Method for repairing local crack of concrete beam by using shallow embedded shape memory alloy wire

A memory alloy wire and concrete beam technology, which is applied to bridges, bridge parts, bridge materials, etc., can solve the problems of large damage to concrete beams, narrow space, and large loss of prestress, so as to avoid construction difficulties, reduce labor costs, and reduce construction costs. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

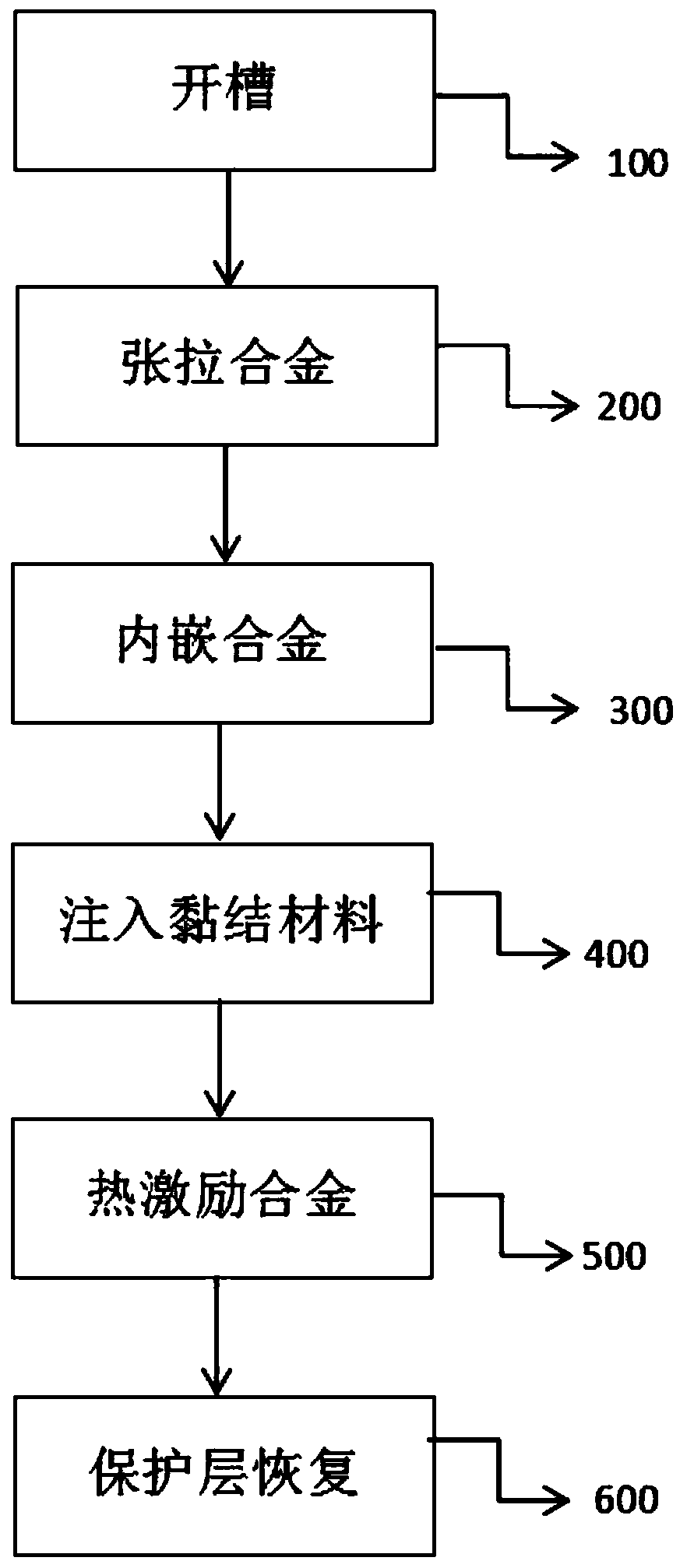

[0046] This embodiment provides a method for repairing local cracks in concrete beams with shallow-buried shape memory alloy wires. The specific steps are:

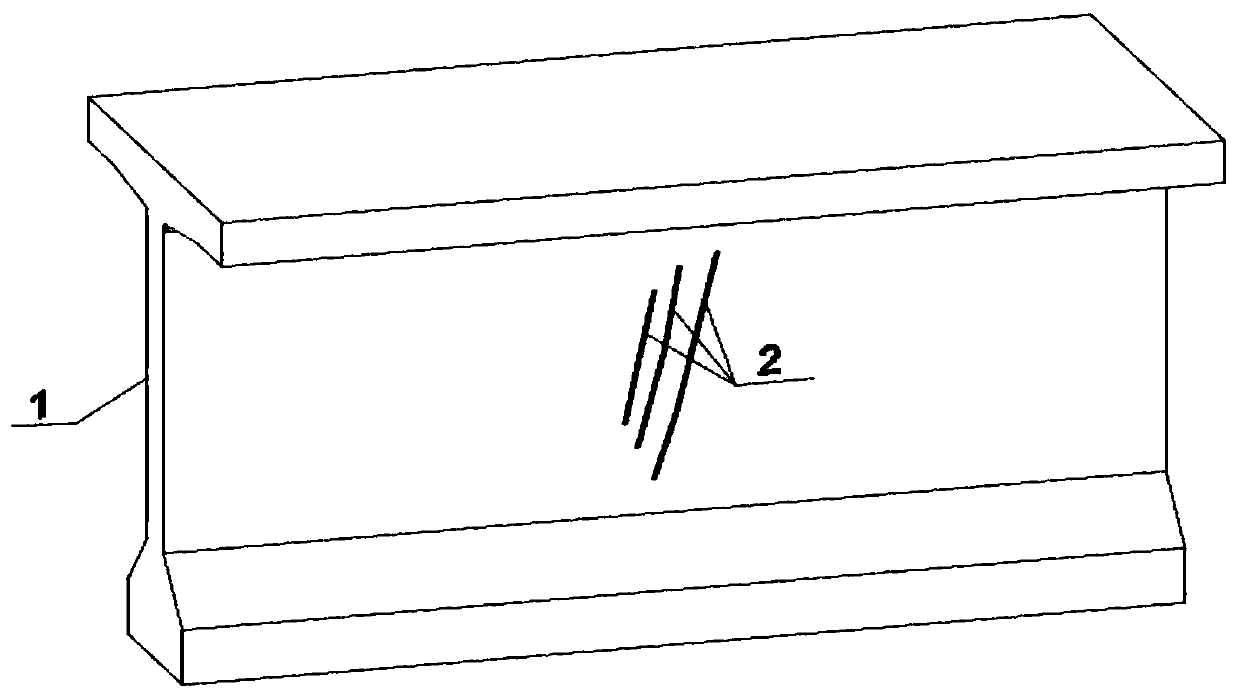

[0047] 100 Grooving: Cut off a certain thickness of the original concrete protective layer at the position where the concrete beam has local cracks, so as to complete the groove within the depth range of the concrete protective layer.

[0048] 200-tension alloy: It is necessary to stretch the alloy to produce a certain pre-strain.

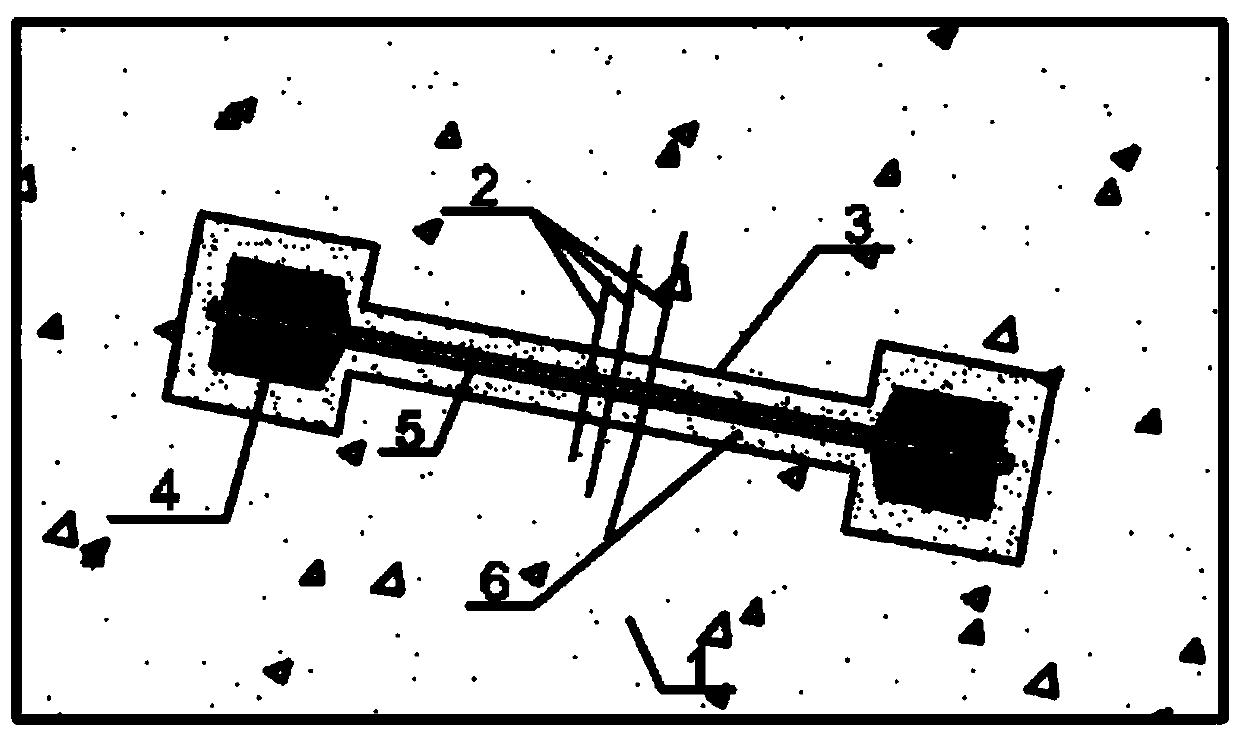

[0049] 300 embedded alloy: the nickel-titanium-niobium shape memory alloy that has been stretched, and the titanium-niobium shape memory alloy is anchored with a flat anchor at the anchoring end.

[0050] 400 Injecting the bonding material: inject the bonding material into the groove.

[0051] 500 thermally actuated alloy: After the bonding material reaches the expected strength, the shape memory alloy is energized and thermally excited to generate a restoring force, and the anchoring force o...

Embodiment 2

[0059] This embodiment further introduces the flat anchor in Example 1. The flat anchor includes an anchor block, several headless hexagon socket screws, threading channels, and screw holes; the anchor block is a hexahedron, along the long axis There is a threading hole in the center, and several staggered screw holes with internal threads are opened on the two sides along the width direction of the anchor block. The depth of the screw hole reaches the threading hole. Thread matching, shape memory alloy for small diameter wire. After passing the shape memory alloy wire through the threading hole, respectively screw the headless hexagon socket head cap screws into the screw holes on both sides of the anchor block, and then tighten and anchor. The flat anchorage has small size, large anchoring force, little damage to concrete structures, effectively solves the anchoring problem of small-diameter shape memory alloy wires, has simple structure, easy installation, and low cost, and...

Embodiment 3

[0061] Usually, after the shape memory alloy wire is embedded in the cracked concrete beam and heated and excited, it is necessary to observe the achieved reinforcement effect. This embodiment provides a device for observing the reinforcement effect, including a loading system and an upper support system; the loading system It includes a lever, a rotating shaft, a balance object, a support column, a bearing plate and a loading object; the lever includes a steel pipe and a steel plate, a balance object is suspended at one end of the steel plate, the other end of the steel plate is connected with one end of the steel pipe, and a load bearing is suspended at the other end of the steel pipe. The loading plate is placed on the loading plate; there is a notch a on the upper surface of the steel plate, the bottom of the rotating shaft is rotatably connected to the notch a, a force sensor is placed on the top of the rotating shaft, and a notch b is opened on the lower surface of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com