A kind of super wear-resistant super amphiphobic coating and its preparation method and application

A super-amphiphobic and super-abrasion-resistant technology, applied in coatings, powder coatings, polyester coatings, etc., can solve the problems of powder coatings with general wear resistance and no oleophobic properties, and achieve excellent ice-phobic properties, The effect of reducing the adhesion of the ice layer and speeding up the solidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, common commercially available polyester powder coatings are used.

[0041] (1) Preparation of existing powder coating: uniformly spray the existing polyester powder coating on the aluminum alloy substrate by electrostatic spraying, the input voltage is 220V, the electrostatic output voltage of the spray gun is 100KV, the powder supply pressure is 0.5MPa, and the spraying distance 200mm.

[0042] (2) Resin hot-melt curing: place the painted sample in an oven at 220°C and heat for 10 minutes, so that the resin powder in the coating is fully melted and cured, and the existing powder coating can be obtained.

[0043] The coating sample prepared in Example 1 was tested, and the cross-hatch test adhesion results showed that the paint film adhesion was first grade, and other test results are shown in the table below.

[0044] Table of performance data of coated samples and their wear after different cycles

[0045]

Embodiment 2

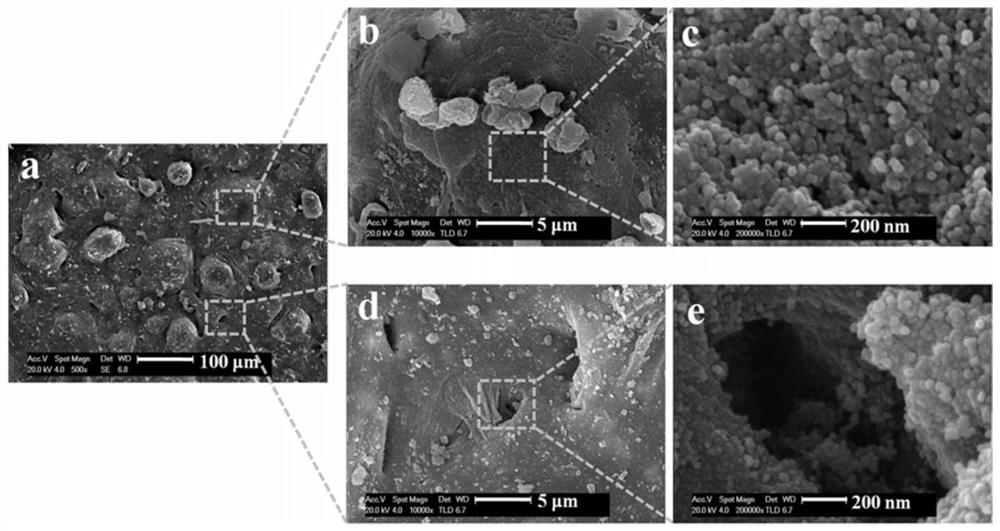

[0047] In this embodiment, the resin powder is epoxy resin powder used for electrostatic plastic spraying, and the particle size of the resin powder is 200 nm˜2 μm. The hydrophobic powder is hydrophobic silicon dioxide powder, and the particle size of the hydrophobic powder is 1-50 μm. The preparation method of the hydrophobic silica is as follows: firstly, disperse 3g of water-based silica sol in 16mL of aqueous solution, add 4mL of 1vt.% ammonia water for alkalization; then add the above solution into 80mL of ethanol solution, mix well and then add 0.6mL Heptadecafluorodecyltrimethoxysilane was used for hydrophobic modification of the surface. After mechanical stirring and natural standing for 24 hours, it was dried at 80°C, pulverized by a crusher, and then passed through a 200-mesh sieve to obtain hydrophobic silica powder.

[0048] A preparation method of an ultra-wear-resistant super-amphiphobic coating, comprising the following steps:

[0049] (1) Preparation of nano-s...

Embodiment 3

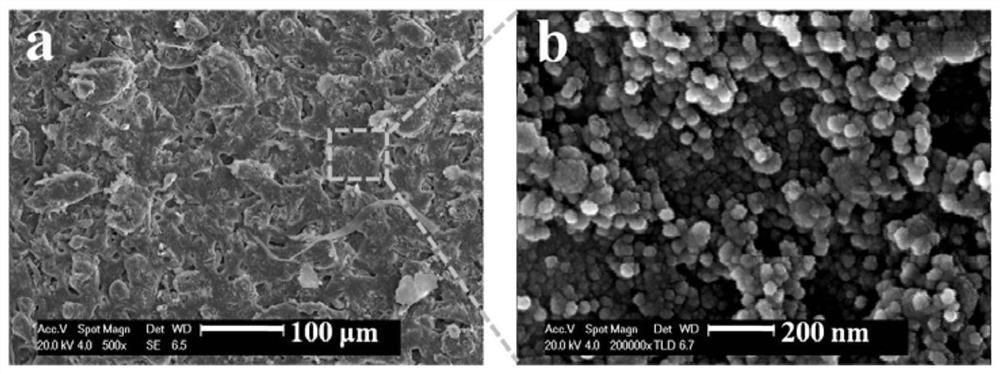

[0059] In this embodiment, the resin powder is a fluorocarbon resin powder used for electrostatic plastic spraying, and the particle size of the resin powder is 200 nm˜2 μm. The hydrophobic powder is hydrophobic silicon dioxide powder, and the particle size of the hydrophobic powder is 1-50 μm. The preparation method of the hydrophobic silica is as follows: firstly, disperse 3g of water-based silica sol in 16mL of aqueous solution, add 4mL of 1vt.% ammonia water for alkalization; then add the above solution into 80mL of ethanol solution, mix well and then add 0.6mL Heptadecafluorodecyltrimethoxysilane was used for hydrophobic modification of the surface. After mechanical stirring and natural standing for 24 hours, it was dried at 80°C, pulverized by a crusher, and then passed through a 200-mesh sieve to obtain hydrophobic silica powder.

[0060] A preparation method of an ultra-wear-resistant super-amphiphobic coating, comprising the following steps:

[0061] (1) Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com