifting furnace to melt, the melting temperature...

example 3

[0053] according to figure 1 The experimental flow diagram shown in the preparation of the proposed novel Ca-containing 8 Tb 2 (PO 4 ) 6 o 2 Nanocrystalline photoluminescent glass ceramics,

[0054] Step 1, weighing ingredients: calculate and weigh raw materials required for preparing transparent glass ceramics according to the following proportions. The mole percentage is: Na 2 CO 3 25%, CaO 22%, P 2 o 5 6%, H 3 BO 3 44%, Tb 4 o 7 3%, ZrO 2 As a crystal nucleating agent, it is weighed as 1% of the total weight of the batching.

[0055] Step 2, mixing ingredients: Put the raw materials weighed in step 1 into a pre-cleaned ceramic mortar, grind them thoroughly for 1 hour, mix the raw materials evenly, and obtain the batching materials, and put the batching materials in the pre-cleaned ceramic mortar in the crucible;

[0056] Step 3, ingredients melting: Put the ingredients in step 2 into a high-temperature lifting furnace to melt, the melting temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com