Method for preparation of high performance and multifunctional shape memory material

A memory material and multi-functional technology, applied in the field of materials science, can solve problems such as rarely reported methods, achieve broad industrialization and market application prospects, high application value, and improve the effect of shape memory performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

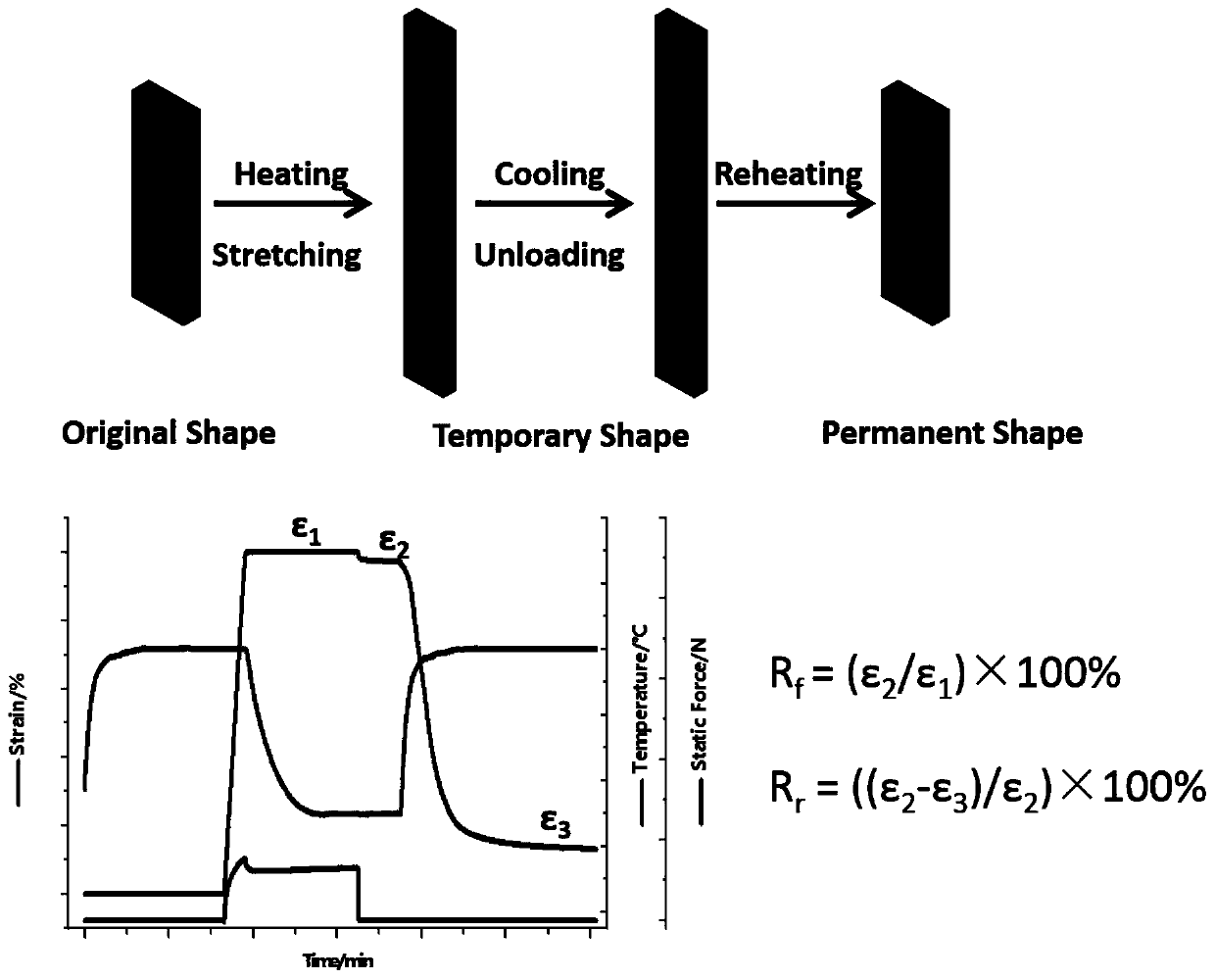

[0034] (1) The crystalline / amorphous polymer composite system is the research object, and the typical polycrystalline semi-crystalline polymer polyvinylidene fluoride (PVDF) and the amorphous polymer with good compatibility and strong molecular chain interaction are selected. Polymethyl methacrylate (PMMA) was used as the raw material, and the raw material was dried in a vacuum oven at 80°C for 12 hours to remove moisture before use;

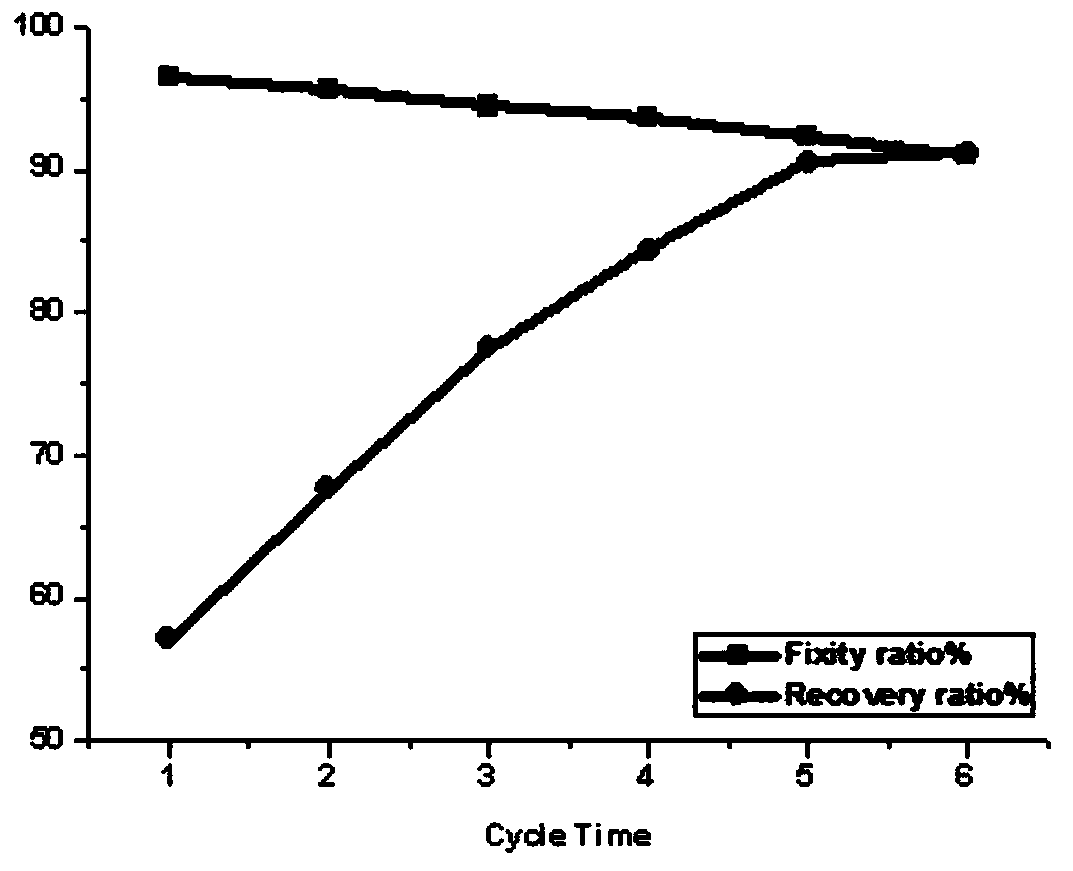

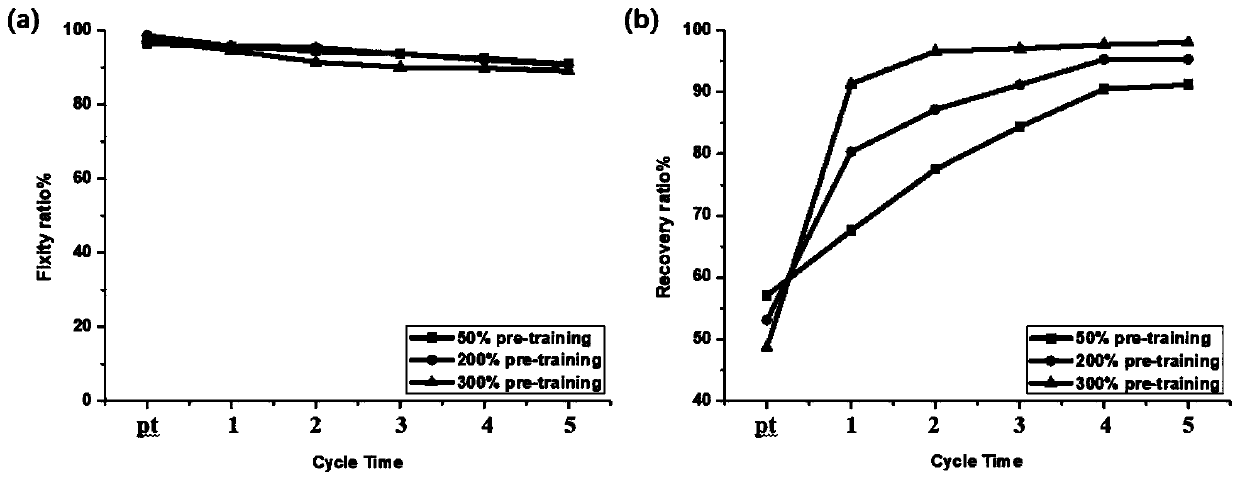

[0035] (2) PVDF and PMMA were melt-mixed by an internal mixer at 200°C, and then pressed into a composite sheet at the same temperature. The shape memory properties of PVDF, PMMA and their blends were tested by DMA and the corresponding R f and R r . When the test temperature is 80°C and the deformation is 50%, the R of each sample f and R r They are:

[0036] PVDF 2 / 1 1 / 1 PMMA Fixed rate (R f ), %

90.2 96.4 97.4 99.9 Response rate (R r ), %

43.5 57.1 68.2 37.1

[0037]In the table, 2 / 1 means t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com