Preparation methods for walnut-shell grafted beta-cyclodextrin type catalyst and 2-amino-3-cyano-4H-pyran derivative

A technology of pyran derivatives and walnut shells, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as unsatisfactory catalysts and long reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific steps of this embodiment include two parts:

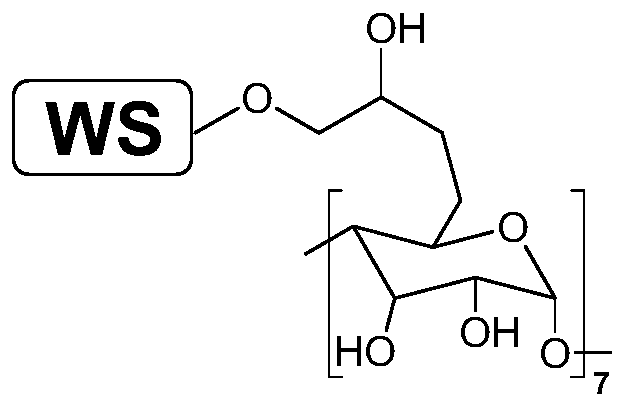

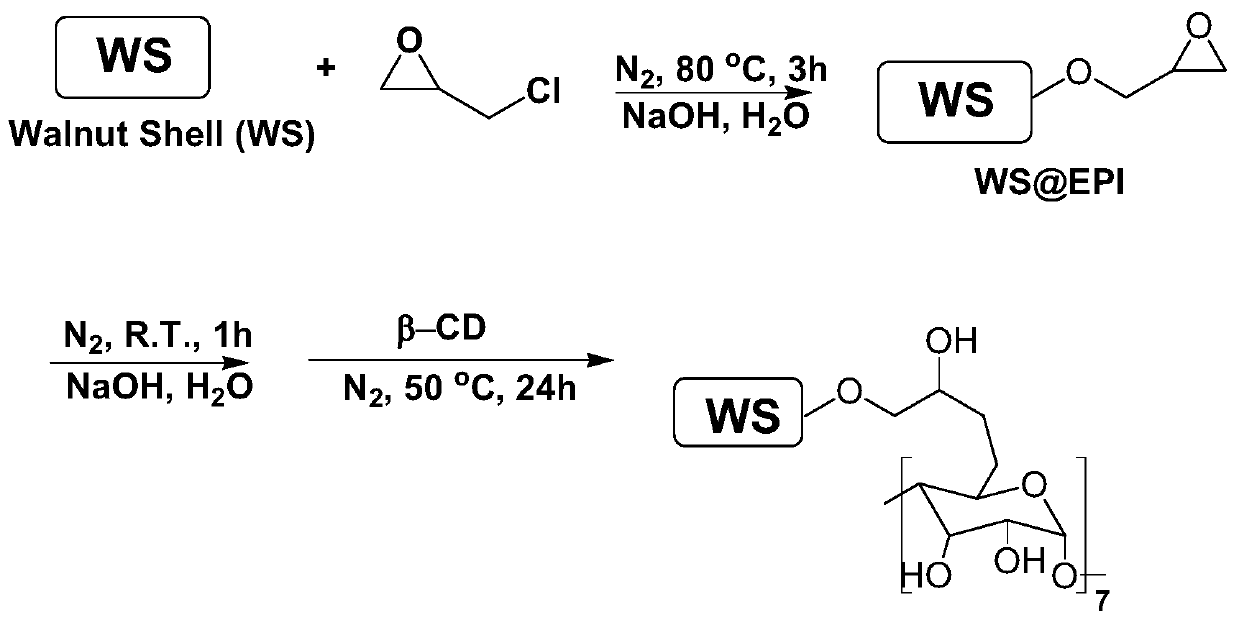

[0039] 1) Preparation of walnut shell grafted β-CD catalyst (WS@EPI / β-CD), the reaction route is as follows figure 2 :

[0040] 1) Put walnut shells, deionized water, sodium hydroxide and epichlorohydrin in the reaction bottle in turn, and then react for 3 hours in a nitrogen environment at 80°C; The volume dosage of sodium hydroxide is 4.8-5.0mL / g, the mass dosage of sodium hydroxide is 0.85-1g / g, and the volume dosage of epichlorohydrin is 1.8-2.0mL / g;

[0041] 2) After the reaction, the product in the reaction bottle was washed with water, centrifuged and dried to obtain epoxidized walnut shells, that is, WS@EPI;

[0042] 3) Add WS@EPI, deionized water and sodium hydroxide into the reaction bottle, and react at room temperature for 1 hour; among them, the volume of deionized water is 14-15mL / g based on the quality of WS@EPI , the mass dosage of sodium hydroxide is 2.8~3.0g / g;

[0043] 4) After the reacti...

Embodiment 2

[0050] The difference between Example 2 and Example 1 is: Step 2) is 2-amino-3-cyano-7,7-dimethyl-4-(4-chlorophenyl)-5-oxo-5,6 , the preparation of 7,8-4H-benzopyran (structural formula is as follows):

[0051]

[0052] Add 0.002mol of p-chlorobenzaldehyde, malononitrile and dimedone into the reaction flask, then add 2mL of ethanol and 50mg of catalyst WS@EPI / β-CD to the reaction flask in sequence, and quickly place the reaction flask in React in an oil bath at 60°C for 5 minutes. After the reaction is over, add a certain amount of water to the reaction flask to quench the reaction, and filter to obtain a solid product containing the catalyst; then dissolve the solid product with ethanol, and perform multiple centrifugation operations to separate the product from the catalyst. Finally, the centrifuged solution was subjected to a rotary evaporation operation to obtain a crude product, which was then recrystallized and dried to obtain 0.64 g of the target product with a yiel...

Embodiment 3

[0055] The difference between Example 3 and Example 1 is: Step 2) is 2-amino-3-cyano-7,7-dimethyl-4-(4-methoxyphenyl)-5-oxo-5 , the preparation of 6,7,8-4H-benzopyran (structural formula is as follows):

[0056]

[0057] Add 0.002mol of p-methoxybenzaldehyde, malononitrile and dimedone into the reaction flask, then add 2mL of ethanol and 50mg of catalyst WS@EPI / β-CD to the reaction flask in sequence, and quickly put the reaction flask Placed in an oil bath at 60°C for 8 minutes. After the reaction is over, add a certain amount of water to the reaction flask to quench the reaction, and filter to obtain a solid product containing the catalyst; then dissolve the solid product with ethanol, and perform multiple centrifugation operations to separate the product from the catalyst. Finally, the centrifuged solution was subjected to a rotary evaporation operation to obtain a crude product, which was then recrystallized and dried to obtain 0.62 g of the target product with a yield ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap