Regeneration method for resin used for treatment on high-boiling residue wastewater

A technology of resin regeneration and high boiling substances, which is applied in separation methods, filter regeneration, special treatment targets, etc., can solve the problems of low regeneration rate, achieve the effect of increasing regeneration rate and reducing the difficulty of desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

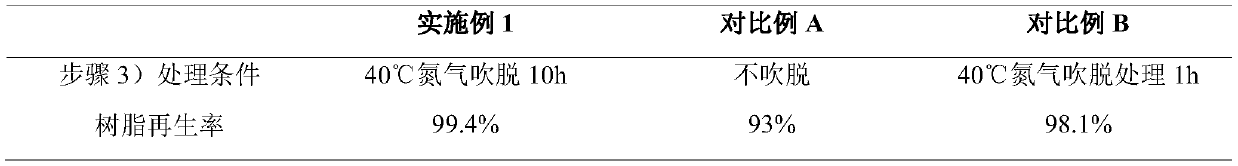

Examples

Embodiment 1

[0032] The wastewater produced by chlorinated cyanide has the characteristics of strong acidity, high concentration of organic matter, relatively stable physical and chemical properties of organic matter, and high boiling point of some organic matter, which can hardly be treated by conventional processes. For the treatment of such acidic waste water, activated carbon adsorption and resin adsorption are generally used. Technology, activated carbon adsorption technology has a better treatment effect, but it has disadvantages such as difficult regeneration, poor environment for adsorbent replacement, and high operating costs. One of the keys to resin adsorption technology is the desorption and regeneration ability of the resin. High boiling substances in wastewater often lead to It is difficult to completely desorb the problem, therefore, the present invention further improves the resin regeneration rate by improving the resin desorption efficiency; the waste water containing high ...

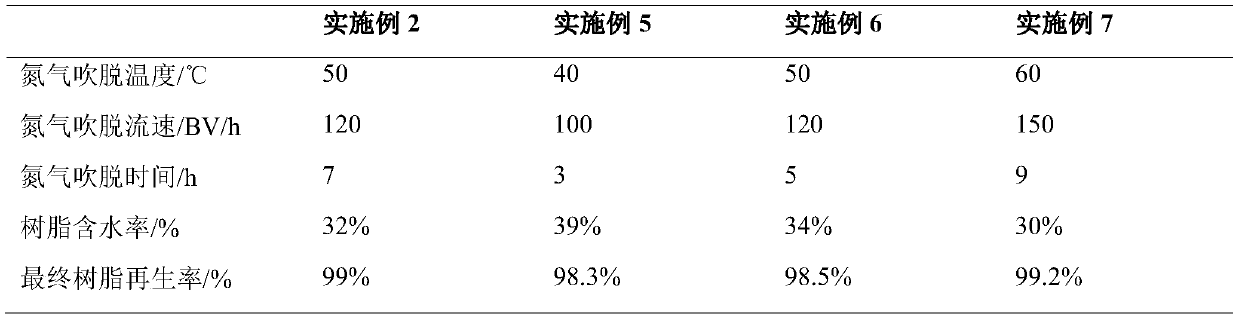

Embodiment 2

[0050] The waste water quality that adopts in the present embodiment is identical with embodiment 1, and the resin that is used for adsorption adopts the NDA-100 of Jiangsu Nanda Environmental Protection Technology Co., Ltd., and concrete treatment steps are as follows:

[0051] A kind of resin regeneration method for treating waste water containing high boilers of the present invention is realized by the following steps:

[0052] 1) Use a pump to pump the chlorinated bianium production wastewater in the water storage tank into the filter device at a certain flow rate and pass through the quartz sand filter filter system to remove mechanical impurities in the wastewater. The filter is regularly backwashed according to the water quality, and the backwash water After collection, it will be purified and treated by the bag filter system for the next backwash. The filter residue needs to be disposed of properly, and the filtered wastewater will enter the resin adsorption system for ...

Embodiment 3

[0059] The waste water quality that adopts in the present embodiment is identical with embodiment 1, and the resin that is used for adsorption adopts the NDA-100 of Jiangsu Nanda Environmental Protection Technology Co., Ltd., and concrete treatment steps are as follows:

[0060] A kind of resin regeneration method for treating waste water containing high boilers of the present invention is realized by the following steps:

[0061] 1) Use a pump to pump the chlorinated bianium production wastewater in the water storage tank into the filter device at a certain flow rate and pass through the quartz sand filter filter system to remove mechanical impurities in the wastewater. The filter is regularly backwashed according to the water quality, and the backwash water After collection, it will be purified and treated by the bag filter system for the next backwash. The filter residue needs to be disposed of properly, and the filtered wastewater will enter the resin adsorption system for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com