Wave absorbing structure

A wave structure and support layer technology, applied in the field of wave-absorbing materials, can solve the problems of wave incident angle sensitivity and narrow action frequency band, and achieve the effect of wide absorption frequency band, high absorption efficiency, and better design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

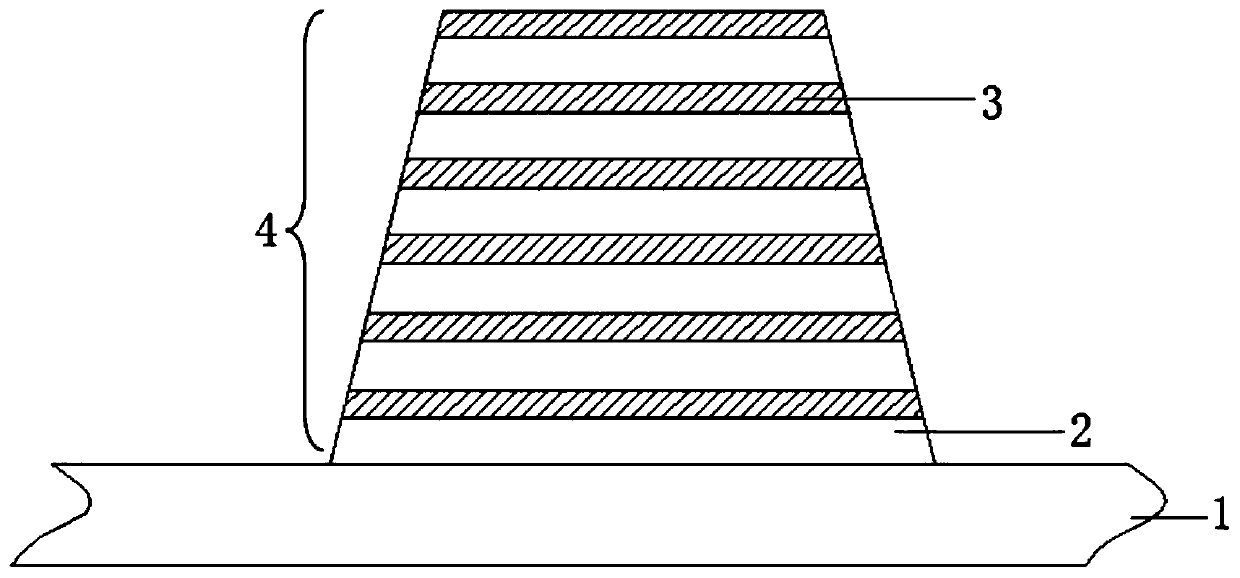

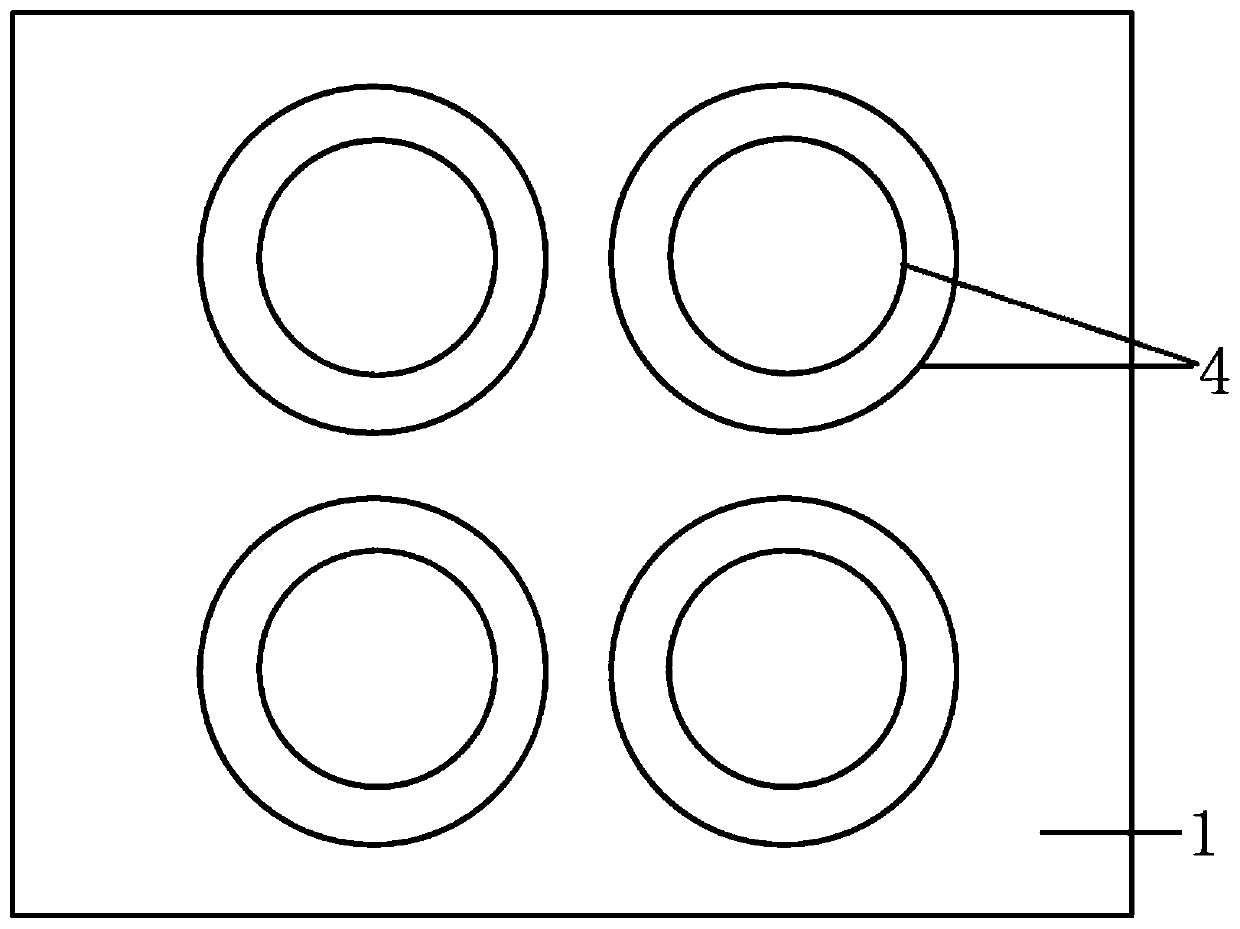

[0025] like figure 1 and figure 2 As shown, the absorbing structure of this embodiment includes a support layer 1 and a plurality of superatoms 4 arranged in an array on the support layer 1, and the superatoms 4 are periodically formed by the dielectric layer 2 and the metal layer 3 from bottom to top. Superimposed to form a conical structure, the material of the support layer 1 is epoxy glass FR-4, the dielectric constant is 4, and the thickness is 2mm; the material of the dielectric layer 2 is epoxy glass FR-4, and the thickness is 0.182mm The metal layer 3 is made of copper with a thickness of 0.036mm; the number of layers of the dielectric layer 2 and the metal layer 3 periodically stacked is 29 layers; the bottom diameter of the superatom 4 is 25mm, and the top diameter is 12mm ; The distance between the centerlines of the adjacent superatoms 4 is 24mm.

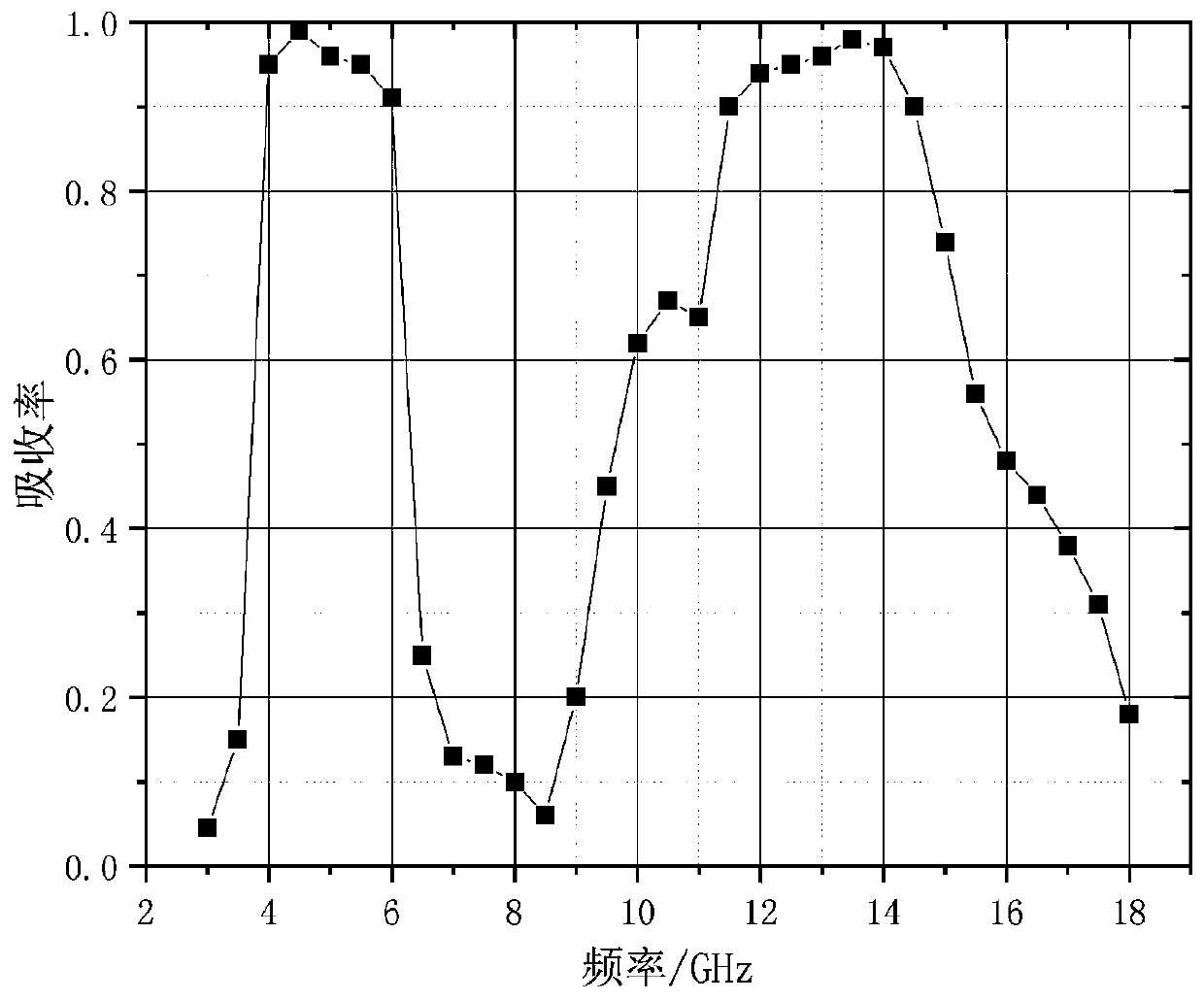

[0026] When microwave electromagnetic radiation is incident on the surface of the wave-absorbin...

Example Embodiment

[0028] Example 2

[0029] like figure 1 and figure 2 As shown, the absorbing structure of this embodiment includes a support layer 1 and a plurality of superatoms 4 arranged in an array on the support layer 1, and the superatoms 4 are periodically formed by the dielectric layer 2 and the metal layer 3 from bottom to top. Superimposed to form a conical structure, the material of the support layer 1 is silicon, and the thickness is 100nm; the material of the dielectric layer 2 is silicon, and the thickness is 40nm; the material of the metal layer 3 is gold, and the thickness is 5nm; The number of layers of dielectric layer 2 and metal layer 3 stacked periodically is 4 layers; the diameter of the bottom of the superatom 4 is 350mm, and the diameter of the top is 220mm; the distance between the centerlines of the adjacent superatoms 4 is 400nm.

[0030] When infrared and visible light electromagnetic radiation is incident on the surface of the wave-absorbing structure of this e...

Example Embodiment

[0031] Example 3

[0032] like figure 1 and figure 2As shown, the absorbing structure of this embodiment includes a support layer 1 and a plurality of superatoms 4 arranged in an array on the support layer 1, and the superatoms 4 are periodically formed by the dielectric layer 2 and the metal layer 3 from bottom to top. Superimposed to form a conical structure, the material of the support layer 1 is epoxy glass FR-4, the dielectric constant is 4, and the thickness is 2mm; the material of the dielectric layer 2 is epoxy glass FR-4, and the thickness is 0.1mm The material of the metal layer 3 is silver, with a thickness of 0.01mm; the number of layers of the dielectric layer 2 and the metal layer 3 periodically stacked is 50 layers; the bottom diameter of the superatom 4 is 25mm, and the top diameter is 12mm ; The distance between the centerlines of the adjacent superatoms 4 is 50mm.

[0033] When microwave electromagnetic radiation is incident on the surface of the wave-abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap