A kind of high-performance hydrophilic non-stick dust coating and preparation method thereof

A high-performance, dust-sticking technology, applied in coatings, analytical materials, material inspection products, etc., can solve the problems of low photocatalytic efficiency, short non-stick layer duration, poor non-stick dust effect of coatings, etc., to achieve Enhance photocatalysis, improve coating hydrophilicity, improve the effect of non-stick dust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-performance hydrophilic non-stick coating formulation:

[0039] Table 1 Embodiment 1 formula

[0040]

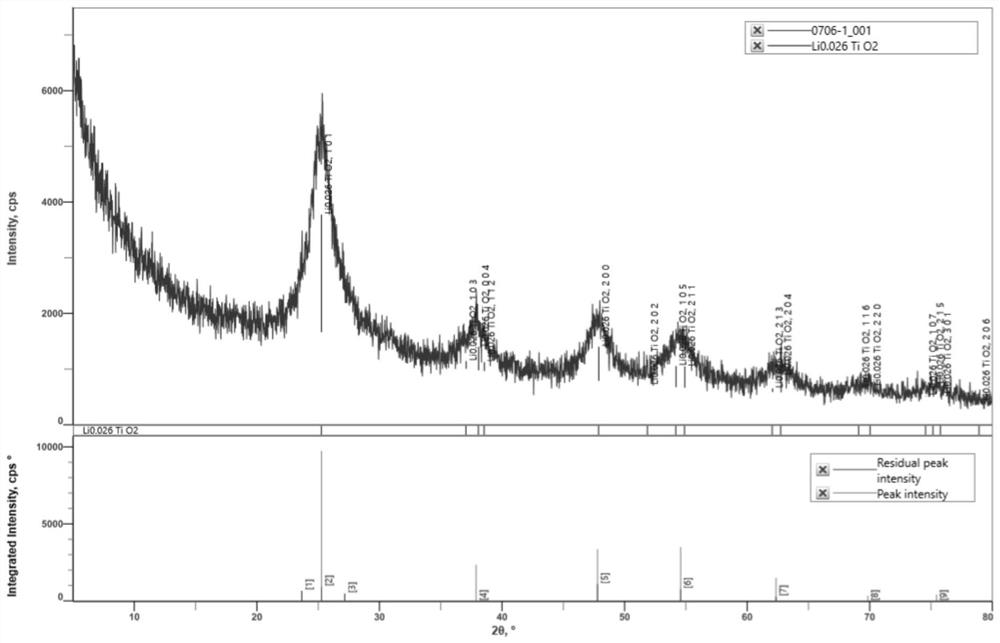

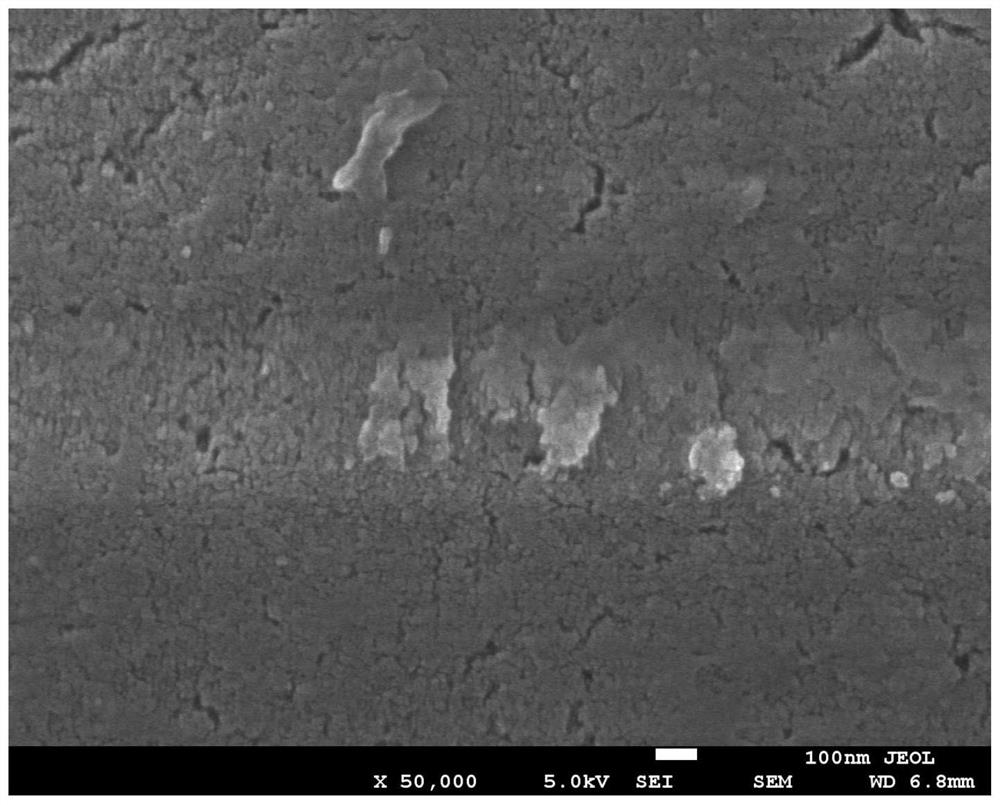

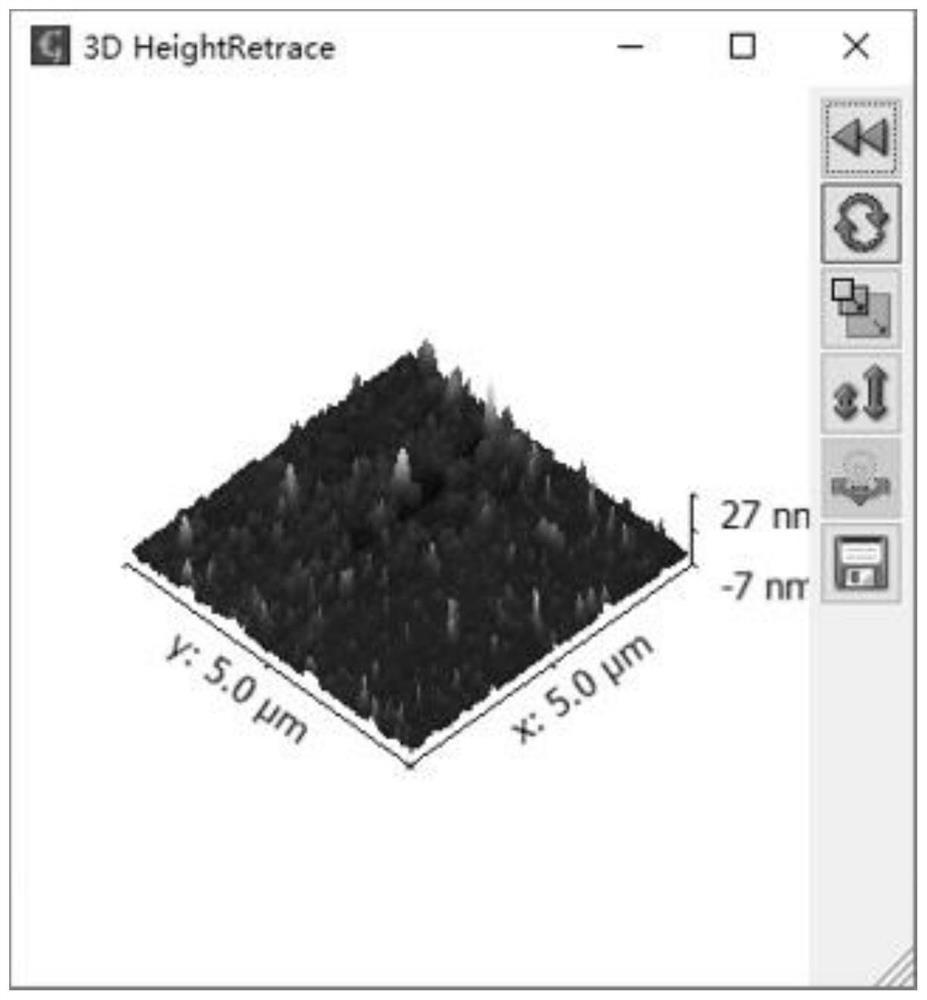

[0041] A high-performance hydrophilic non-stick dust coating, which is a high-performance non-stick dust hydrophilic coating that can be used on wood, metal and plastic surfaces. In this coating, tetrabutyl titanate is hydrolyzed into titanium sol, which is dispersed in ethanol solution Among them, the preparation process of titanium sol: 75.82 g of absolute ethanol, 1.66 g of tetrabutyl titanate, and 1.3 g of nitric acid were sequentially added into a four-neck flask, and stirred at 70° C. for 1 h to disperse the raw materials evenly. Disperse 4g of deionized water in 15g of absolute ethanol, add dropwise into a four-necked flask, stir and react at 70°C for 3h, control the reaction conditions, and hydrolyze tetrabutyl titanate into a titanium sol with an average particle size of about 150nm .

[0042] After the required titanium sol was obtained, it was t...

Embodiment 2

[0054] A high-performance hydrophilic non-stick coating formulation:

[0055] Table 4 Example 2 formula

[0056]

[0057] Titanium sol preparation process: 76.36 g of absolute ethanol, 1.92 g of isopropyl titanate, and 1.5 g of nitric acid were sequentially added into a four-neck flask, and stirred at 70° C. for 1 h to disperse the raw materials evenly. Disperse 4g of deionized water in 15g of absolute ethanol, add dropwise into a four-necked flask, stir and react at 70°C for 3h, and hydrolyze isopropyl titanate into a titanium sol with an average particle size of about 120nm.

[0058] After the required titanium sol is prepared, take it out and cool it to room temperature, add 0.12g of tungsten trioxide, 0.5g of acetylacetone, 0.1g of polyether modified silicone DEGO-245 and 0.5g of propylene glycol monomethyl ether, and stir at room temperature for 1 hour , filter package. Coating performance: the appearance is light blue and transparent, the viscosity is about 1mPa·s, ...

Embodiment 3

[0064] A high-performance hydrophilic non-stick coating formulation:

[0065] Table 6 Example 3 formula

[0066]

[0067] The preparation process of titanium sol: Add 75.24 g of absolute ethanol, 1.66 g of tetrabutyl titanate, and 1.5 g of hydrochloric acid in sequence in a four-neck flask, and stir at 70° C. for 1 hour to disperse the raw materials evenly. Disperse 5 g of deionized water in 15 g of absolute ethanol, add it dropwise into a four-necked flask, stir and react at 70° C. for 3 h, and hydrolyze tetrabutyl titanate into a titanium sol with an average particle diameter of about 150 nm.

[0068] After obtaining the required titanium sol, take it out and cool to room temperature, add 0.2g ZrO 2 ,0.1gAg 3 PO 4 and 0.2SnWO 4 , 0.2g V 2 o 5 and 0.3gBi 2 S 3 , and added 0.5g diethanolamine, 0.1g polyether modified silicone DC-67 and 0.5g propylene glycol monobutyl ether, stirred at room temperature for 1 hour, filtered and packaged.

[0069] Coating performance:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com