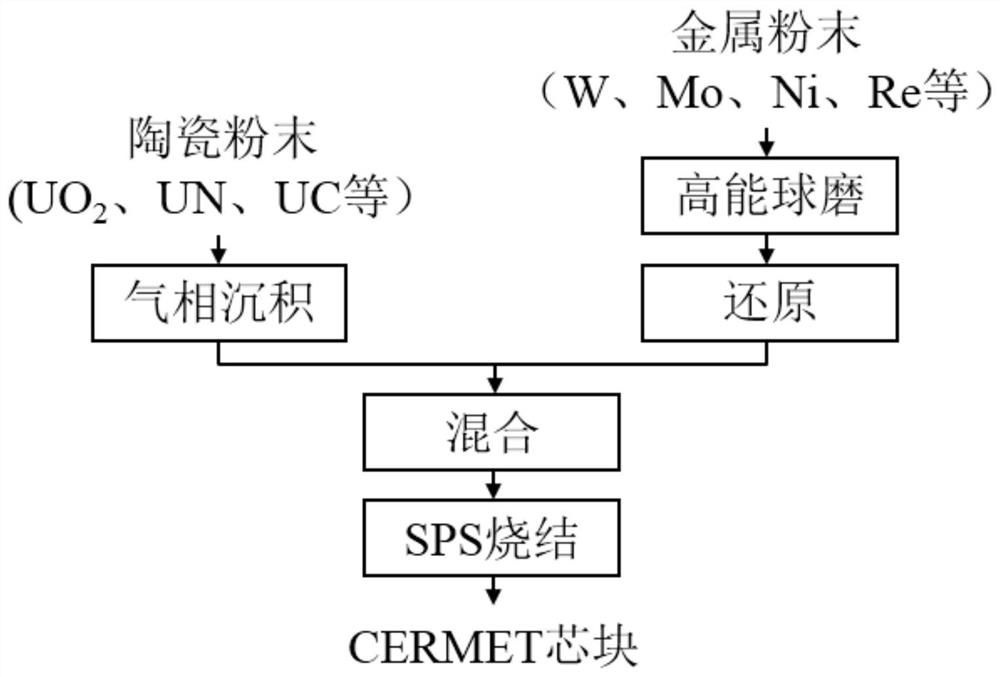

A kind of spark plasma sintering preparation method of cermet fuel pellets

A technology of discharge plasma and fuel pellets, which is applied in nuclear power generation, manufacturing reactors, metal processing equipment, etc., can solve the problems of high sintering temperature, inability to apply CERMET pellets, etc. , Reduce the effect of production energy consumption and equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation of CERMET fuel pellets by spark plasma sintering (1)

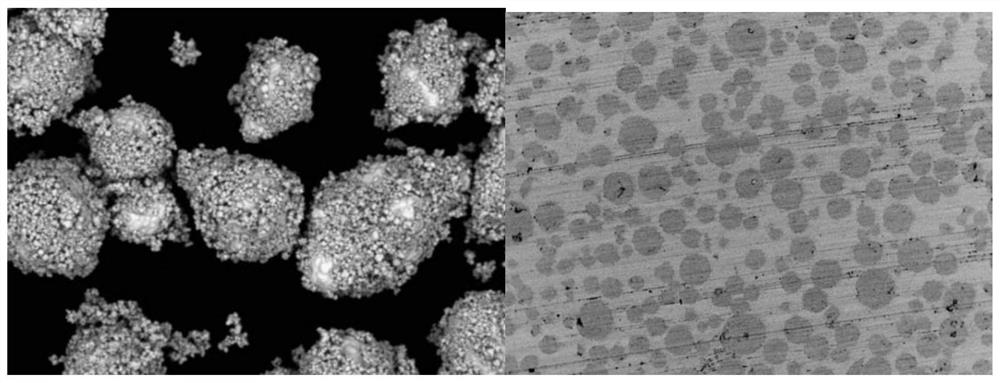

[0039] Weigh 33.89g of UN powder, and deposit a layer of metal Mo layer on the surface of UN powder particles by vapor deposition process for later use.

[0040] Weigh 16.11g metal Mo powder, and ZrO 2 ZrO 2 The ball mill tank is used for high-energy ball milling, and the conditions are: the volume ratio of balls to materials is 5:1, the milling speed is 400 rpm, and the ball milling time is 24 hours. During the milling process, the milling jar is filled with inert gas for protection. Open the ball mill jar in an inert gas glove box, and separate the milled balls. Put the ball-milled metal Mo powder into the Mo crucible, transfer it into the atmosphere furnace, turn on the heating, and continuously feed high-purity H 2 The gas is used to reduce the metal Mo powder, and the reduction temperature is 400°C.

[0041] The metal Mo powder after reduction treatment and the UN powder treated by v...

Embodiment 2

[0043] Example 2: Preparation of CERMET fuel pellets by spark plasma sintering (2)

[0044] Weigh 23g UO 2 powder, using a vapor deposition process at UO 2 Deposit a layer of metal W layer on the surface of the powder particles for later use;

[0045] Weigh 27g of metal W powder, put it into a W ball mill tank together with W balls for high energy ball milling, the conditions are: the volume ratio of balls to material is 10:1, the milling speed is 800 rpm, and the ball milling time is 8 hours. During the milling process, the milling jar is filled with inert gas for protection. Open the ball mill jar in an inert gas glove box, and separate the milled balls. Put the ball-milled metal W powder into the W crucible, transfer it into the atmosphere furnace, turn on the heating, and continuously feed high-purity H 2 The gas is used to reduce the metal W powder, and the reduction temperature is 800°C.

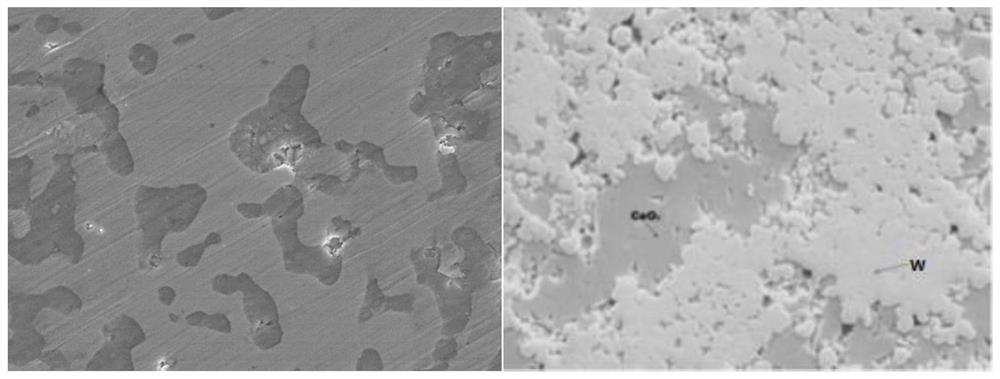

[0046] Combine the reduced metal W powder with the vapor-deposited UO 2 The ...

Embodiment 3

[0048] Example 3: Preparation of CERMET fuel pellets by spark plasma sintering (3)

[0049] Weigh 34.72g UO 2 powder, using a vapor deposition process at UO 2 A layer of metal W layer is deposited on the surface of the powder particles for later use.

[0050] Weigh 15.28g of metal W powder, and put it into a W ball mill tank together with W balls for high-energy ball milling. The conditions are: the ball-to-material volume ratio is 7:1, the milling speed is 600 rpm, and the ball milling time is 16 hours. During the milling process, the milling jar is filled with inert gas for protection. Open the ball mill jar in an inert gas glove box, and separate the milled balls. Put the ball-milled metal W powder into the W crucible, transfer it into the atmosphere furnace, turn on the heating, and continuously feed high-purity H 2 The gas is used to reduce the metal W powder, and the reduction temperature is 700°C.

[0051] Combine the reduced metal W powder with the vapor-deposited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com