Composite electrode, preparation method thereof, application of composite electrode and electro-catalysis complete hydrolysis device

A composite electrode and electrocatalysis technology, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of restricting the efficiency of electrocatalysis in total water splitting, slow reaction kinetics, and difficulty in large-scale application, and achieve high electron transfer efficiency, Strong ability to promote the effect of anode oxygen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

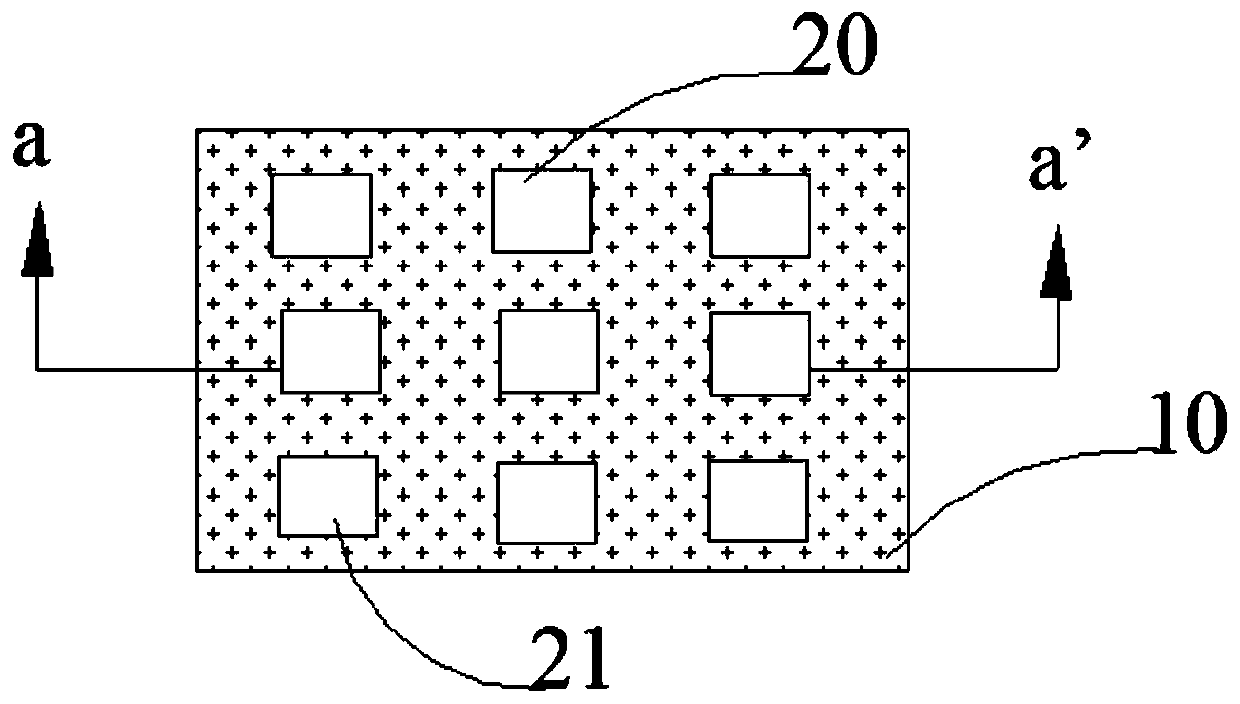

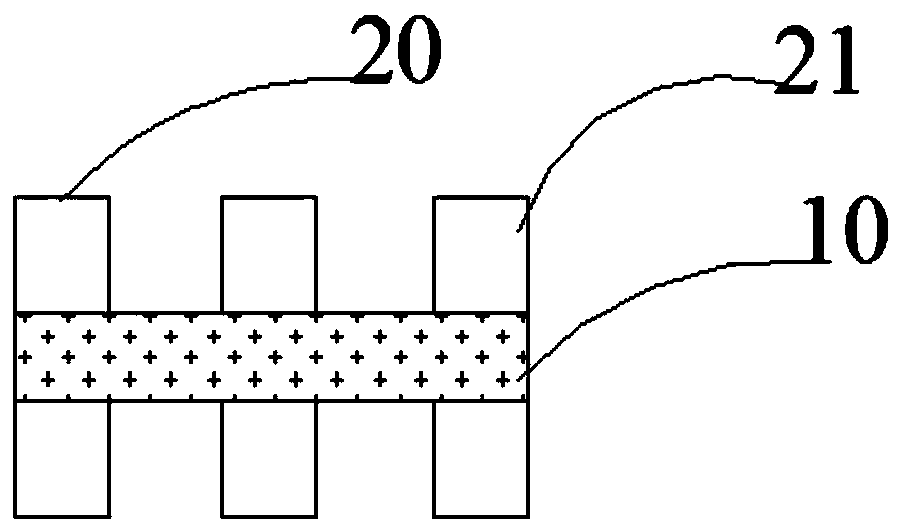

[0072] In another aspect of the present invention, the present invention provides a method for preparing the aforementioned composite electrode. The method includes:

[0073] S100: Form a first active material layer on at least part of the surface of the conductive substrate to obtain a composite layer.

[0074] It should be noted that the conductive matrix and the first active material layer are consistent with the previous description, and will not be repeated here.

[0075] In some embodiments of the present invention, the first active material layer is grown on the surface of the conductive substrate by first in-situ growth.

[0076] In some specific embodiments of the present invention, the first in-situ growth includes: coating the surface of the conductive substrate with a phosphorus source and then performing a firing treatment. Therefore, the operation is simple, convenient and easy to realize.

[0077] In some embodiments of the present invention, the temperature ...

Embodiment 1

[0110] The preparation method of the composite electrode is as follows:

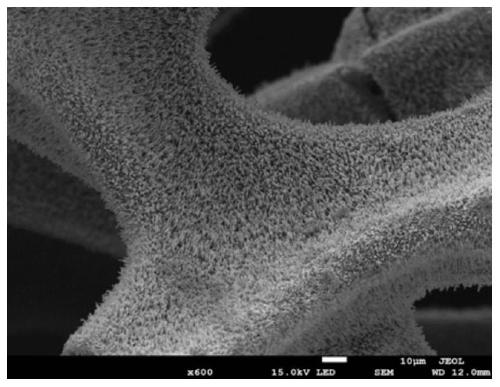

[0111] 1. Prepare 1M hydrochloric acid solution and 1M sodium hydroxide solution respectively; under ultrasonic conditions, place the conductive substrate (foam nickel) in the above-mentioned acid solution, alkali solution, acetone and deionized water in sequence, and ultrasonicate for 10 minutes respectively . Subsequently, the phosphorus source was covered on the surface of the cleaned conductive substrate, placed in an atmosphere furnace and roasted at 500 ° C for 2 hours, and the obtained product was ultrasonically cleaned in deionized water and ethanol for 10 minutes, and then put into vacuum drying for 8 hours to obtain Composite layer (scanning electron microscope (SEM image) of the composite layer can refer to image 3 ).

[0112] 2. In a potassium hydroxide solution at 25°C, anodize the first active material layer with a graphite rod as the cathode and the composite layer as the anode. The ano...

Embodiment 2

[0115] The method for preparing the composite electrode in this example is the same as that in Example 1, except that in the obtained composite electrode, based on the total mass of the first active material layer and the second active material layer, the content of the second active material layer is 2 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com