Alkaline soil conditioner for improving acidified soil

A soil conditioner, alkaline technology, applied in the direction of calcium superphosphate, fertilizer mixture, phosphate fertilizer, etc., can solve the problems that the inherent soil fertility effect of the soil cannot be fully exerted, the content of organic matter and nutrients is low, and cannot be fully resolved, so as to improve the absorption of crops High efficiency, long-lasting fertilizer effect, and remarkable regulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

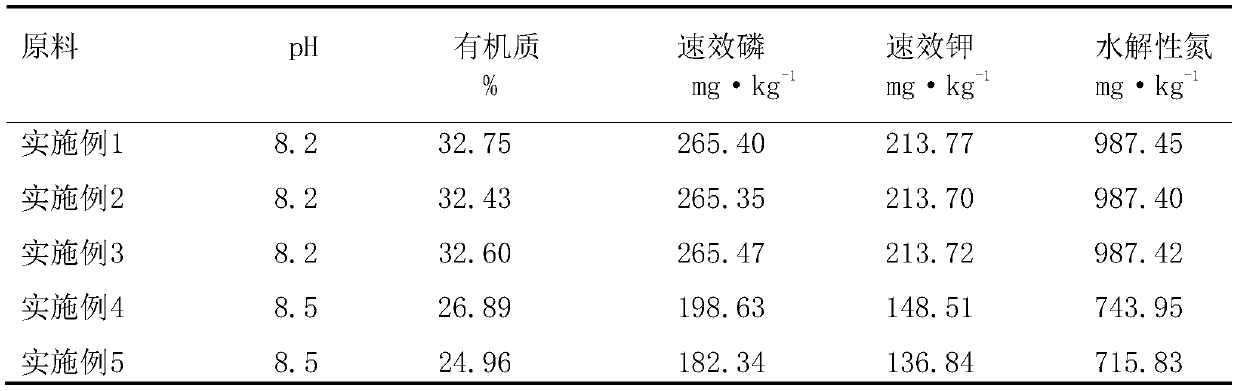

Embodiment 1

[0024] An alkaline soil conditioner for improving acidified soil, made of the following raw materials in parts by weight: 80 parts of dehydrated sheep manure, 50 parts of peat soil, 18 parts of corncob biochar, 15 parts of sphagnum moss, 25 parts of tea leaves, bone meal 40 parts, 8 parts of superphosphate, 7 parts of brucite powder, 6.5 parts of calcite powder, 12 parts of bentonite, 0.2 parts of compound bacteria solution, 150 parts of kelp water, 75 parts of rice washing water;

[0025] The preparation method of the corncob biochar is as follows: the corncob is pyrolytically carbonized in a pyrolysis carbonization furnace under anaerobic conditions, and stored in a desiccator after cooling, the pyrolysis temperature is 550°C, and the pyrolysis time is 1 hour; Then kelp water is soaked for 30 minutes, and then pyrolyzed at 850° C. for 1 hour to make corn cob biochar, wherein the added amount of kelp water is 20-25% of the weight of corn cob;

[0026] The kelp water is adjust...

Embodiment 2

[0036] An alkaline soil conditioner for improving acidified soil, made of the following raw materials in parts by weight: 50 parts of dehydrated sheep manure, 40 parts of peat soil, 12 parts of corncob biochar, peat moss 10 parts, 18 parts of tea leaves, 35 parts of bone meal, 6 parts of superphosphate, 5 parts of brucite powder, 5 parts of calcite powder, 8 parts of bentonite, 0.1 part of compound bacteria liquid, 150 parts of kelp water, 75 parts of rice washing water;

[0037] The preparation method of the corncob biochar is as follows: the corncob is pyrolytically carbonized in a pyrolysis carbonization furnace under anaerobic conditions, and stored in a desiccator after cooling, the pyrolysis temperature is 550°C, and the pyrolysis time is 1 hour; Then kelp water is soaked for 30 minutes, and then pyrolyzed at 850° C. for 1 hour to make corn cob biochar, wherein the added amount of kelp water is 20-25% of the weight of corn cob;

[0038] The kelp water is adjusted to a pH...

Embodiment 3

[0042] An alkaline soil conditioner for improving acidified soil, made of the following raw materials in parts by weight: 80 parts of dehydrated sheep manure, 60 parts of peat soil, 20 parts of corn cob biochar, peat moss 17 parts, 30 parts of tea leaves, 45 parts of bone meal, 9 parts of superphosphate, 7.5 parts of brucite powder, 8 parts of calcite powder, 15 parts of bentonite, 0.3 parts of compound bacteria liquid, 160 parts of kelp water, 80 parts of rice washing water;

[0043] The preparation method of the corncob biochar is as follows: the corncob is pyrolytically carbonized in a pyrolysis carbonization furnace under anaerobic conditions, and stored in a desiccator after cooling, the pyrolysis temperature is 550°C, and the pyrolysis time is 1 hour; Then kelp water is soaked for 30 minutes, and then pyrolyzed at 850° C. for 1 hour to make corn cob biochar, wherein the added amount of kelp water is 20-25% of the weight of corn cob;

[0044] The kelp water is adjusted to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com