A kind of preparation method of layered copper chromium zirconium-pure copper composite plate

A composite plate, copper chromium zirconium technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of poor interface bonding, low material utilization, and limited material strength improvement, so as to avoid grain recovery or Recrystallization, improving comprehensive mechanical properties, and realizing the effect of back stress strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a layered copper-chromium-zirconium-pure copper heterogeneous composite plate, comprising the following steps:

[0034] (1) Plate cutting and surface deoxidation treatment

[0035] Cut the copper-chromium-zirconium (C18150 grade) and pure copper (T2 grade) plates with a thickness of 0.1-5mm into the same length and width dimensions, and the thickness ratio of the copper-chromium-zirconium and pure copper layers is 7:3 (according to literature and theory It is concluded that the ratio of soft and hard phases is 3:7, which is the ratio with the best back stress strengthening effect (because the soft phase mainly provides electrical conductivity and plasticity, too high a ratio will lead to insufficient strength; while the hard phase mainly provides strength and hardness, too high a ratio High conductivity and plasticity will decrease)), at least two layers, the more layers the better (because the back stress strengthening mainly depends on the effec...

Embodiment 1

[0045] First of all, this embodiment adopts the following equipment: high temperature diffusion pressure welding equipment, Two-roll reversible temperature rolling mill, tube furnace with protective gas filling for heat treatment.

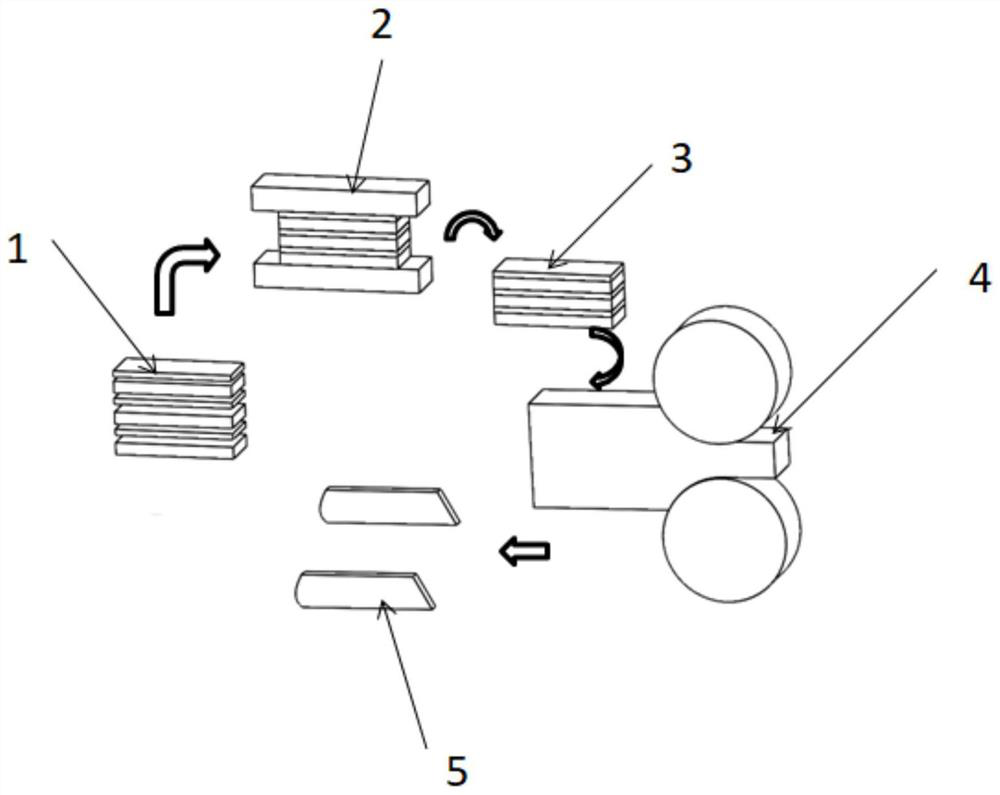

[0046] The process flow chart for preparing a layered copper chromium zirconium-pure copper heterogeneous composite plate in this example is as follows figure 1 As shown, the specific operation is as follows:

[0047] The pure copper used in this embodiment is 0.5mm, the thickness of the copper-chromium-zirconium plate is 1mm, and the size is 200×200mm 2, the chemical composition (wt.%) of pure copper used is: Cu: 99.94, Zn: 0.0041, Pb: 0.0007, Sn: 0.0005, Fe: 0.0031, Ni: 0.0028, Si: 0.028, and the rest are unavoidable impurities , the chemical composition (wt.%) of copper, chromium and zirconium is: Cu: 99.1565, Cr: 0.732, Zr: 0.067, Al: 0.001, Fe: 0.022, Mg: 0.014, P: 0.0005, Si: 0.007, and the rest are unavoidable of impurities.

[0048] Se...

Embodiment 2

[0056] First of all, this embodiment adopts the following equipment: high temperature diffusion pressure welding equipment, Two-roll reversible temperature rolling mill, tube furnace with protective gas filling for heat treatment.

[0057] The process flow chart for preparing a layered copper chromium zirconium-pure copper heterogeneous composite plate in this example is as follows figure 1 As shown, the specific operation is as follows:

[0058] The pure copper used in this embodiment is 0.5mm, the thickness of the copper-chromium-zirconium plate is 1mm, and the size is 200×200mm 2 , the chemical composition (wt.%) of pure copper used is: Cu: 99.94, Zn: 0.0041, Pb: 0.0007, Sn: 0.0005, Fe: 0.0031, Ni: 0.0028, Si: 0.028, and the rest are unavoidable impurities , the chemical composition (wt.%) of copper, chromium and zirconium is: Cu: 99.1565, Cr: 0.732, Zr: 0.067, Al: 0.001, Fe: 0.022, Mg: 0.014, P: 0.0005, Si: 0.007, and the rest are unavoidable of impurities.

[0059] S...

PUM

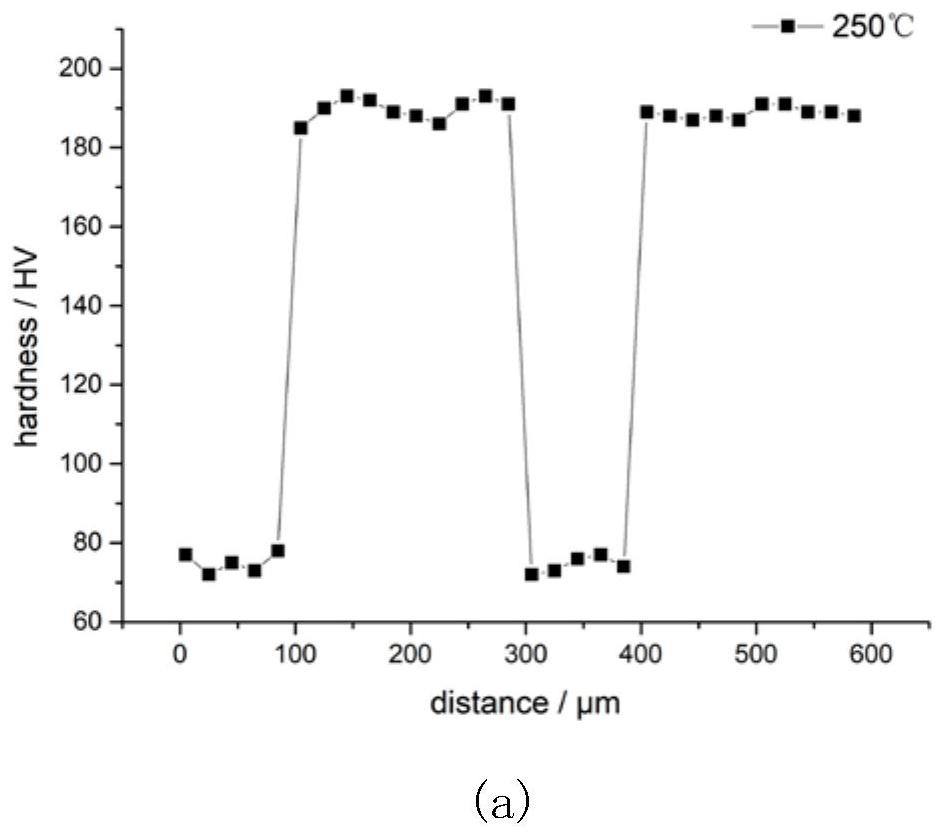

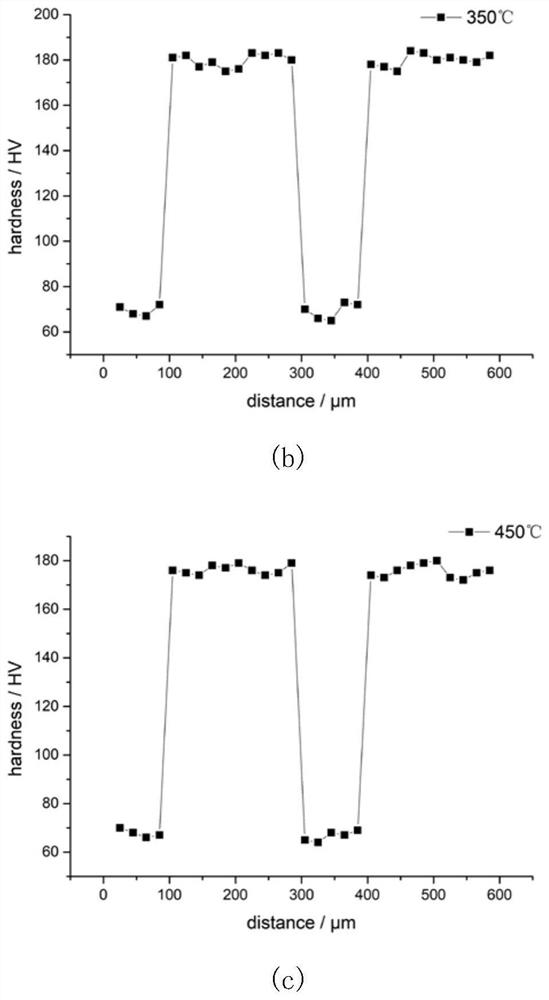

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com