Modified PP foaming material and preparation method thereof

A foamed material and modified technology, applied in the field of modified PP foamed material and its preparation, can solve the problems of unsatisfactory sound insulation and heat insulation effect, poor foaming effect, weak external force tolerance, etc., and achieve good insulation effect. Thermal effect, improve sound insulation and heat insulation effect, strong resistance to external force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

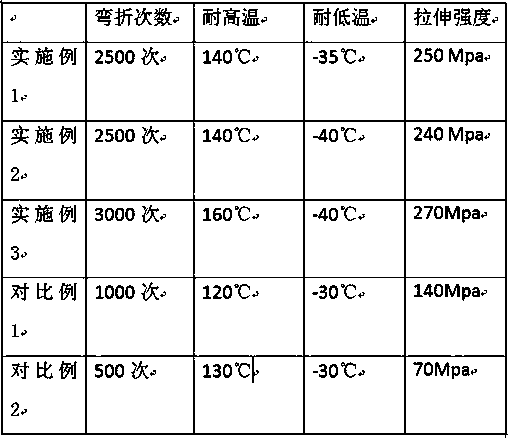

Embodiment 1

[0035] Example 1 A modified PP foam material

[0036] A kind of preparation method of modified PP foam material comprises the following steps:

[0037] Step 1. Raw material preparation

[0038] The raw material that adopts comprises the component of following weight portion:

[0039] 49 parts of PP, 10 parts of polycarbonate, 6 parts of silica gel, 7.5 parts of maleic anhydride graft copolymer, 1 part of calcium carbonate, 9 parts of hydrogenated naphthenic oil, 2 parts of glycerin, and 1.3 parts of special foaming agent.

[0040] The raw material of described special foaming agent comprises: diisopropyl azodicarbonate, azobisisobutyronitrile, Na 2 HCO 3 , copper oxide, sodium stearate, the weight ratio is 4:2:1:0.4:0.8.

[0041] Prepare the raw materials according to the above ratio and set aside.

[0042] Step 2. Premix

[0043] Mix PP, polycarbonate, silica gel, maleic anhydride graft copolymer and calcium carbonate uniformly with a high-speed mixer to obtain a premix...

Embodiment 2

[0055] Example 2 A modified PP foam material

[0056] A kind of preparation method of modified PP foam material comprises the following steps:

[0057] Step 1. Raw material preparation

[0058] The raw material that adopts comprises the component of following weight portion:

[0059] 52 parts of PP, 15 parts of polycarbonate, 10 parts of silica gel, 5 parts of maleic anhydride graft copolymer, 1.5 parts of calcium carbonate, 7 parts of hydrogenated naphthenic oil, 3 parts of glycerin, and 0.9 parts of special foaming agent.

[0060] The raw material of described special foaming agent comprises: diisopropyl azodicarbonate, azobisisobutyronitrile, Na 2 HCO 3 , copper oxide, sodium stearate, the weight ratio is 4:2:1:0.4:0.8.

[0061] Prepare the raw materials according to the above ratio and set aside.

[0062] Step 2. Premix

[0063] Mix PP, polycarbonate, silica gel, maleic anhydride graft copolymer and calcium carbonate uniformly with a high-speed mixer to obtain a prem...

Embodiment 3

[0075] Example 3 A modified PP foam material

[0076] A kind of preparation method of modified PP foam material comprises the following steps:

[0077] Step 1. Raw material preparation

[0078] The raw material that adopts comprises the component of following weight portion:

[0079] 50 parts of PP, 13 parts of polycarbonate, 8 parts of silica gel, 6 parts of maleic anhydride graft copolymer, 1.1 parts of calcium carbonate, 8 parts of hydrogenated naphthenic oil, 2.6 parts of glycerin, and 1.1 parts of special foaming agent.

[0080] The raw material of described special foaming agent comprises: diisopropyl azodicarbonate, azobisisobutyronitrile, Na 2 HCO 3 , copper oxide, sodium stearate, the weight ratio is 4:2:1:0.4:0.8.

[0081] Prepare the raw materials according to the above ratio and set aside.

[0082] Step 2. Premix

[0083] Mix PP, polycarbonate, silica gel, maleic anhydride graft copolymer and calcium carbonate uniformly with a high-speed mixer to obtain a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com