A kind of heavy metal polluted soil remediation agent and preparation method thereof

A technology of contaminated soil and remediation agent, which is applied in the field of heavy metal contaminated soil remediation agent, which can solve the problems of incomplete and complete elimination of soil heavy metals, secondary pollution, and damage to soil structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

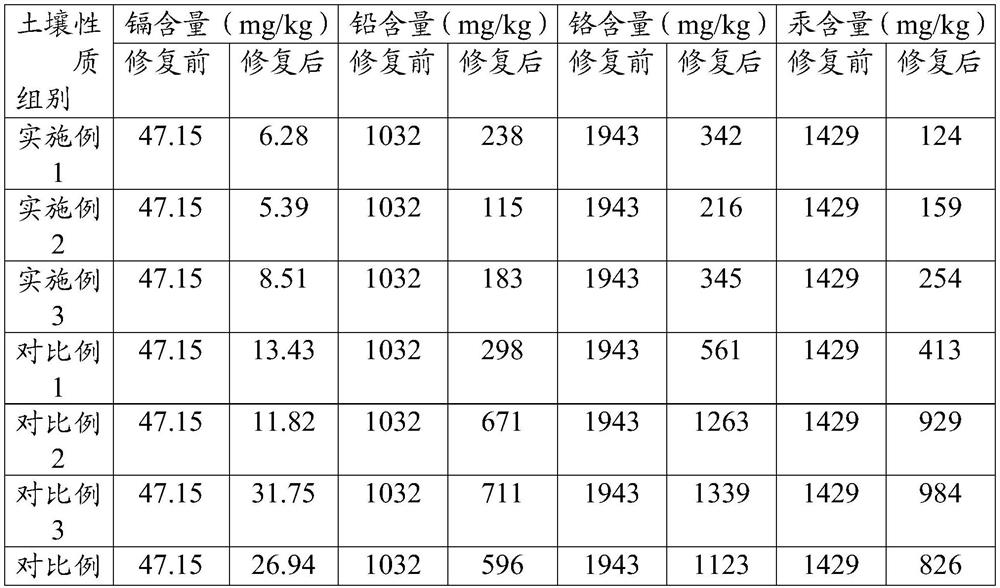

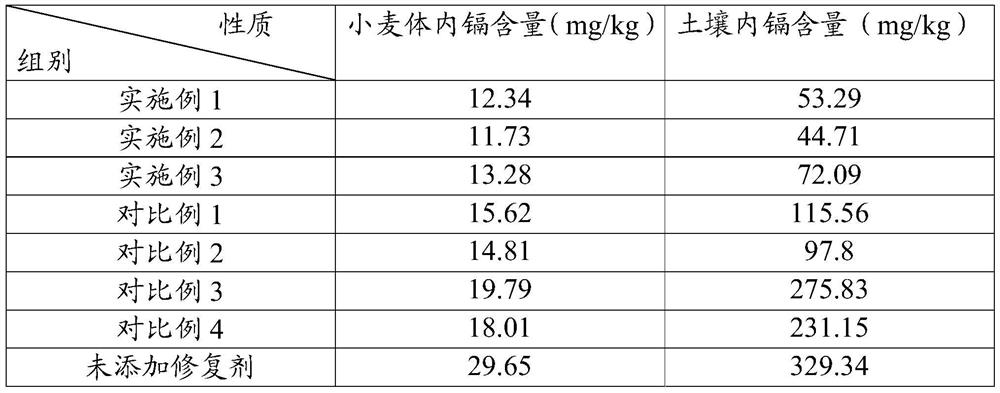

Examples

Embodiment 1

[0032] This embodiment provides a heavy metal contaminated soil remediation agent, consisting of the following raw materials in parts by mass:

[0033] 57 parts of modified biochar, 25 parts of organic matter, 10 parts of compound microbial agent, 7 parts of polyacrylamide, 16 parts of organic fertilizer, 9 parts of iron powder;

[0034] Wherein organic matter is obtained by mixing humic acid, potassium humate and potassium fulvic acid according to a mass ratio of 3:7:3;

[0035] Wherein the composite microbial bacterial agent is composed of the following raw materials by mass: 2.5 parts of Bacillus cereus, 2 parts of Clostridium perfringens, 3 parts of Bacillus mycoides, 2.5 parts of Bacillus colloidus, 8.5 parts of white rot fungus, lemon 3.5 parts of Acidobacillus, 4 parts of Streptomyces griseus, 2.5 parts of Pseudomonas aeruginosa; the effective number of viable bacteria of each bacteria in the composite microbial agent is 1×10 9 CFU / g.

[0036] The present embodiment a...

Embodiment 2

[0043] This embodiment provides a heavy metal contaminated soil remediation agent, consisting of the following raw materials in parts by mass:

[0044] 50 parts of modified biochar, 20 parts of organic matter, 6 parts of compound microbial agent, 5 parts of polyacrylamide, 12 parts of organic fertilizer, 6 parts of iron powder;

[0045] Wherein the organic matter is obtained by mixing humic acid, potassium humate and potassium fulvic acid in a mass ratio of 2:6:3;

[0046] Wherein the composite microbial bacterial agent is composed of the following raw materials by mass: 1 part of Bacillus cereus, 1 part of Clostridium perfringens, 1 part of Bacillus mycoides, 2 parts of Bacillus colloidus, 5 parts of white rot fungus, lemon 2 parts of Acidobacillus, 3 parts of Streptomyces griseus, 1 part of Pseudomonas aeruginosa; the effective number of viable bacteria of each bacteria in the composite microbial agent is 2×10 9 CFU / g.

[0047] The present embodiment also provides the prep...

Embodiment 3

[0054] This embodiment provides a heavy metal contaminated soil remediation agent, consisting of the following raw materials in parts by mass:

[0055] 65 parts of modified biochar, 30 parts of organic matter, 15 parts of compound microbial agent, 10 parts of polyacrylamide, 20 parts of organic fertilizer, 12 parts of iron powder;

[0056] Wherein the organic matter is obtained by mixing humic acid, potassium humate and potassium fulvic acid in a mass ratio of 4:8:3;

[0057] Wherein the composite microbial bacterial agent consists of the following raw materials by mass: 4 parts of Bacillus cereus, 3 parts of Clostridium perfringens, 5 parts of Bacillus mycoides, 3 parts of Bacillus colloidus, 12 parts of white rot fungus, lemon 5 parts of Acidobacillus, 5 parts of Streptomyces griseus, 4 parts of Pseudomonas aeruginosa; the effective number of viable bacteria of each bacteria in the composite microbial agent is 3×10 9 CFU / g.

[0058] The present embodiment also provides the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com