Efficient photo-thermal conversion material with roll-like structure as well as preparation method and application thereof

A photothermal conversion and photothermal technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc., can solve problems such as difficulty in expansion and restriction, and achieve the effect of improving absorption and capture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

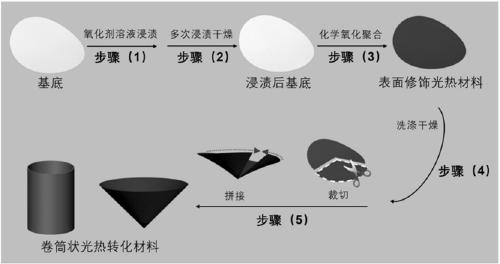

[0041] Depend on figure 1 Shown:

[0042] (1) Immerse a circular hydrophilic polyvinylidene fluoride (PVDF) membrane with a diameter of 50 mm to a concentration of 0.2 mol L -1 Ammonium persulfate aqueous solution, standing at room temperature for 12 hours. Take out the impregnated PVDF membrane and dry it naturally.

[0043] (2) Repeat the dipping-drying operation of step (1) twice.

[0044] (3) Take 10 μL of pyrrole and place it in a container, and seal the treated PVDF membrane obtained in step (2) together in the container. Incubate at 70°C for 60min. The amount of pyrrole is equivalent to 0.5 μL corresponding to the surface area of the substrate material per square centimeter

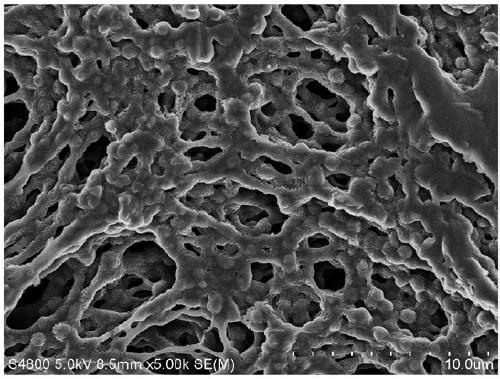

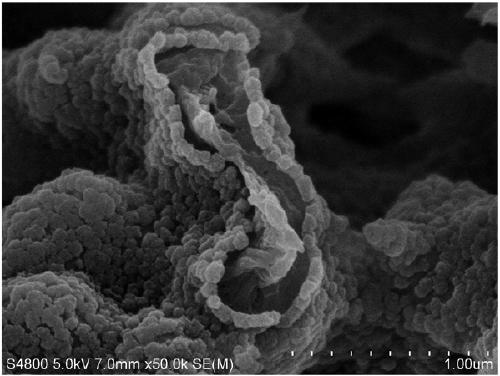

[0045] (4) Wash the surface-modified membrane material obtained in step (3) with deionized water and ethanol in turn until the washing solution is colorless, and then dry it naturally (see figure 2 and 3 ). Depend on figure 2 , 3 The surface morphology and cross-section of the polymer a...

Embodiment 2

[0049] The difference from Example 1 is:

[0050] Replace the base material in step (1) with carbon cloth, carbon paper, non-woven fabric, dust-free paper, cotton cloth, gauze, nickel foam, polycarbonate (PC) membrane, polysulfone (PSF) membrane, polyethersulfone (PES) film, cellulose acetate film, mixed cellulose ester film (MCE), polyamide (PA) film, polyacrylonitrile (PAN) film; and then respectively obtain roll-shaped photothermal materials from the above base materials.

Embodiment 3

[0052] The difference from Example 1 is:

[0053] Set the substrate size in step (1) to a circle of 5mm, 10mm, 20mm, 100mm, 200mm, and 500mm, respectively. The size is a rectangle of 5mm × 5mm, 10mm × 10mm, 20mm × 20mm, 100mm × 100mm, 200mm × 100mm, 500mm × 100mm, and is directly crimped into a hollow cylinder in step (5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com