Making process of flower tea

A production process, scented tea technology, applied in the direction of tea substitutes, etc., can solve the problems of messy kneading direction, excessive debris, unreasonable, etc., and achieve the effect of reducing the probability of breaking, reducing bitterness, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

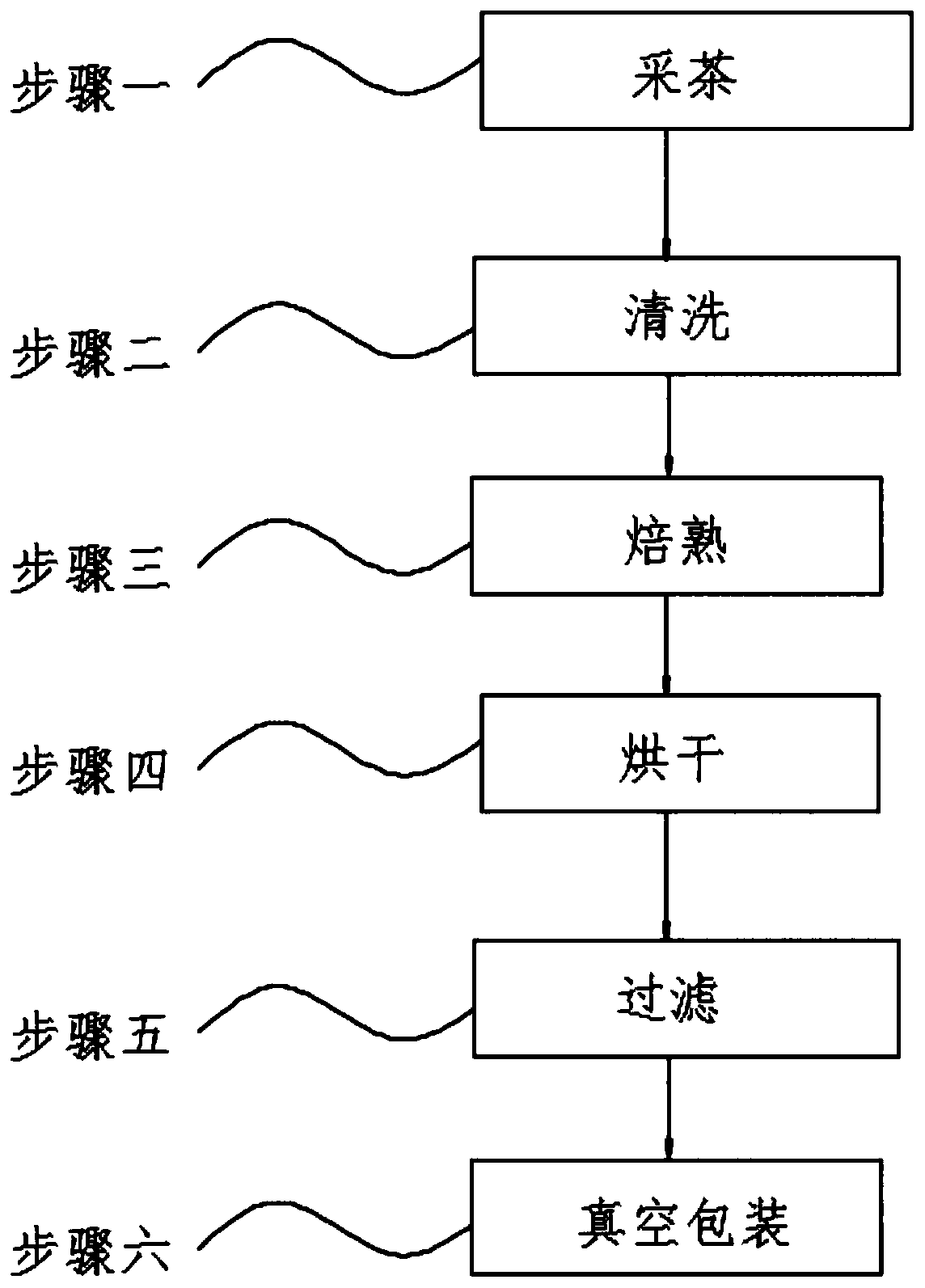

[0024] A manufacturing process of scented tea, comprising step 1, picking tea; step 2, cleaning; step 3, roasting; step 4, drying; step 5, filtering; step 6, vacuum packaging;

[0025] Wherein in above-mentioned step one, take the flower bud that flower bud is to be opened in tea garden;

[0026] Wherein in the above step 2, the petals of the picked flower buds are taken out, soaked for 1-2 hours, the temperature of the soaking water is set to 30-40°C, and the stamens and flower pedicles are removed. cleaning of dust;

[0027] Wherein in the above step 3, after the cleaned petals are filtered, they are placed on the steamer at a temperature of 50-60° C. for 1 hour. During the steaming process, every Turn over once every 10 minutes. After baking, let it dry to room temperature, then knead it manually, and keep kneading in one direction;

[0028] Wherein in the above step 4, after baking, the petals are placed in a sterile room for drying for 1 to 2 days at a drying temperatur...

Embodiment 2

[0032] A manufacturing process of scented tea, comprising step 1, picking tea; step 2, cleaning; step 3, roasting; step 4, drying; step 5, filtering; step 6, vacuum packaging;

[0033] Wherein in above-mentioned step one, take the flower bud that flower bud is to be opened in tea garden;

[0034] Wherein in the above step 2, the petals of the picked flower buds are taken out, soaked for 1-2 hours, the temperature of the soaking water is set to 30-40°C, and the stamens and flower pedicles are removed. cleaning of dust;

[0035] Wherein in the above step 3, after the cleaned petals are filtered, they are placed on the steamer at a temperature of 50-60°C for 1.5 hours. During the steaming process, each Turn over once every 10 minutes. After baking, let it dry to room temperature, then knead manually, and keep kneading in one direction;

[0036] Wherein in the above step 4, after baking, the petals are placed in a sterile room for drying for 1 to 2 days at a drying temperature o...

Embodiment 3

[0040] A manufacturing process of scented tea, comprising step 1, picking tea; step 2, cleaning; step 3, roasting; step 4, drying; step 5, filtering; step 6, vacuum packaging;

[0041] Wherein in above-mentioned step one, take the flower bud that flower bud is to be opened in tea garden;

[0042] Wherein in the above step 2, the petals of the picked flower buds are taken out, soaked for 1-2 hours, the temperature of the soaking water is set to 30-40°C, and the stamens and flower pedicles are removed. cleaning of dust;

[0043] Among them, in the above step three, after the cleaned petals are filtered, they are placed on the steamer at a temperature of 50-60° C. for 2 hours. During the steaming process, every Turn over once every 10 minutes. After baking, let it dry to room temperature, then knead it manually, and keep kneading in one direction;

[0044] Wherein in the above step 4, after baking, the petals are placed in a sterile room for drying for 1 to 2 days at a drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com