Air compressor oil-gas separation core material and its preparation process

An air compressor and core material technology, applied in the field of filter materials and their preparation, can solve problems such as unsatisfactory filtering effect of oil droplets, and achieve the effects of being beneficial to filtering flux and mechanical strength, high speed and large flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

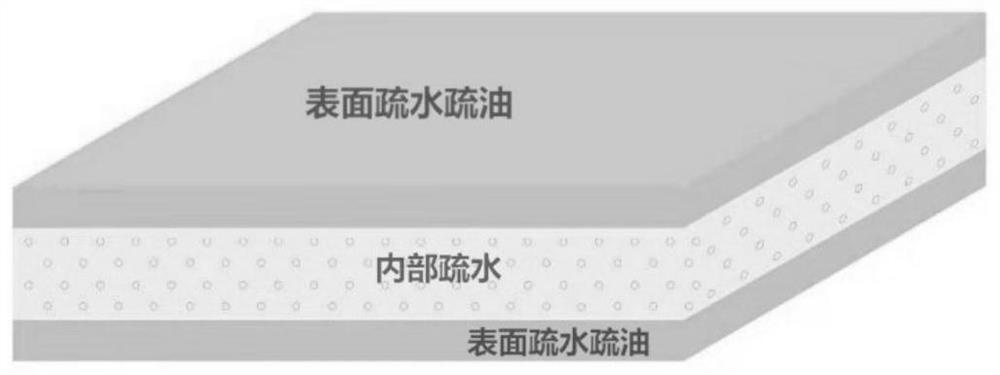

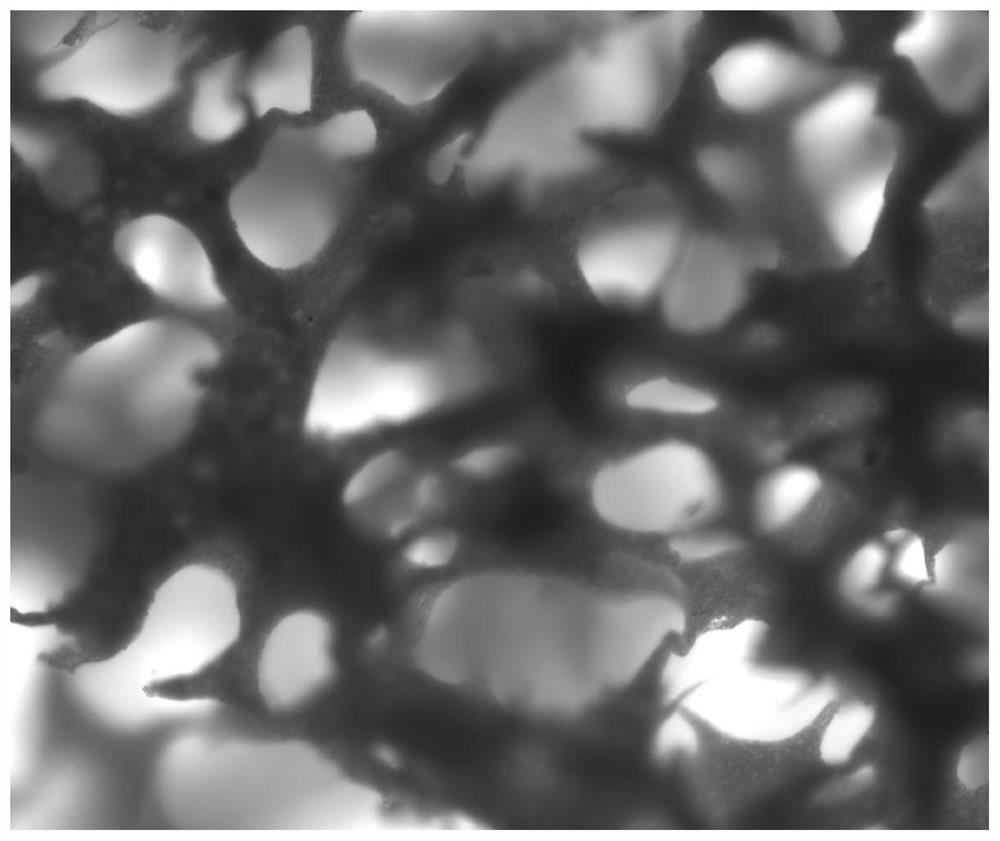

Image

Examples

Embodiment 1

[0036] (1) Add water to 70 parts by weight of PVA17-99 to make a paste, slowly heat and stir until completely dissolved, and control the maximum temperature at 85°C; (2) Stop heating, increase the stirring speed, and add glycerin, formaldehyde, and 202 methyl Hydrogen-containing silicone oil and sodium dodecylbenzenesulfonate, the parts by weight are 30, 100, 10 and 2 parts respectively; (3) Adjust the pH of the reaction system to 4.5 with dilute sulfuric acid; (4) Stir at high speed for 30 minutes; (5) After heat preservation at 50°C for 20 minutes, pour the above materials into a special molding mold; (6) stand at 50°C for 4 hours to obtain a sponge-like product; (7) obtain a filter material blank after washing; (8) cut the filter material to the required Size and thickness; (9) Brush ZHM-2 fluorocarbon resin on the upper and lower surfaces of the filter body, and the brushing amount is 50g / m 2 (ie every 1 m 2 Brush the surface of the filter body with 50g ZHM-2 fluorocarbon...

Embodiment 2

[0039] (1) Add water to 80 parts of PVA17-99 to make a paste, slowly heat and stir until completely dissolved, and control the maximum temperature at 85°C; (2) Stop heating, increase the stirring speed, and add glycerin, formaldehyde, and 202 methyl alcohol in sequence Hydrogen silicone oil and sodium dodecylbenzenesulfonate, the parts by weight are 40, 50, 5 and 3.5 parts respectively; (3) Use dilute sulfuric acid to adjust the pH of the reaction system to 3.5; (4) Stir at high speed for 30 minutes; (5) 50 After keeping warm for 20 minutes at ℃, pour the above materials into a special molding mold; (6) stand at 50°C for 4 hours to obtain a sponge-like product; (7) obtain a filter material blank after washing; (8) cut the filter material to the required size and thickness; (9) Spray Ee602 fluorocarbon surfactant on the upper and lower surfaces of the filter body, 25g / m 2 ; (10) Put the sprayed filter plate into a vacuum drying oven, vacuum degree ≤ 300Pa, heat treatment at 50°...

Embodiment 3

[0041](1) Add water to 90 parts of PVA17-99 to make a paste, heat slowly and stir until it is completely dissolved, and control the maximum temperature to 85°C; (2) Stop heating, increase the stirring speed, and add glycerin, formaldehyde, and RLJJ005 hydrogen-containing silicone oil in sequence And sodium dodecylbenzene sulfonate, the parts by weight are 80, 90, 2 and 10 parts respectively; (3) adjust the pH of the reaction system to 3.5 with dilute sulfuric acid; (4) stir at high speed for 30 minutes; (5) at 50°C After keeping warm for 20 minutes, pour the above materials into a special molding mold; (6) stand at 50°C for 4 hours to obtain a sponge-like product; (7) obtain a filter material blank after washing; (8) cut the filter material to the required size and thickness (9) Spray Ee602 fluorocarbon surfactant on the upper and lower surfaces of the filter body, 100g / m 2 ; (10) Put the sprayed filter plate into a vacuum drying oven, vacuum degree ≤ 300Pa, heat treatment at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com