Method of extracting high-purity cannabidiol from industrial hemp

A technology of cannabidiol and industrial hemp, which is applied in the field of medicine, can solve the problems of unspecified waste disposal and other issues, and achieve the effects of stable product quality, low operating pressure, and reduced dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

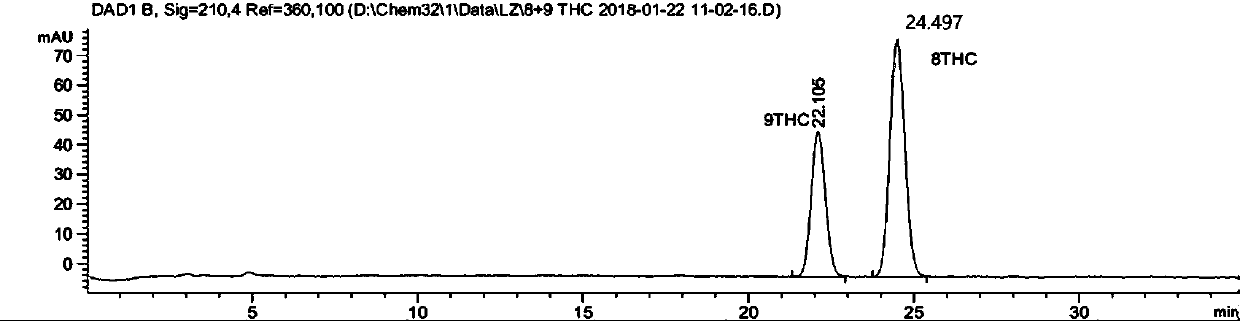

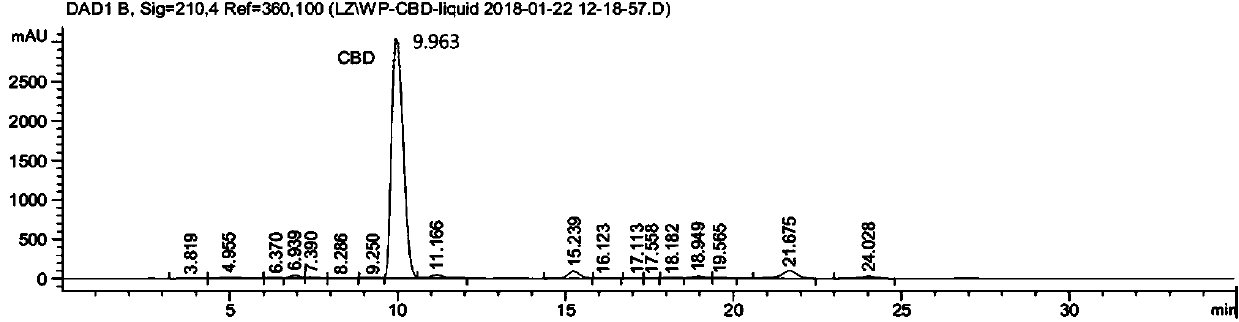

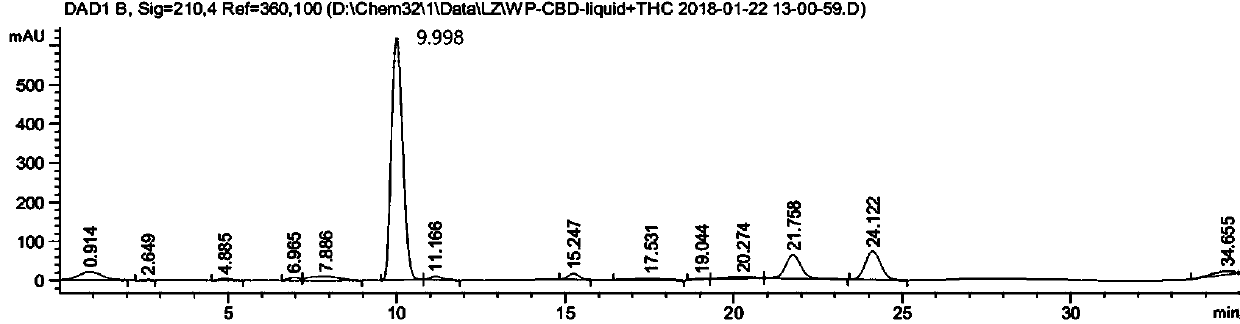

Image

Examples

Embodiment 1

[0110] Pick the cannabis flowers and leaves to remove impurities such as branches and gravel, and then dry them in the shade. Grinding with a pulverizer with dust removal function, the mesh of the crushing screen is 50 mesh, the powder is sent to the mixer, and the moisture is measured with a simple moisture meter to control the moisture content of the powder to 4-8%, and then sent to the granulator for granulation , the diameter of the prepared particles is 1 cm, and the length is 2 to 4 cm. Take 5 kg of the prepared particles and put them into an extraction bag, place them in a 29L extraction tank, inject liquid natural gas after vacuuming until the solid particles are covered, but not more than 4 / 5 of the total volume of the tank, and the temperature of the extraction tank rises to 40°C And last for 30 minutes, then transfer the extract into the evaporation tank, reduce the pressure and increase the temperature to vaporize the liquid natural gas, then transfer it to the nat...

Embodiment 2

[0112] Pick the cannabis flowers, leaves and seed shells to remove impurities such as branches and gravel, and then dry them in the shade. Grinding with a pulverizer with dust removal function, the mesh number of the crushing screen is 24 mesh, the powder is sent to the mixer, and the moisture is measured with a simple moisture meter to control the moisture content of the powder to 4-8%, and then sent to the granulator for granulation , the diameter of the prepared particles is 1 cm, and the length is 2 to 4 cm. Get 5 kilograms of the granules prepared in Example 1 and put them into an extraction bag, place them in a 29L extraction tank, inject liquid butane after vacuuming until the solid particles are covered, but not exceed 4 / 5 of the total volume of the tank, the temperature of the extraction tank Raise to 35-40°C and maintain for 20 minutes, then transfer the extract to an evaporation tank, reduce pressure and increase temperature to vaporize the butane, then transfer it ...

Embodiment 3

[0114] Take 5 kilograms of the granules prepared in Example 2 and put them into an extraction bag, place them in a 29L extraction tank, inject liquid butane after vacuuming until the solid particles are covered, but not exceed 4 / 5 of the total volume of the tank, and the extraction tank The temperature is raised to 35-40°C and maintained for 30 minutes, then the extract is transferred to an evaporation tank, the butane is vaporized by increasing the pressure under reduced pressure and then transferred to a butane storage tank through a compressor, and the unvaporized extract is collected. Extracted twice, samples were analyzed by HPLC, and the extraction rate of CBD was calculated according to the peak area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com