Preparation method of ultraviolet-proof modified special-shaped nylon filament

An anti-ultraviolet and anti-ultraviolet technology, used in rayon manufacturing, filament/thread forming, melt spinning, etc., can solve the problems of single mode, affect the hand feeling, non-permanent fabric function, etc., to achieve uniform function and better mixing effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

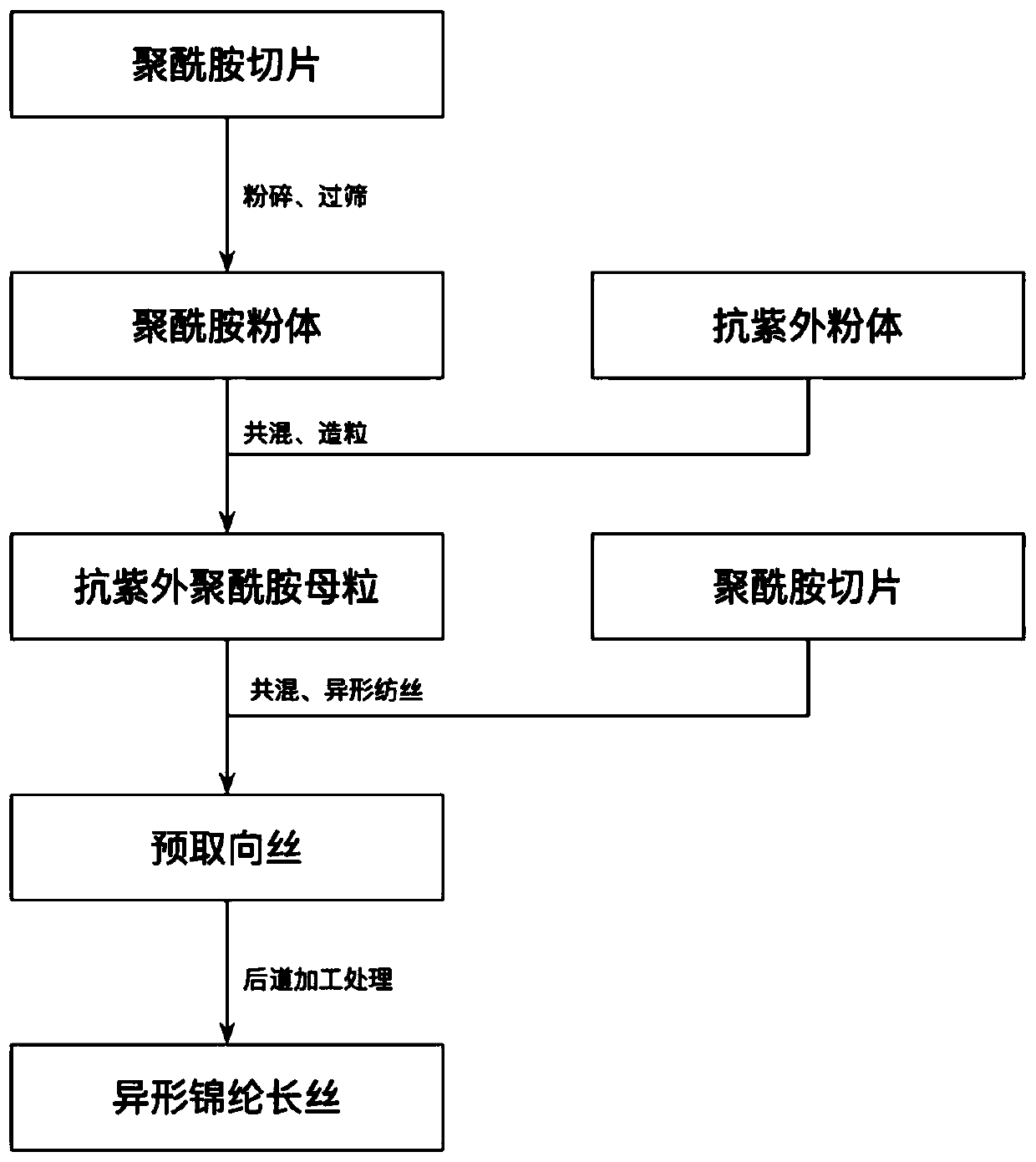

[0026] The invention provides a preparation method of anti-ultraviolet modified special-shaped nylon filament. The cross-section of the anti-ultraviolet modified special-shaped nylon filament is five-pointed star or triangle, and contains ultraviolet shielding powder. The ultraviolet shielding powder is made of titanium zinc metal oxide. One or more kinds are blended, and the mass fraction of the ultraviolet shielding powder in the anti-ultraviolet modified special-shaped nylon filament is 3% to 5%. The preparation method comprises the following steps:

[0027] step one

[0028] The polyamide slices are cryogenically treated, pulverized and sieved to obtain polyamide powder with a mesh size of 150-300. Preferably, the polyamide chips are polyamide 6 chips with a chip viscosity of 2.4-2.7 dL / g.

[0029] Polyamide, also known as nylon, has many excellent properties as a clothing fabric: abrasion resistance, breaking strength, elongation at break, elastic recovery rate, fatigue...

Embodiment 1

[0039] Step (1): The polyamide 6 slices with a slice viscosity of 2.7 dL / g are cryogenically treated, pulverized and sieved to obtain a polyamide powder of 300 mesh.

[0040] Step (2): Titanium dioxide with a particle size of 50 nm is mixed with the polyamide powder obtained in step (1) at a mass ratio of 50:50 at high speed. Then melt blending, extrusion and granulation are carried out through a twin-screw extruder to obtain a modified anti-ultraviolet polyamide masterbatch. The rotation speed of the mixer is 400 rpm, the mixing temperature is 90° C., and the mixing time is 0.5 h.

[0041] Step (3): The modified anti-ultraviolet polyamide masterbatch obtained in step (2) is precisely metered by an injection machine, and then enters the hopper and blends with polyamide 6 slices at a mass ratio of 10:90, followed by melting, extrusion, and profile spinning , oiling, winding and balancing to obtain anti-ultraviolet modified nylon pre-oriented yarn. The special-shaped spinning ...

Embodiment 2

[0049] Step (1): The polyamide 6 slices with a slice viscosity of 2.4 dL / g are cryogenically treated, pulverized and sieved to obtain a polyamide powder of 150 mesh.

[0050] Step (2): Zinc oxide with a particle size of 100 nm is mixed with the polyamide powder obtained in step (1) at a mass ratio of 30:70 at high speed. Then melt blending, extrusion and granulation are carried out through a twin-screw extruder to obtain a modified anti-ultraviolet polyamide masterbatch. The rotation speed of the mixer is 500 rpm, the mixing temperature is 80° C., and the mixing time is 1 h.

[0051] Step (3): The modified anti-ultraviolet polyamide masterbatch obtained in step (2) is precisely metered by an injection machine, and then enters the hopper and blends with polyamide 6 slices at a mass ratio of 15:85, followed by melting, extrusion, profiled spinning, Oiling, winding and balancing to obtain UV-resistant modified nylon pre-oriented yarn. The special-shaped spinning nozzle is "△", ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com